I guess that could arguably be the best assumption of all - coming from the guy that makes it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tiramisu Fujiwara Denka vs Maboroshi

- Thread starter sliceanddicebaby

- Start date

Help Support Kitchen Knife Forums:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

sliceanddicebaby

Well-Known Member

I guess that could arguably be the best assumption of all - coming from the guy that makes it.

He's a few decades removed from the forge, and he's moved on to katanas with sh*tty overgrinds. Trust 0/10.

So we’re buying NON-TFTFTFTF now. Good to know - like mine Mabs but won’t go further this way.

Larrin

Senior Member

- Joined

- Mar 13, 2011

- Messages

- 723

- Reaction score

- 1,033

I don’t know if it was the forging of the 1.2562 that improved properties or the marquench so I can’t comment on what led to improvement. More tests will be performed in the future.

But I will say in general that very high carbon low alloy steels do not have impressive toughness. A more general article on that subject would be here: Ranking Toughness of Forging Knife Steels - Knife Steel Nerds

And in general I have found Japanese carbon steel knives to be relatively brittle.

But I will say in general that very high carbon low alloy steels do not have impressive toughness. A more general article on that subject would be here: Ranking Toughness of Forging Knife Steels - Knife Steel Nerds

And in general I have found Japanese carbon steel knives to be relatively brittle.

Exactly the one I was searching for thanks so much!

"26C3 has relatively high carbon but is only alloyed with a small amount of chromium so it has a more even microstructure than the above high-tungsten steels. The carbides are still significantly larger than a steel like 52100, however. I would expect Hitachi White #1 to have a similar microstructure. 26C3 has relatively high carbon in solution and carbide volume but has decent toughness. I’m not sure what would make it have better toughness than a steel like O1 or 1095, for example. Maybe the superior cleanliness (low impurity elements) advertised by Uddeholm actually does lead to an improvement."

Interesting to me...

Interesting to me...

Did someone say that current TF knives are not forged by TF?

Yep @sliceanddicebabyDid someone say that current TF knives are not forged by TF?

Tiramisu Fujiwara...? U meant Teruyasu Fujiwara right...?

You’re missing on the tremendous fun of a bunch of initial replies...

BillHanna

Gotta get ready for ARM

You don’t find biweekly tftftftf discussions delicious?Tiramisu Fujiwara...? U meant Teruyasu Fujiwara right...?

sliceanddicebaby

Well-Known Member

Tiramisu Fujiwara...? U meant Teruyasu Fujiwara right...?

Did I?

Did someone say that current TF knives are not forged by TF?

99% sure TF does not make all of his knives. He has many apprentices and masters working with him - he's not sitting there hammering out nashiji petties.

I guess what I care about the most is the Denka line, any guess?99% sure TF does not make all of his knives. He has many apprentices and masters working with him - he's not sitting there hammering out nashiji petties.

sliceanddicebaby

Well-Known Member

I guess what I care about the most is the Denka line, any guess?

Your guess is as good as mine. I know he does not make every denka, though - and I doubt they'd tell you who made it. Maybe if you've spent "happy time" and maybe 10k USD with TF, who knows...

Paging @lemeneid and @Corradobrit1 to provide more unsubstantiated anecdotal lore and muddy the waters further.

parbaked

Senior Member

He's not forging your Denka but he will scratch your name on it for free!I guess what I care about the most is the Denka line, any guess?

The forge is not in the same location as the shop, where he spends most of his time.

A team of craftsmen collaborate on each knife, except for the western handles which are made by either child or prison labor.

TFTFTFTF

I love mine...

You won't know unless you get to try one, arghhhhh

Last edited:

- Joined

- May 1, 2012

- Messages

- 4,099

- Reaction score

- 10,682

...and chances are a Denka doesn’t even do that.Tiramisu only offers momentary pleasure

Would it not mean more now that TF doesn't forge knives anymore? Or do they still put the toucou stamp on knives produced today? Just asking because I do not know.Also toucou means squat nowadays, TF doesn’t forge knives anymore nor is it an indication of quality.

And the hand chiseled kanji is tacky AF.

Corradobrit1

Senior Member

- Joined

- May 2, 2015

- Messages

- 6,828

- Reaction score

- 6,876

No they don't mark the blades with tou cou anymore, and haven't for years. The one I picked up in 2018 was a 5+ year old NOS 210 Denka. Some western dealers like Knifewear still had a couple when I was looking.Would it not mean more now that TF doesn't forge knives anymore? Or do they still put the toucou stamp on knives produced today? Just asking because I do not know.

nakiriknaifuwaifu

Senior Member

No they don't mark the blades with tou cou anymore, and haven't for years. The one I picked up in 2018 was a 5+ year old NOS 210 Denka. Some western dealers like Knifewear still had a couple when I was looking.

This one purchased in 2019 did.

I just wanted to make this post showing how I did the initial sharpening on this knife. I’ve been hand sharpening for about 5 years, and only recently bought Japanese knives. This is my second full sharpening to include thinning. I hope someone else sees this and realizes they can do this work if they decide to, without an insane amount of skill, belt sanders, JNats, or expecting perfect results. Here was my process and the results. I made a few different decisions on this knife than the last time I did it, and next time I will apply lessons learned to the next.

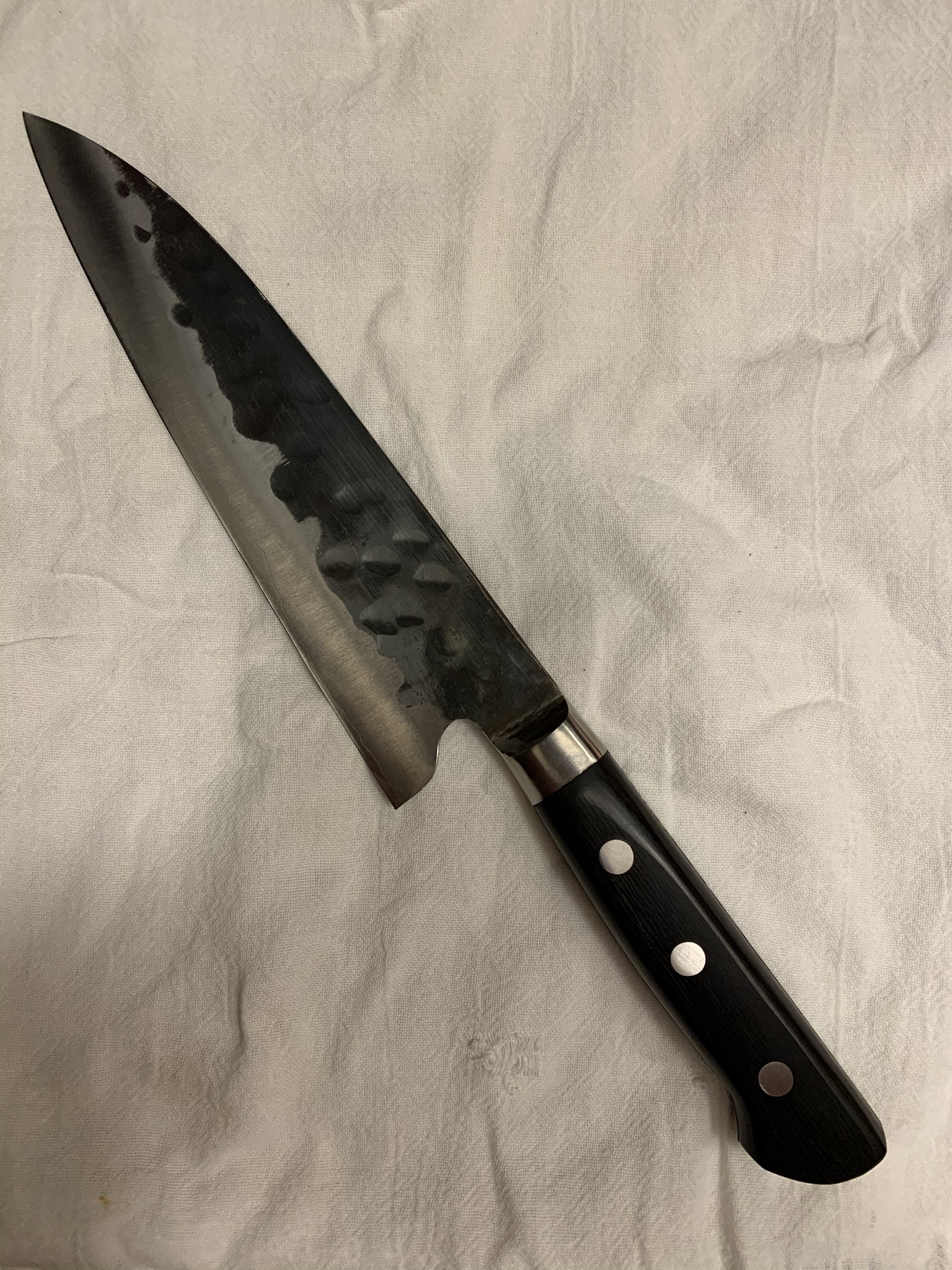

Here is the knife as I received it. Very nice looking knife. The grind was good, just a little uneven in some spots, nothing major at all. The finish on the exposed Jigane was probably 220 grit or so, pretty rough. The lacquer finish was ok. I scrubbed the knife with a worn out green scrubby and the lacquer smoothed out a lot. The handle is rough as others have reported. Doesn’t bother me very much. I might smooth it out, but I’m not sure I care enough to bother with the effort. The finger notch means you really choke up on it in a pinch grip, it makes the knife feel 10mm smaller in your hand. The aesthetic pushes my buttons for sure.

Here I’m thinning a little bit, and evening up the grind. I’m using an extra course diamond plate for this, and checking my work with a sharpie.

This was probably after 3 passes. It wasn’t an insane amount of work as the grind was quite good, I was doing this to make the knife feel like it was mine and just to know it was even throughout. I genuinely don’t think this work needs to be done to this knife out of the box, but I enjoyed the process.

The next two pictures show my progress after about 3 hours, working on the extra course and course diamond stones, and then up to the 500 grit Shapton Glass. I decided to stop here and finish with sand paper. Getting every scratch out with stones is a massive time investment and I’m doing this for fun, not internet points.

Here’s the sandpaper working the finish after thinning. I just cut little strips, folded in thirds, and used my finger. I have done it stones only, once, and I can’t say I see the point, for me. Especially since one sharpening session is all it takes to scuff it up if any grit touches your polished work. I would like to try some finger stones for this work one day.

Back to the stones to put an edge on it. Shapton 500, 1000, 2000, and a strop loaded with green compound.

The finished result. I blew through a fair amount of the kurouchi when I used the sandpaper. It was a trade off between scratch removal and kurouchi preservation. I chose to err on the side of scratch removal. I’m sure it would have been more intact if I had done all of this on the stones, but again, I enjoy this process but 8+ hours of grinding is not my idea of a good time. The finish is by no means perfect, but it works. I will use this knife and really anything more would just get damaged in use. In fact I already scuffed it while I was putting the edge. This is up to 2k sandpaper, then back to 1k. Next time I want to clean up the finish I probably would stop at 800, I liked the matte satin look at that grit.

Here is the choil. The convex is apparent. The grind gets thinner at the tip. I think the overall geometry is very good.

Corradobrit1

Senior Member

- Joined

- May 2, 2015

- Messages

- 6,828

- Reaction score

- 6,876

From Knifewear. Could be old stock they had in inventory.This one purchased in 2019 did.

So the original buyer gave up on the remedial work and you bought it?

nakiriknaifuwaifu

Senior Member

From Knifewear. Could be old stock they had in inventory.

So the original buyer gave up on the remedial work and you bought it?

Good eye. Yes, I am the current owner of that knife. I'm not sure if I bought it from the original owner.

sliceanddicebaby

Well-Known Member

Apparently the boxes were made of actual wood back in the day. This TF box it's literally the most garbage box I've ever held. Low resolution kanji on printer paper cut by a 3 year old and pasted onto the box crooked.

I want another one.

I want another one.

I’m sure TF is looking at you reprobatively from there right now...

sliceanddicebaby

Well-Known Member

I’m sure TF is looking at you reprobatively from there right now...

no worries because this swine can throw pearls back

the 刀工kanji is just a stray stamp that they use to use more often than not back in the days, it has 0 implication on who in the shop made the blade. every now and it floats its way back into the stations in the shop and they use it. having said that, anyone in the shop have been educated and trained fully to forge and HT as well as each other.

no worries because this swine can throw pearls back

Ou-iiink ouink ouink!

Swine will keep the pearls but throw mud back.

The TF master has spoken!the 刀工kanji is just a stray stamp that they use to use more often than not back in the days, it has 0 implication on who in the shop made the blade. every now and it floats its way back into the stations in the shop and they use it. having said that, anyone in the shop have been educated and trained fully to forge and HT as well as each other.