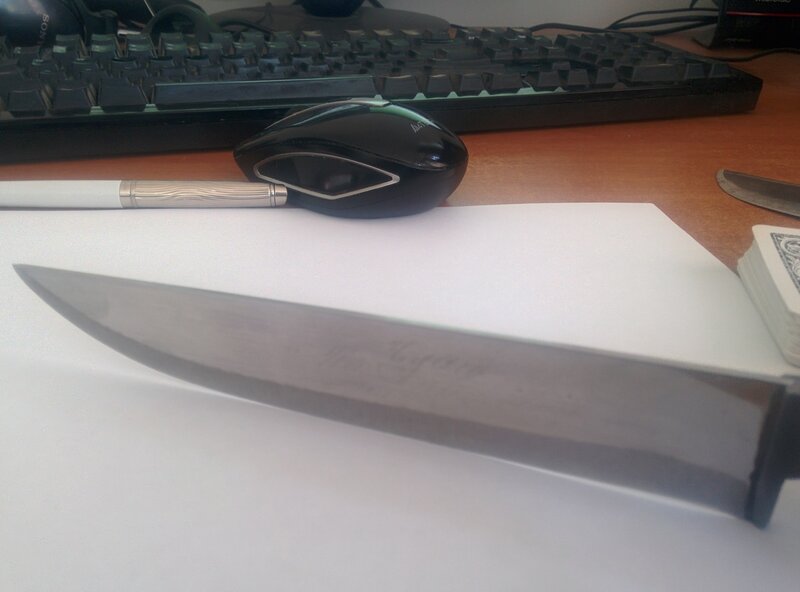

I am new to freehand sharpening, waiting now for my newly ordered stones to arrive. Have a couple of knives pictured below that had been sort of screwed up by 'professional' sharpeners. I need the edge to be in a straight line starting at the bolster all the way to where the curve to tip starts so that there is no gap between the edge and the cutting board.

What is the right approach and technique to do this with whetstones?

Any advise shall be appreciated.

What is the right approach and technique to do this with whetstones?

Any advise shall be appreciated.