Hello All, some updates on the standard mono lines. I will continue to do some as premium, with premium handle materials and some as Utility line with simpler handle materials. Blades will be the same for each line.

Im always tweaking my process and some key evolutions of the finishing process I will share here and it will help you in techniques to keep these knives as thin as they deserbve to be kept at the edge, not only that but maintain the all important convexity.

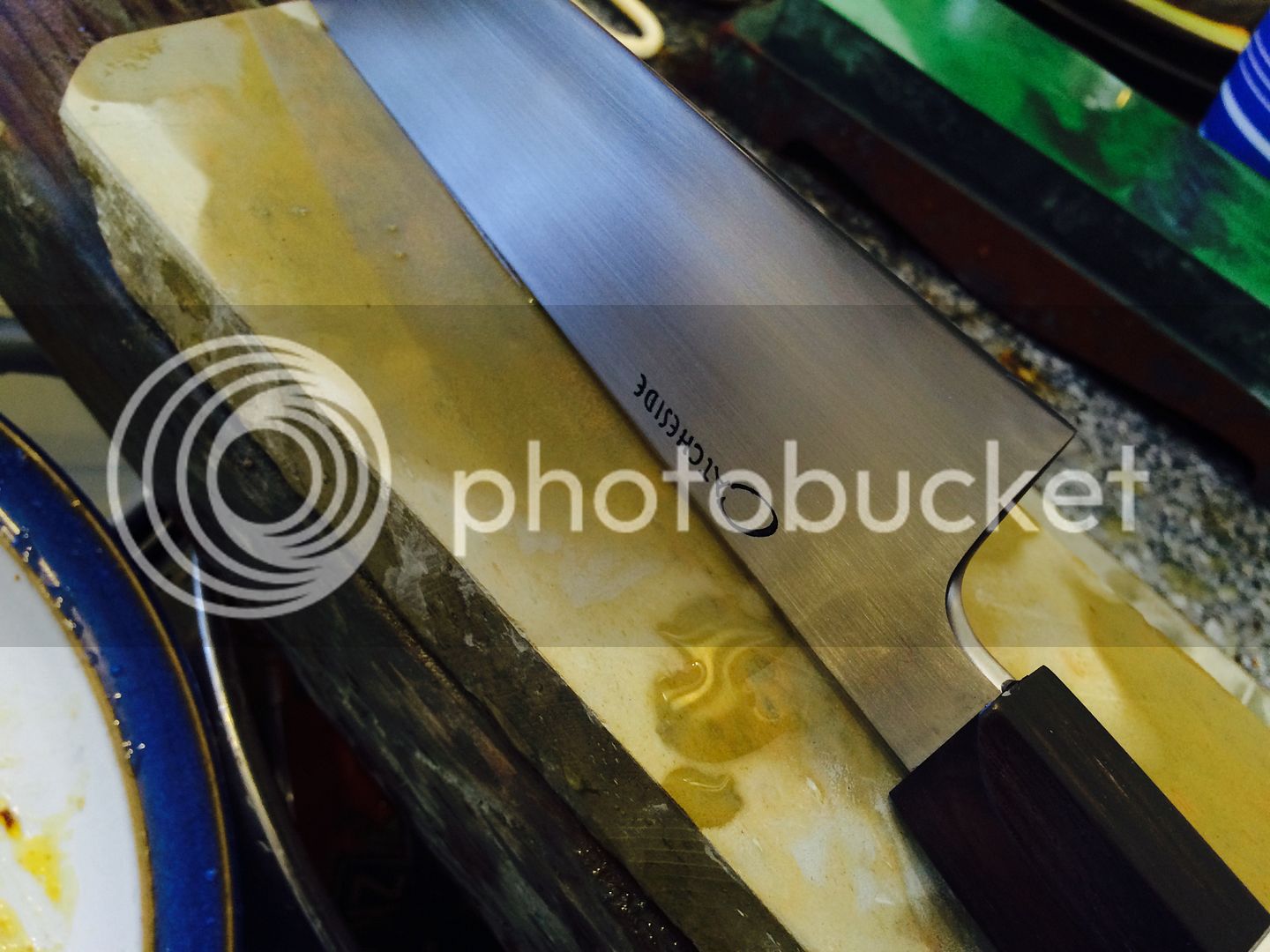

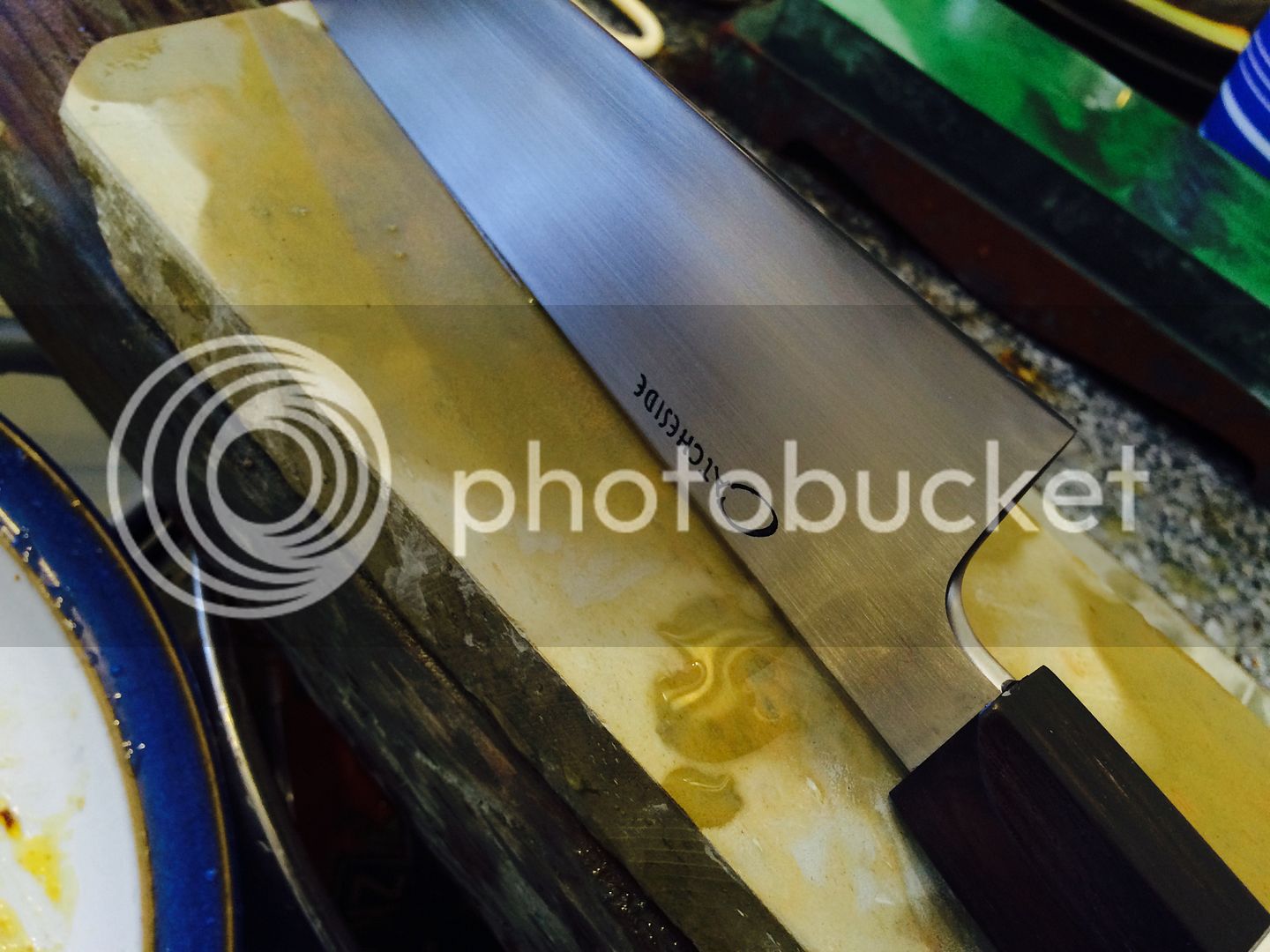

Here is one after grinding, its been down to 150 grit, then a bevel set several times with more thinning in-between on the belt. When the edge is even and thin enough that it flexes at the very edge good to continue to hand finishing.

The first step is to go across the grain on the edge. I use an em 180 grit stone, these are a ceramic based small stone usually silicon carbide abrasive in a ceramic binder. Good quality ones have a nice binding material cut very flat and quickly whilst making a slight slurry.

I never use paper abrasives near the edge of the knife, it can create and follow ripples stones cut flat and true and give you an even bevel. The geometry at the lower bevel is made up of two angles blended, known as a compound bevel, its essential to the cutting performance to keep this blend of convexity and thinness at the very edge. The easiest way to do this is to think of the bevel as the upper and lower portion thin into the lower and blend into the upper, like on single bevel knives.

This gives you a vague idea of the overall geometry everything thinning evenly from here in proportion to the spine.

After the 180 grit edm stone I use something around 800 grit, to finish just the lower bevel, almost sharpening into the edge.

When this is complete I finish with paper abrasives to 400 grit but never on the lower of the lower bevel only blending to about halfway down it. I touch up the edge portion again after with an 800 grit stone, all heel to toe direction at this stage.

When the knife is all finished and handled I hit the stones with it at home. Only a 1000 grit stone is necessary to thin the final part, and always blend into the angle above. My final stone for the edge and the blending is my Takashima, its very forgiving to use for this type of subtle blending. Im now using the stone in the traditional direction as you would usually sharpen.

This is how I can achieve such consistency now in these and how I get them to cut so nicely. You can try this technique on your own knives, I hope it helps

All 2016 Catcheside monos will come stone ready like this.

Here is the first one for 2016, also with the new Heat treatment allowing a very nice edge stable 64hrc

You can find it in my Shop on my site now