- Joined

- Feb 1, 2017

- Messages

- 2,486

- Reaction score

- 3,712

😍😍

Looks great 😀 awesome work. But tone that mirror down to just a nice medium to high grit usuable finish 😀

Welcome to our world... haha.Since malex mentioned it, another down under wood source for some nice stuff at good prices is thetimberjoint.com (he also has some instagram specials). Crazy good prices on ringed gidgee and other beautiful Aussie woods. I just ordered some lace sheoak that were a great deal even though international shipping to me in the US was almost 75% of the price of the wood!

I was thinking the same thingWelcome to our world... haha.

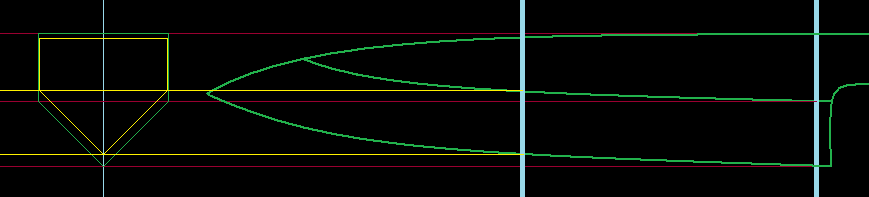

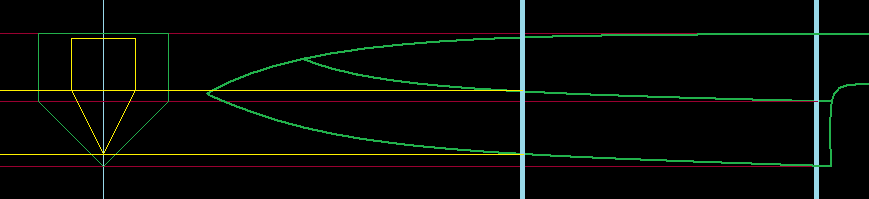

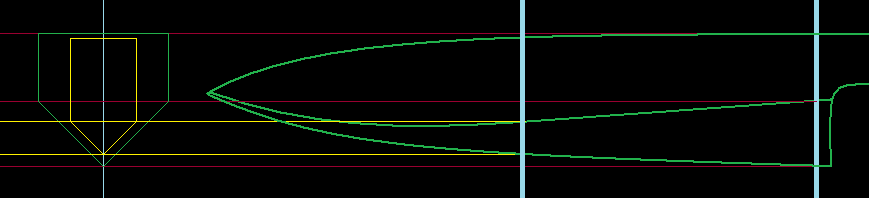

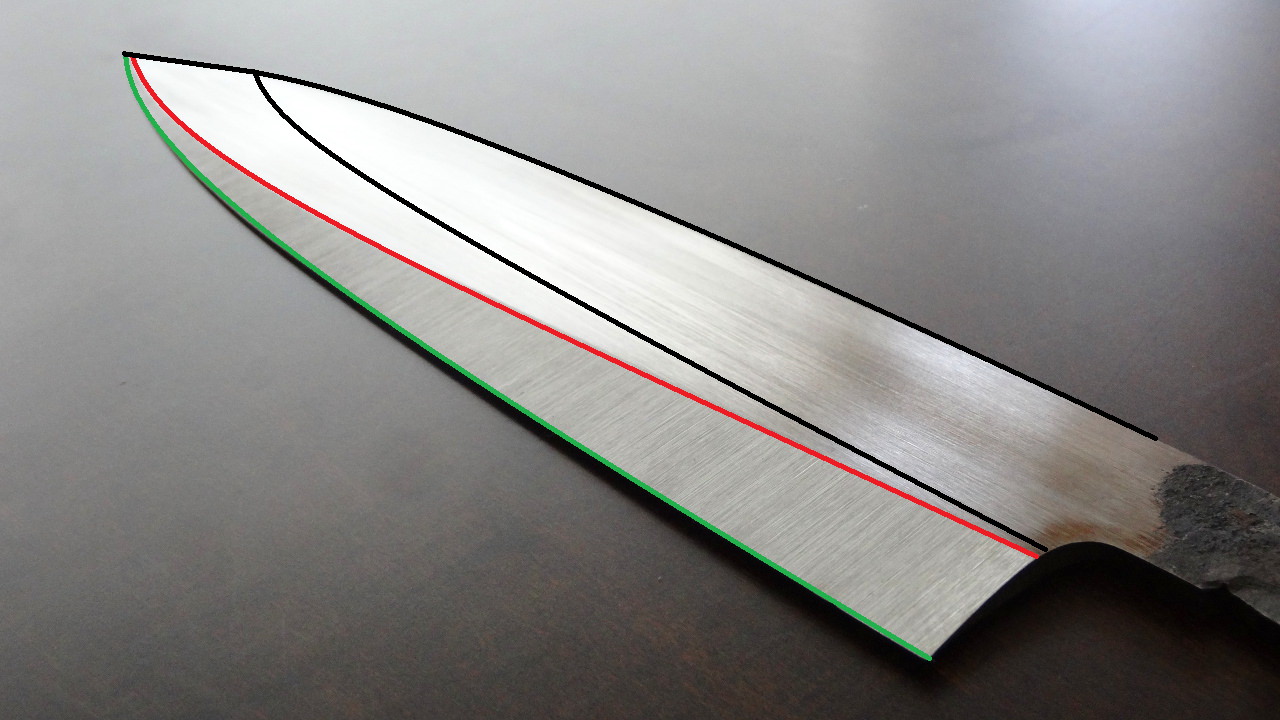

With paying zero homage to actual geometry, I think the shrinking edge grind and the distal taper will cancel one another out. ???

Not trying to ruffle feathers, I just like a thin, thin tip, and it seems this grind leaves a bit of meat behind the shallow grind at the tip. Maybe the heavy distal taper makes the tip thin enough on it's own. Guess it's hard to judge without actually having it on a board...if you need my address...

This knife was waiting for me when I arrived home from work this evening. Havent used it yet but I will definitely put it to use over the next 3 days because Im working 3 doubles in a row.

Im really conflicted as to how I should describe my initial impressions. Part of me wants to downplay how great this knife appears ootb in all the areas that matter and the other part of me doesnt want to hype kippingtons work only so I can keep this guy all to myself for future work.

Initially I was thinking US pass around for this blade but now that seems hard to fathom as the grind really is quite thin and quite frankly I dont think Ill be in the mood to be without it(sorry kippington). No chop, if youre still curious about this knife PM me.

Imagine a filing jig with a not too long file. If the knife is clamped in only once, you get the steepest angle and the smallest bevel in the middle. Closer to the ends of the knife the file has a longer stroke and the bevel angle gets smaller, bevel grows wider.

Initially I was thinking US pass around for this blade but now that seems hard to fathom as the grind really is quite thin and frankly I dont think Ill be in the mood to be without it(sorry kippington).

I believe you're referring to a common misconception about filing/sharpening jigs.

This statement is incorrect:

If you are talking about the increasing distance between the pivot and the file/bevel contact point, the angle stays consistent regardless of that length.

The belly of the knife will cause a change in angle, but if you are working on the flat of the knife there won't be a steeper angle or smaller bevel in the middle. It's just a little trick that your mind is playing on you.

Regardless, neither myself nor Kato use this kind of jig.

Thats all good, I totally understand why you wouldn't want anyone to touch a knife that's thin behind the edge. So many things can go wrong!

Looking forward to your thoughts!

Enter your email address to join: