WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

Well the workshop was unusually tidy for a monday morning, so I thought I would get some pictures My humble workshop is on an industrial estate in Hereford. I've not been in this workshop more than a year but have been on this site for about ten years. I moved not to long ago from a big breezy leaky tin tunnel not 200 yards away. It was still an effort to move:running: This one is a bit smaller, but its waterproof, which is a real luxury

My humble workshop is on an industrial estate in Hereford. I've not been in this workshop more than a year but have been on this site for about ten years. I moved not to long ago from a big breezy leaky tin tunnel not 200 yards away. It was still an effort to move:running: This one is a bit smaller, but its waterproof, which is a real luxury I work on my own for the larger part, with the help of my machines. I regularly have work experience students come and help though, especially If I have a larger scale project on.

I work on my own for the larger part, with the help of my machines. I regularly have work experience students come and help though, especially If I have a larger scale project on.

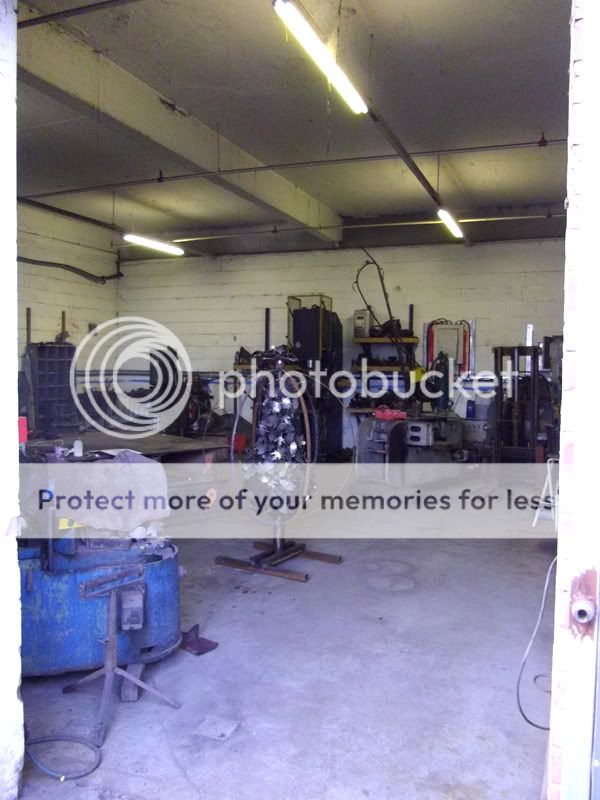

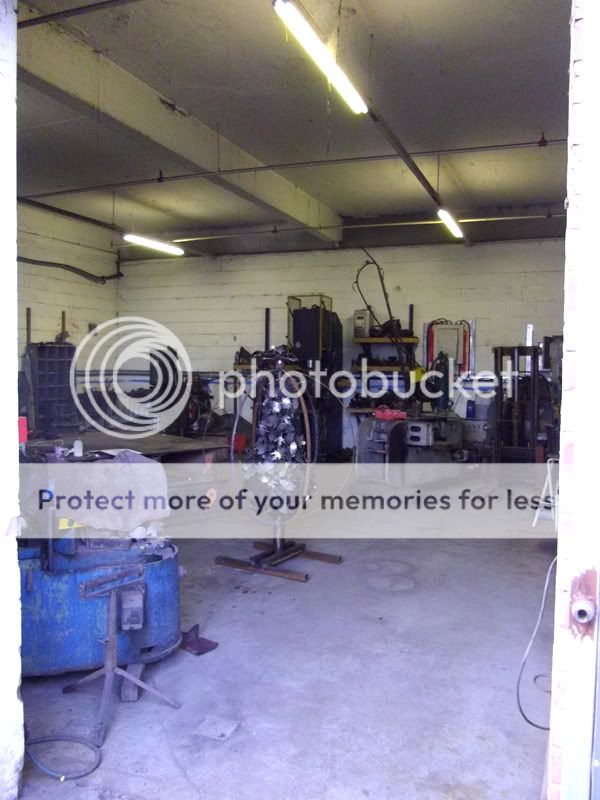

Through the shutter door.

My work table in the middle there, overbuilt of course, but you never know what you'll have to build on it.

Couple of new additions, most of my tools are pretty old. But these work fine.

My good old Donkey Saw, in need of the belts changing at the moment.

Grinding bench

This big boy saves me allot of heat on larger projects. 100 ton horizontal press, would have been used for cold curving railway track originally.

Vertical forging press and various tooling

My little trusty Anyang 40K:biggrin:

Loads of tools, I could do with making a load more tongs, but I've been saying that for years. As i'm mostly on my own I use allot of spring tools on a tool holder.

Through the shutter door.

My work table in the middle there, overbuilt of course, but you never know what you'll have to build on it.

Couple of new additions, most of my tools are pretty old. But these work fine.

My good old Donkey Saw, in need of the belts changing at the moment.

Grinding bench

This big boy saves me allot of heat on larger projects. 100 ton horizontal press, would have been used for cold curving railway track originally.

Vertical forging press and various tooling

My little trusty Anyang 40K:biggrin:

Loads of tools, I could do with making a load more tongs, but I've been saying that for years. As i'm mostly on my own I use allot of spring tools on a tool holder.