Has my Zhen VG10 gyuto unfairly colored my opinion of the merits of VG10? (not to mention the general VG10 disparagement found on KKF). It's hard to sharpen - my limitations, not the knife's, perhaps - and just kind of 'meh.' Should I give it another chance? Who makes a great petty using VG10?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VG10 discrimination

- Thread starter henkle

- Start date

Help Support Kitchen Knife Forums:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

parbaked

Senior Member

HattoriWho makes a great petty using VG10?

Tanaka

Takamura is pretty good, if you can spent more Ryusen are great too.

McMan

Senior Member

- Joined

- Feb 15, 2018

- Messages

- 2,757

- Reaction score

- 3,392

Is "basic" bad?...I find it that if I am paying $300+ for a knife I want something else than your VG10 steel. Feels too basic.

Have you tried a Ryusen? If not, perhaps it will change your opinion.

AEB-L and Ginsanko are old stainless variants, too. Done well, they can also be excellent IMO.

Last edited:

At the same time Ryusen offers other more exotic steels be it powder metals with higher hrc SG2/ATS314/Hap40Is "basic" bad?...

Have you tried a Ryusen? If not, perhaps it will change your opinion.

AEB-L and Ginsanko are old stainless variants, too. Done well, they can also be excellent IMO.

Jovidah

I'll make you a sponsor offer you can't refuse...

I also got biased against VG-10 by cheap Chinese gargbage heat-treat VG-10 knives. It's a shame, but I think the lower quality stuff is permanently ruining the reputation of the steel, through no fault of the steel itself.

HansCaravan

Well-Known Member

I've only used one knife with VG-10 but it took and held an edge for months. No problem finishing on a King 6K and never had chips in the edge. Sure, it takes longer than my 52100 carbons to sharpen, but c'mon, you get spoiled working carbon steel on the stones. If the knife didn't hold an edge as long as it did then I may have felt differently about VG-10, but my single experience is positive. YMMV.

I've had several VG10 knives and sharpened tons of them for coworkers over the years. I keep a 180 in the drawer at home permanently. Probably the most common Japanese alloy you will see in non sushi pro kitchens. Because it's relatively cheap, tough, thin, bulletproof stainless with long lasting easy to maintain edges. And every retailer carries a decent utilitarian entry grade VG10 line. I don't know about Zhen. But VG10 is excellent knife steel handled correctly. It's not sexy to most folks here, but it is the the true gateway steel to JKnives and one of the best values for dollars to performance available on the market.

I have 2 vg10 knives, and both of them are up to par at least, kurosaki and ryusen. One might be cobalt special, but close enough.

The ryusen is surprisingly good, easy to get sharp but slightly sticky burrs. Well behaved on the stones, agreeable when grinding. Not super hard, probably close to 61? I’ve recently been able to convince my wife to upgrade to this one, and I regularly see her cutting cakes on metal pans and ceramic plates. I’ve been forced to keep quiet as it hasn’t chipped or really even dulled much from the abuse.

The kurosaki is also easy on stones and seems to deburr with less drama. Also decent “ehh it still cuts stuff” retention after losing the initial of-the-stone bite.

I just don’t like stainless steels (pure vanity), but if either maker puts out something killer in only vg10, I would only hesitate slightly. But crappy Chinese vg10? Nahhhh.. as per @Delat, makes for a good wife-knife it seems.

The ryusen is surprisingly good, easy to get sharp but slightly sticky burrs. Well behaved on the stones, agreeable when grinding. Not super hard, probably close to 61? I’ve recently been able to convince my wife to upgrade to this one, and I regularly see her cutting cakes on metal pans and ceramic plates. I’ve been forced to keep quiet as it hasn’t chipped or really even dulled much from the abuse.

The kurosaki is also easy on stones and seems to deburr with less drama. Also decent “ehh it still cuts stuff” retention after losing the initial of-the-stone bite.

I just don’t like stainless steels (pure vanity), but if either maker puts out something killer in only vg10, I would only hesitate slightly. But crappy Chinese vg10? Nahhhh.. as per @Delat, makes for a good wife-knife it seems.

Last edited:

I think VG10 is great for knives that don’t get sharpened very often. We have a JCK Natures petty in VG10 that stands up to abuse (my wife cuts directly on plates with it). It loses the freshly-sharpened edge pretty quickly but stays usefully sharp for ages.

I sharpen it every few months on general principles but always think that I shouldn’t even bother because it’ll go back to that “just a bit dull but sharp enough” feeling almost immediately. I don’t have a VG10 gyuto that I use regularly anymore, so take this with a grain of salt. My Shun gyuto in VG10 microchipped a lot so it’s retired, but the petty has been bulletproof; very likely just a poor heat treat on the Shun.

I sharpen it every few months on general principles but always think that I shouldn’t even bother because it’ll go back to that “just a bit dull but sharp enough” feeling almost immediately. I don’t have a VG10 gyuto that I use regularly anymore, so take this with a grain of salt. My Shun gyuto in VG10 microchipped a lot so it’s retired, but the petty has been bulletproof; very likely just a poor heat treat on the Shun.

ModRQC

Just shutup n' grabbit!

Bad or rapidly failing VG-10 edges are very highly likely incomplete deburring. It's that kind of steel. However once deburred, nothing much to say against it.

Ryusen and Tanaka were in my experience a step above indeed.

Ryusen and Tanaka were in my experience a step above indeed.

- Joined

- Jul 4, 2012

- Messages

- 2,124

- Reaction score

- 4,028

VG-10 is so common that it can seem pedestrian, but it's a darned good knife steel. I don't really have anything against it that I don't have against most stainless steels: that sharpening properly involves a lot more time chasing the burr than it does for carbon steels.

However, this is not true of my Hattori VG-10 petty. I am not sure what sorcery was involved, but this is one VG-10 knife that is a pleasure to sharpen.

However, this is not true of my Hattori VG-10 petty. I am not sure what sorcery was involved, but this is one VG-10 knife that is a pleasure to sharpen.

My Masakage Kumo santoku has a core of VG10 and I have nothing bad to say about it. In a home kitchen, it holds an edge forever and is a pleasure to use. I suspect the skill of the blacksmith (Anryu, in this case) has a lot to do with the quality of VG10 blades. This knife has been on my knife strip since I got it, and like santokus, it is just a handy knife to pull out for a quick job.

Has my Zhen VG10 gyuto unfairly colored my opinion of the merits of VG10? (not to mention the general VG10 disparagement found on KKF). It's hard to sharpen - my limitations, not the knife's, perhaps - and just kind of 'meh.' Should I give it another chance? Who makes a great petty using VG10?

A petty knife? The others have already mentioned Ryusen and Hattori.

If you're open to trad-j knives, then you might also contact a Kikumori dealer about a VG-10 mukimono (they're made by Nakagawa if I remember correctly), or maybe contact Ichimonji Mitsuhide to discuss a short tsurugi-yanagiba in VG-10.

I've owned, used and sharpened a lot of VG10. From pocket knives to chef knives and hardness ranges of probably 58-61. In my opinion, it's an outstanding all around steel. Obtaining keen edges, especially on chunky knives can be a challenge and one that may not be worth the effort, but if fully deburred it will hold it's "working" edge well.

These days I see it largely as a "utility" type steel. Good for those knives that might get some harder use and a little less maintenance but not something I want for a daily driver or finer work.

These days I see it largely as a "utility" type steel. Good for those knives that might get some harder use and a little less maintenance but not something I want for a daily driver or finer work.

Ryusen used to do OEM works for Hattori, at least this is what I read before, so their treatment should be all good. By the way, anyone have experience with both Bontenunryu and Blazen? Are they similar apart from steel and Damascus? If I ever want a nice Western handled stainless gyuto those and Takamura pro would be on my list.

McMan

Senior Member

- Joined

- Feb 15, 2018

- Messages

- 2,757

- Reaction score

- 3,392

Is your opposition to VG-10 based on trying good VG-10 (like Ryusen and Tanaka) and being dissatisfied?At the same time Ryusen offers other more exotic steels be it powder metals with higher hrc SG2/ATS314/Hap40

bahamaroot

Idiot Savant

I have a VG-10 Fujin and have no complaints. Had a Megumi years ago and eventually sold it to a friend. It had excellent performance and help an edge for months in a home environment with just stropping. Kurosaki does a great job with VG-10.

That reminds most Takefu village knives should have pretty good ht of VG10 since they are sponsored by Takefu steel.I have a VG-10 Fujin and have no complaints. Had a Megumi years ago and eventually sold it to a friend. It had excellent performance and help an edge for months in a home environment with just stropping. Kurosaki does a great job with VG-10.

What whetstone grit would you use to sharpen this knife?Takamura VG10 is great.

Last edited:

I'm really happy with my Naniwa Pro 800 and 3000. I do most of my sharpening on them. But it's very personal choice.What whaterstone grit would you use to sharpen this knife?

I have shapton pro 1000 and a 3000 whetstone that I think is manufactured by King.I'm really happy with my Naniwa Pro 800 and 3000. I do most of my sharpening on them. But it's very personal choice.

I have bought this knife some days ago and I wonder what whetstone should I use.

NBrewster

Well-Known Member

- Joined

- Sep 20, 2018

- Messages

- 121

- Reaction score

- 114

I have a suisin vg10 Gyuto they made for an anniversary celebration with Korin in NYC.

I. Love. That. Knife.

It's like a Mercedes S500.

It does everything well. It's no ******** and it never has any problems.

Are there knives that are more interesting/fun? Yes.

But when in doubt I will always reach for the suisin

I. Love. That. Knife.

It's like a Mercedes S500.

It does everything well. It's no ******** and it never has any problems.

Are there knives that are more interesting/fun? Yes.

But when in doubt I will always reach for the suisin

The most-sharpened knife in my kitchen is VG-10, and I don’t mind sharpening it at all. I think it got a bad rap over a decade ago from sloppy factory knives, but that was a correlation/causation mix-up. For kitchen use, it’s pretty darn nice.

The weirdest part to me is the cobalt, which doesn’t seem to help the baseline mechanical properties in any way (doesn’t help edge retention or stainless properties in a meaningful way, lowers toughness). I have a pet theory / wild speculation that the cobalt was added so entry-level users could get knives sharpened by “professionals” with motorized wheels, and the steel would survive a bit of overheating. That way you see edge retention remain after abusive sharpening, and don’t really need stones or water cooling to do it properly. Who the heck knows. Maybe there is/was a surplus that just needed to be used.

https://knifesteelnerds.com/2018/05/14/why-there-is-cobalt-in-vg-10/

The weirdest part to me is the cobalt, which doesn’t seem to help the baseline mechanical properties in any way (doesn’t help edge retention or stainless properties in a meaningful way, lowers toughness). I have a pet theory / wild speculation that the cobalt was added so entry-level users could get knives sharpened by “professionals” with motorized wheels, and the steel would survive a bit of overheating. That way you see edge retention remain after abusive sharpening, and don’t really need stones or water cooling to do it properly. Who the heck knows. Maybe there is/was a surplus that just needed to be used.

https://knifesteelnerds.com/2018/05/14/why-there-is-cobalt-in-vg-10/

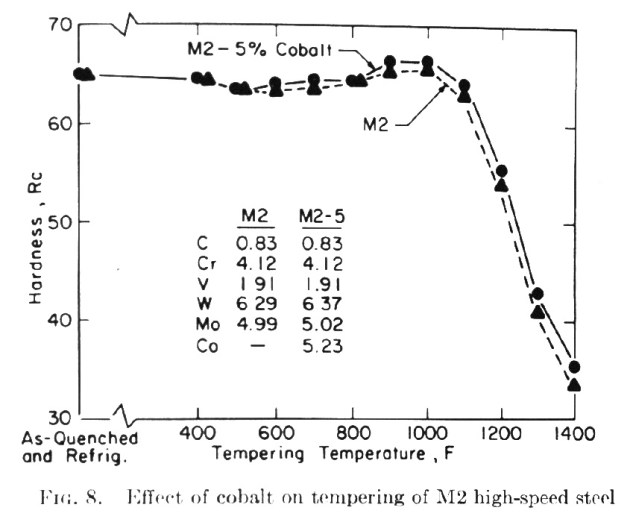

Hot Hardness and Tempering Resistance

Since hot hardness is the main reason a cobalt addition is made to steel, I think it makes sense to start here. An introduction to the mechanisms of tempering can be read here: What Happens During Tempering of Steel? It was found that a cobalt addition led to higher hardness with high tempering temperatures in high speed steels [2]:

The surface coating thing seems pretty plausible to me. Do stainless KU coatings require high temps?The most-sharpened knife in my kitchen is VG-10, and I don’t mind sharpening it at all. I think it got a bad rap over a decade ago from sloppy factory knives, but that was a correlation/causation mix-up. For kitchen use, it’s pretty darn nice.

The weirdest part to me is the cobalt, which doesn’t seem to help the baseline mechanical properties in any way (doesn’t help edge retention or stainless properties in a meaningful way, lowers toughness). I have a pet theory / wild speculation that the cobalt was added so entry-level users could get knives sharpened by “professionals” with motorized wheels, and the steel would survive a bit of overheating. That way you see edge retention remain after abusive sharpening, and don’t really need stones or water cooling to do it properly. Who the heck knows. Maybe there is/was a surplus that just needed to be used.

https://knifesteelnerds.com/2018/05/14/why-there-is-cobalt-in-vg-10/

Bobby2shots

Senior Member

Fake VG-10,,,,

When VG-10 knives first started to appear in JAPAN, they immediately became wildly popular, with sky-rocketing sales. When foreign knife manufacturers saw this, they decided they wanted a piece of that action, and started selling cheaply-made knives that had a VG-10 Logo on the box,,,, they didn't say "made with" or, "made from" VG-10 steel,,,, they just printed that VG-10 logo prominently on the packaging, so it was legal. This apparently led to varying opinions about "VG-10" knives. To further confuse consumers, they even stopped labeling the country of manufacture origin. (Made in China, India, or Viet-Nam, etc."

If the packaging states "VG-10 steel" and Made in Japan" it's probably legit. If it just states "VG-10",,, and especially if no country of origin is indicated on the knife, or on the box,,,, buyer beware.

When VG-10 knives first started to appear in JAPAN, they immediately became wildly popular, with sky-rocketing sales. When foreign knife manufacturers saw this, they decided they wanted a piece of that action, and started selling cheaply-made knives that had a VG-10 Logo on the box,,,, they didn't say "made with" or, "made from" VG-10 steel,,,, they just printed that VG-10 logo prominently on the packaging, so it was legal. This apparently led to varying opinions about "VG-10" knives. To further confuse consumers, they even stopped labeling the country of manufacture origin. (Made in China, India, or Viet-Nam, etc."

If the packaging states "VG-10 steel" and Made in Japan" it's probably legit. If it just states "VG-10",,, and especially if no country of origin is indicated on the knife, or on the box,,,, buyer beware.

I think even a lot of knives that say Japanese VG10 steel have questionable heat treats. Could also just be an outright or technical lie (complies to VG10 "spec" even though it really isn't a spec)