jessf

Senior Member

- Joined

- Jan 10, 2016

- Messages

- 869

- Reaction score

- 6

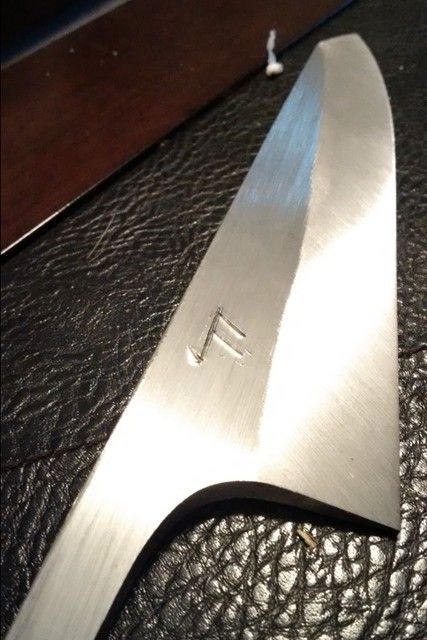

I called my local steel supplier and they had A2 and D2 steel in stock. So I thought about it and did a little research and decided that the D2 would be as good a place to start. It's used for tool and die, planer blades being a common use. I figure the best knife geometry and grind for this type of steel with large carbides might be a thick, single bevel honesuki as that most closely resembles a planer blade.

Steel is D2 1/4"x2"x24"

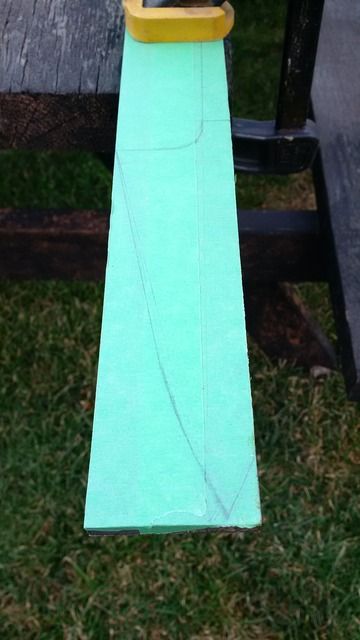

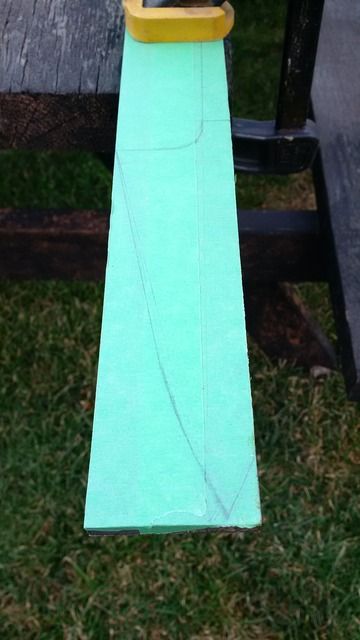

Blade specs will be:

-165mm choil to tip

-45mm at the heal

Nothing fancy, just a grinder, painters mask, safety squints, ear protection, gloves a few clamps and falling snow.

I used a scrap piece of steel as a straight edge with great effect.

this pile of garbage crapped out half way through. Smoked the motor, might be the brushes or windings or some other factory defect. Either way it was a gift from two years ago and I don't recall registering the warranty. Luckily I have two grinders and was able to finish the job.:wink:

A little cleanup on the belt sander. I need to work the radius on the choil area because right now the blade tapers too much where the tang would enter the handle. From what I've seen, the spine and the front side of the tang area are parallel lines as they enter the handle.

got the backside flat, I will need to hollow grind this later, for now it can remain flat.

Call this a rough blank and my task done for the night. On Wednesday I'll take the grinder to it again and begin thinning it out.

Steel is D2 1/4"x2"x24"

Blade specs will be:

-165mm choil to tip

-45mm at the heal

Nothing fancy, just a grinder, painters mask, safety squints, ear protection, gloves a few clamps and falling snow.

I used a scrap piece of steel as a straight edge with great effect.

this pile of garbage crapped out half way through. Smoked the motor, might be the brushes or windings or some other factory defect. Either way it was a gift from two years ago and I don't recall registering the warranty. Luckily I have two grinders and was able to finish the job.:wink:

A little cleanup on the belt sander. I need to work the radius on the choil area because right now the blade tapers too much where the tang would enter the handle. From what I've seen, the spine and the front side of the tang area are parallel lines as they enter the handle.

got the backside flat, I will need to hollow grind this later, for now it can remain flat.

Call this a rough blank and my task done for the night. On Wednesday I'll take the grinder to it again and begin thinning it out.