Justin0505

Founding Member

- Joined

- Feb 28, 2011

- Messages

- 1,454

- Reaction score

- 5

Looks great! How many cycles waa that? Hows the reactivity?

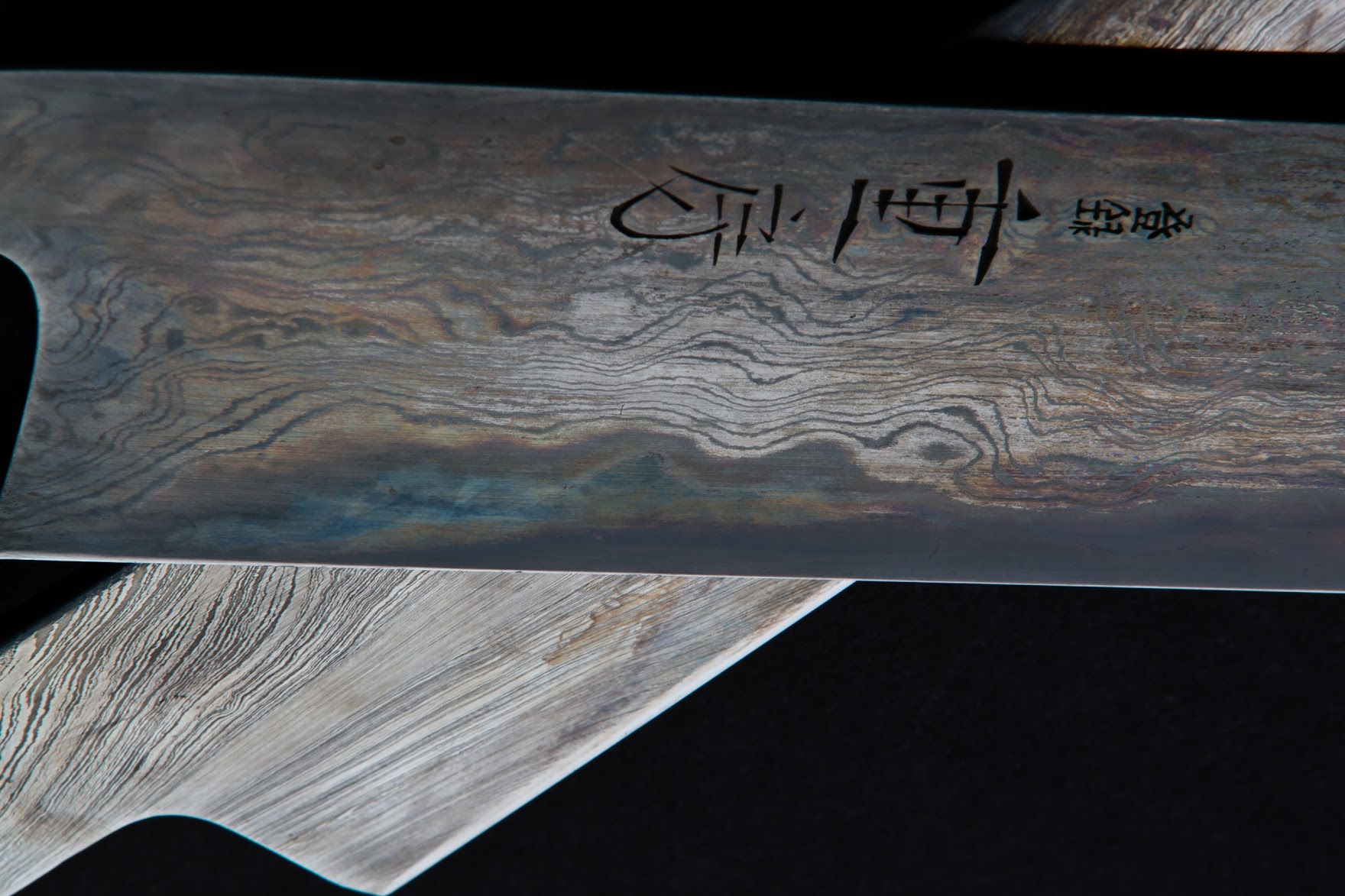

I don't have any pics of the new nakiri yet, but here's my old gyuto that was done with the circuit board etchant

The etching solution creates much greater contrast between the metals, where the hot vinegar leaves a less obvious, more natural look that's closer to the contrast created by the polish that the shigs come with.

Neither the hot vinegar nor the etching acid impart any color. The color down near the edge you see in the pics came from where the etched layer was thinned due to sharpening and thinning and a natural patina took root. The etched metal is still just slightly reactive and it will take on some colors over time, just much, much slower than un-etched.

I might have misread that post, but I thought it was done with etching solution rather than with vinegar.

did you wash the black stuff off and that's the end result? or did you leave that on to make it all badass looking like that?

That's totally awesome. How many times did you do the vinegar bath?

Yes, the shig was done with the PCB etchant, but it also had a light patina that developed OVER the etch.

Hot vinegar yields lower contrast, but a more "natural" look. The process takes a bit longer and obviously is very dependant on the reactivity of the steel (dont think it would work on stainless or very well on semi stainless). I just thinned and then re-etched the kitaeji nakiri that had the vinegar patina on it with PCB etchant and forgot to take pics of the vinegar finish before. Once it gets some more wear and needs another refinishing, I'll try to remember to switch back to hot vinegar and photo-document this time.

Really though, finishes on steel are VERY difficult to capture accurately in a photo and the finish is going to be different depending on the steel in your particular knife and how many cycles you do and for how long, what your level of polish was pre-etch, etc...

The best way to know what your knife is going to look like is just to try it yourself. You're not going to damage your blade (unless you fall asleep).

Enter your email address to join: