jessf

Senior Member

- Joined

- Jan 10, 2016

- Messages

- 869

- Reaction score

- 6

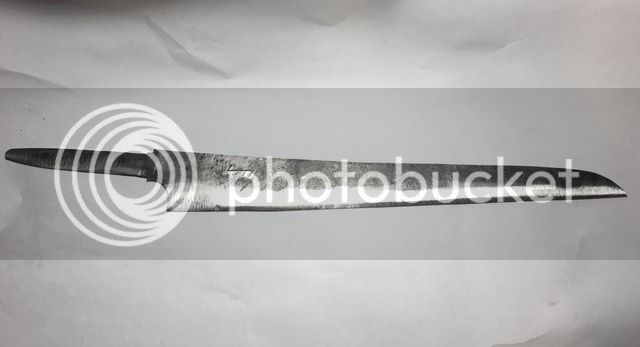

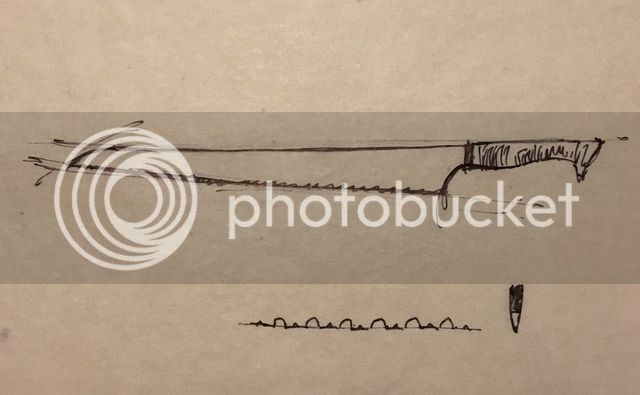

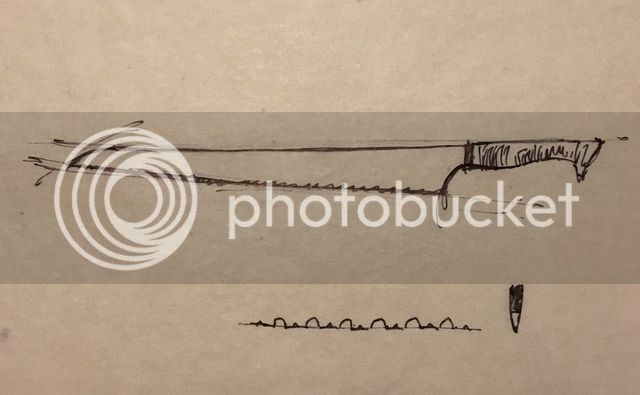

Ive got it in my head that a bread knife is the next project. I have some 1095 left so i want to see if my ideas work. I'll share a concept sketch first.

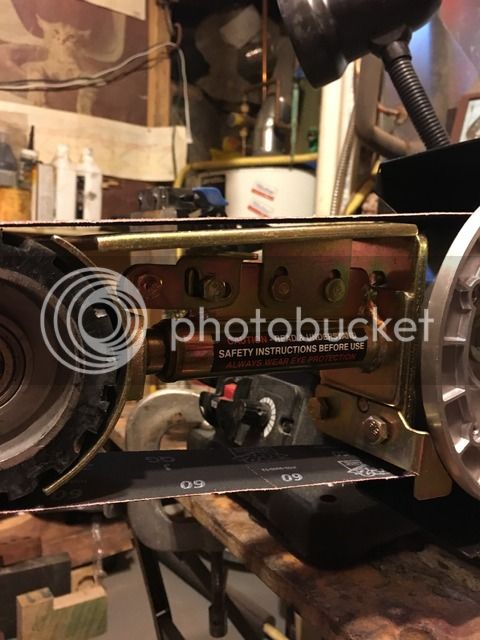

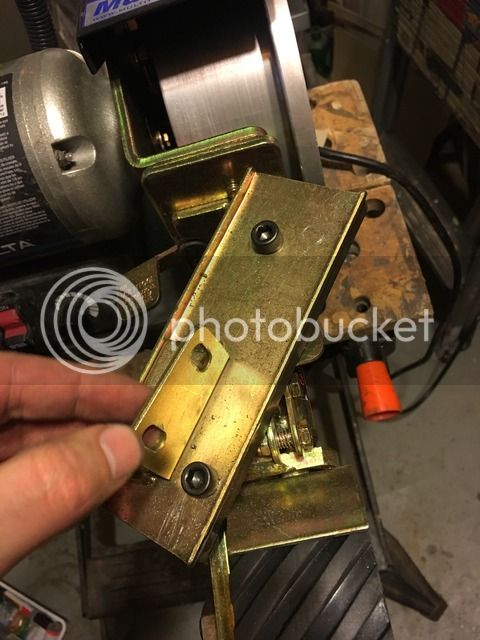

Ill need to forge out the length and cross section then file in the teeth before heat treat. I picked up a 38x38x600 piece of curly maple that I'll stain/dye. I also have the last piece of mokume left over from the Not a Gyuto project. The larger piece went to the paring knife.

Ill need to forge out the length and cross section then file in the teeth before heat treat. I picked up a 38x38x600 piece of curly maple that I'll stain/dye. I also have the last piece of mokume left over from the Not a Gyuto project. The larger piece went to the paring knife.