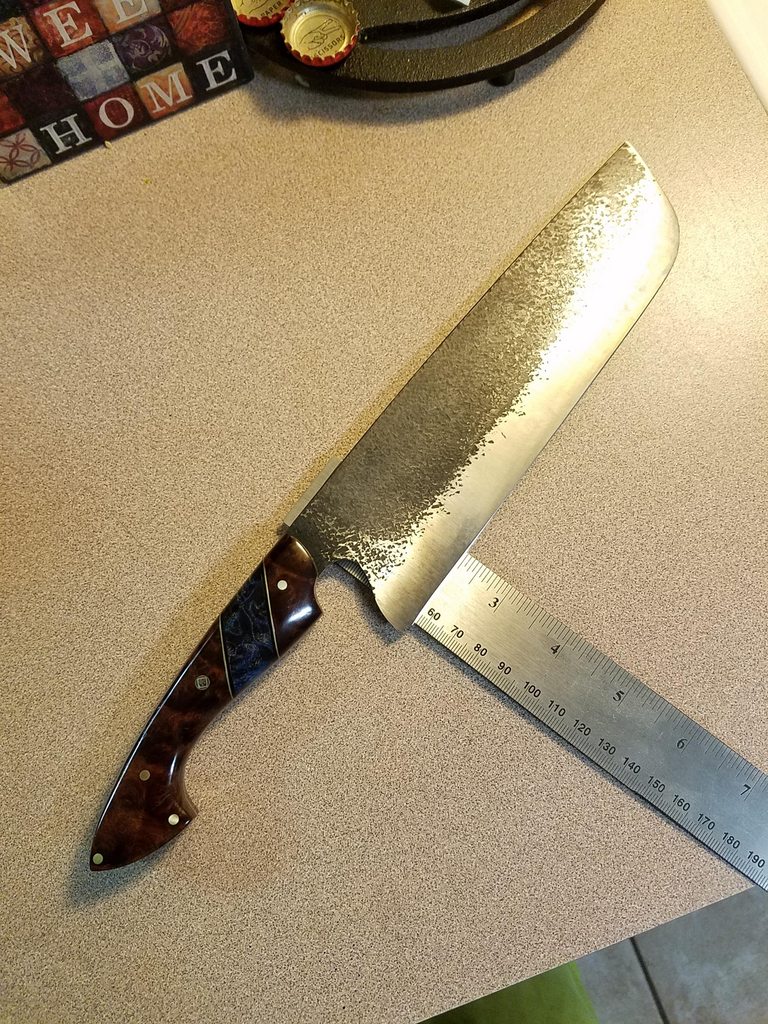

I'm a (very) small time knife maker (so far 4 knives) and am finalizing my first Nakiri, 150mm san mai wought Iron/C125.

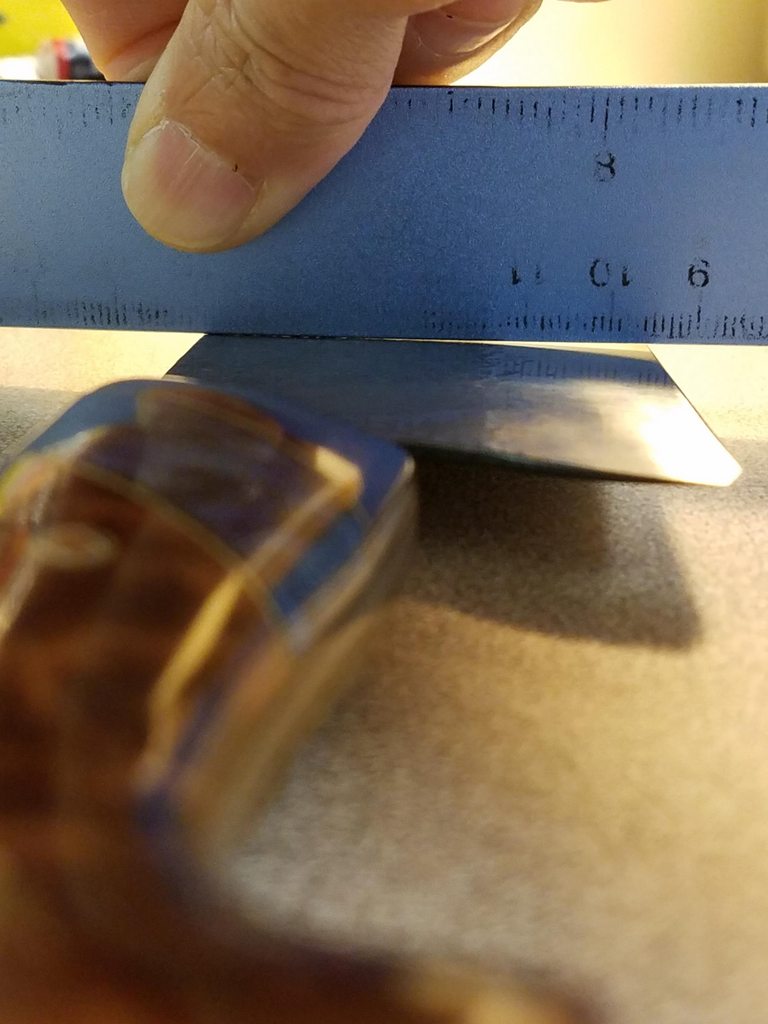

Hight: 52mm

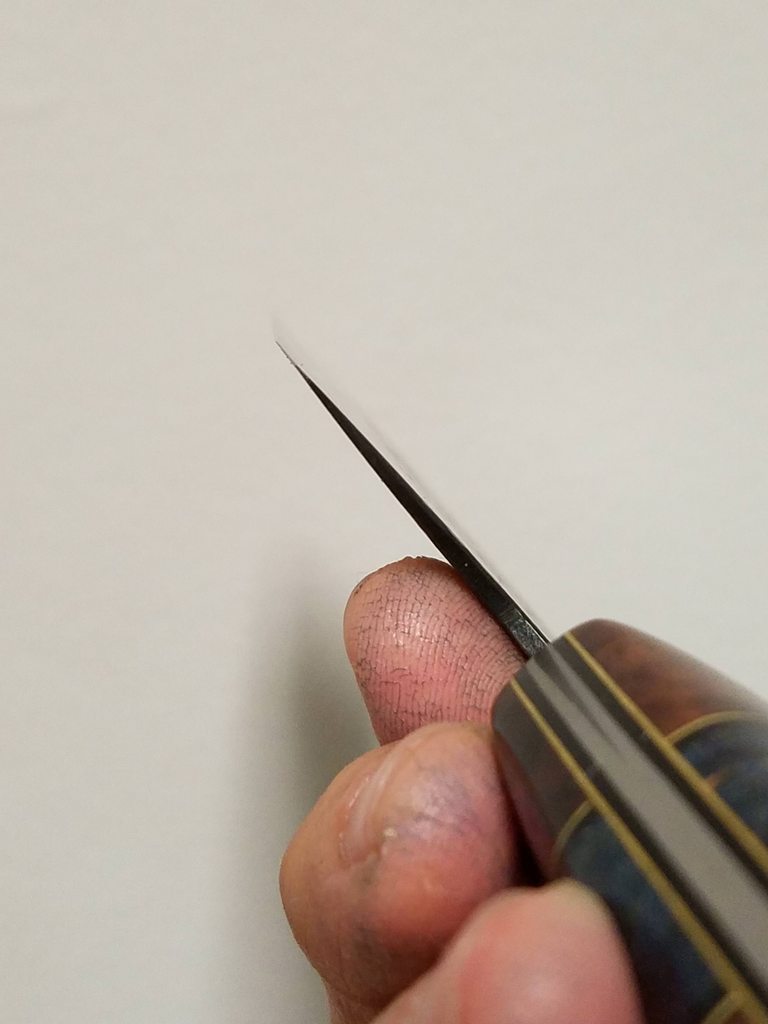

Width above heel 4.5 mm

Width 1 cm from tip: 1.5 mm

(Thanks to Zweber12 for your great site and data: http://kitaeji.com/index.html)

I also have a good idea as to the grind from Kippington, 'A Basic Explanation of Asymmetry', https://www.kitchenknifeforums.com/...of-asymmetry.33951/?highlight=asymetric+grind

What I am still missing is the grind of the 'Flats' of the Nakiri.

I plan on a 70/30 bevel grind, but what about the rest of the 'Flats'. its so thin, there is hardly any place for Convex, S grinds or anything else, so how do you avoid stickatge with such a large flat?

Appreciate your inputs.

Love this forum!

Hight: 52mm

Width above heel 4.5 mm

Width 1 cm from tip: 1.5 mm

(Thanks to Zweber12 for your great site and data: http://kitaeji.com/index.html)

I also have a good idea as to the grind from Kippington, 'A Basic Explanation of Asymmetry', https://www.kitchenknifeforums.com/...of-asymmetry.33951/?highlight=asymetric+grind

What I am still missing is the grind of the 'Flats' of the Nakiri.

I plan on a 70/30 bevel grind, but what about the rest of the 'Flats'. its so thin, there is hardly any place for Convex, S grinds or anything else, so how do you avoid stickatge with such a large flat?

Appreciate your inputs.

Love this forum!