GaryWGraley

Member

- Joined

- Feb 12, 2015

- Messages

- 13

- Reaction score

- 2

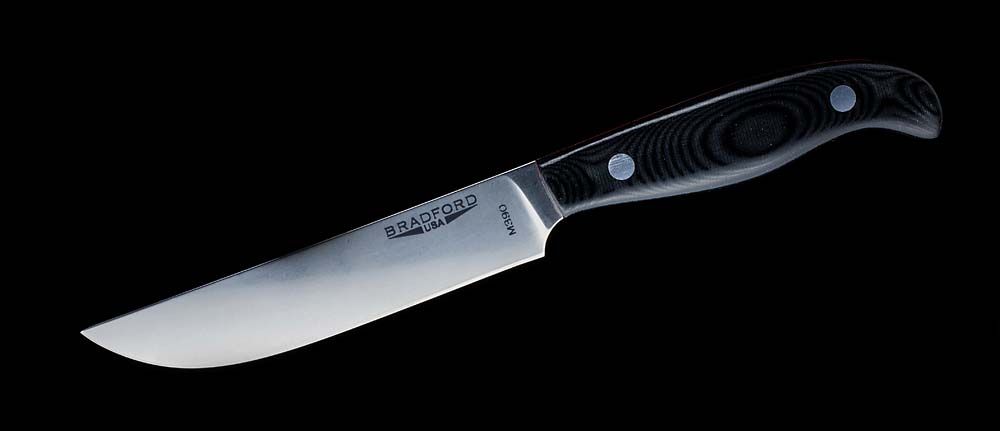

Hi folks, while I'm not quite up to the higher end kitchen cutlery, yet, I was gifted this knife that I really like, it's more of a steak knife and not so much food prep, but I'm sure it could be pressed into that type of service.

This is made by a relatively new kid on the block out of Renton Washington, near Seattle, Bradford Larkin, he is setup as Bradford USA, you can google to find him if you are interested, since he's not a member here that I know of, I won't put links to his place.

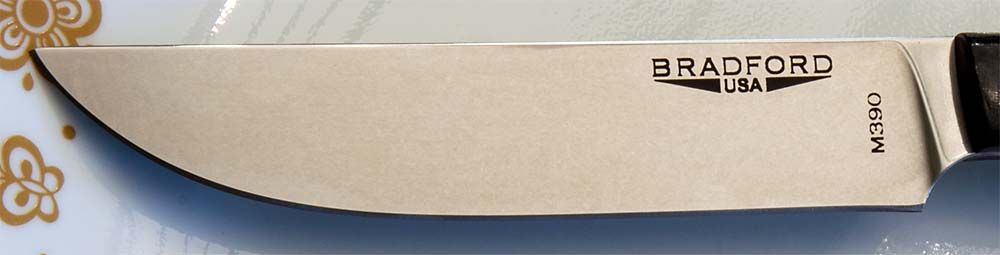

But, this is called the Gatsby, nicely made and using some high tech powdered metal steel, M390 and cuts very very well too !

The blade has about 2.7mm thick at the spine and measures about 4.6" long from tip to handle.

The handle is nicely contoured as well, the micarta is polished but when wet it does provide a good tacky grip, as I noticed when I washed it all down on arrival.

for reference, the plate is about 10 1/4" diameter

Not one to leave things alone, just ask my wife I wasn't that fond of the high point, I prefer a little lower point, one that is, well, pointier as it were, so I took some gaffers tape and laid it on the blade to see what it might look like with some metal removed.

I wasn't that fond of the high point, I prefer a little lower point, one that is, well, pointier as it were, so I took some gaffers tape and laid it on the blade to see what it might look like with some metal removed.

The clip starts just about mid point of the blade, giving it a nice long clip point to it, bringing the tip about in line with those corby bolts too. I had emailed Bradford, worried it would upset him to see such a travesty but he replied that he liked it and also likes that folks will take the time to do things on their own to make the knife their own, I was relieved to get that email reply here's a shot of the knife in it's new ground way, let me tell you that m390 is some tough stuff to grind, especially once hardened! I'm not really setup for metal working, just have a make shift disk sander 9", it wore down the new pad of 100 grit paper kinda fast. I took my time doing this, used a magic marker to make a reference line to work with and dipped the blade frequently to keep cool.

here's a shot of the knife in it's new ground way, let me tell you that m390 is some tough stuff to grind, especially once hardened! I'm not really setup for metal working, just have a make shift disk sander 9", it wore down the new pad of 100 grit paper kinda fast. I took my time doing this, used a magic marker to make a reference line to work with and dipped the blade frequently to keep cool.

Pre mod look of the blade;

and one after the mod

I have the kydex sheath which retains this rascal exceedingly well, so it could even be carried neck wise without any worry of it coming free and being light it would work well in that roll.

SO, I now have a quite sharp and very pointy fancy steak knife, with the curve there you can still use this for that very task if you so desire and it ended up not making the blade much shorter at all.

And I hear tell that Brad is in the works of making a Chef's knife too, not sure when that might be ready.

He also makes some more camp style or hunting knives too in his Guardian series, those have screwed on handles of G10 that are very grippy, but, they are not so much kitchen type knives per se, but of course, you can press those into kitchen duty pretty easily too

G2

This is made by a relatively new kid on the block out of Renton Washington, near Seattle, Bradford Larkin, he is setup as Bradford USA, you can google to find him if you are interested, since he's not a member here that I know of, I won't put links to his place.

But, this is called the Gatsby, nicely made and using some high tech powdered metal steel, M390 and cuts very very well too !

The blade has about 2.7mm thick at the spine and measures about 4.6" long from tip to handle.

The handle is nicely contoured as well, the micarta is polished but when wet it does provide a good tacky grip, as I noticed when I washed it all down on arrival.

for reference, the plate is about 10 1/4" diameter

Not one to leave things alone, just ask my wife

The clip starts just about mid point of the blade, giving it a nice long clip point to it, bringing the tip about in line with those corby bolts too. I had emailed Bradford, worried it would upset him to see such a travesty but he replied that he liked it and also likes that folks will take the time to do things on their own to make the knife their own, I was relieved to get that email reply

Pre mod look of the blade;

and one after the mod

I have the kydex sheath which retains this rascal exceedingly well, so it could even be carried neck wise without any worry of it coming free and being light it would work well in that roll.

SO, I now have a quite sharp and very pointy fancy steak knife, with the curve there you can still use this for that very task if you so desire and it ended up not making the blade much shorter at all.

And I hear tell that Brad is in the works of making a Chef's knife too, not sure when that might be ready.

He also makes some more camp style or hunting knives too in his Guardian series, those have screwed on handles of G10 that are very grippy, but, they are not so much kitchen type knives per se, but of course, you can press those into kitchen duty pretty easily too

G2