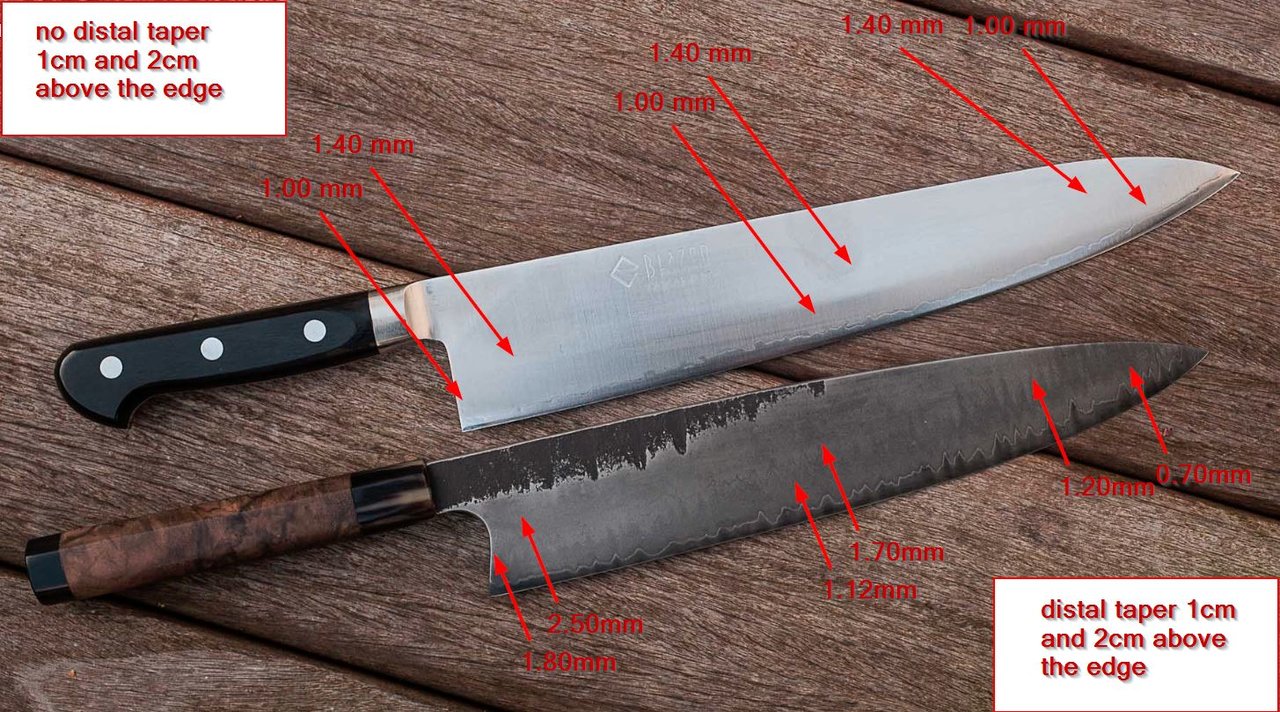

What are the advantages/disadvantages

eg of having a no-taper, no variation grind?

I'm not sure, are you including spinal taper to this?

No variation grinds have a more consistent feel and are less likely to wedge during push cuts.

______________________

Alright, time to add to the confusion with one of the bonus parts.

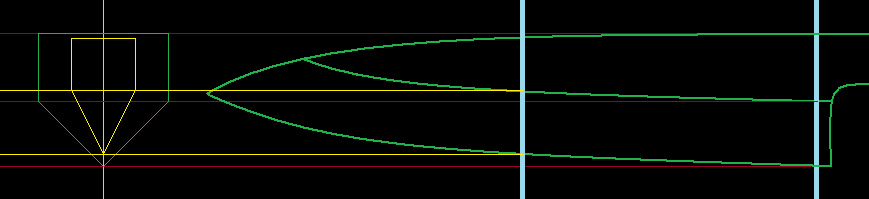

Distal Taper and it's effect on an Asymmetrical grind

As many of us already know, there can be advantages to grinding a knife off-centre.

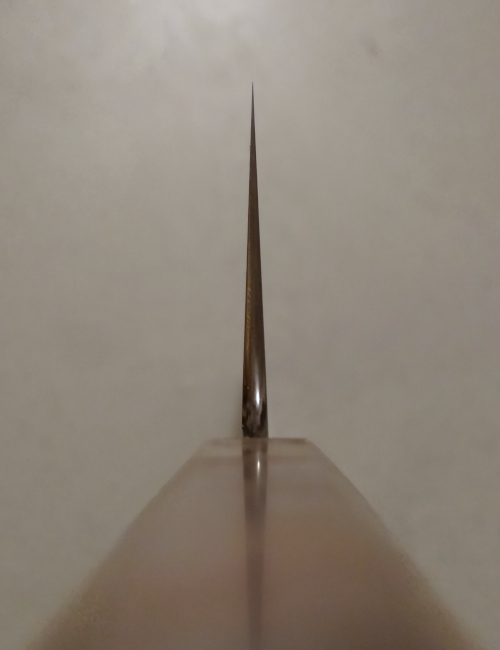

It's a simple enough concept, but what happens when we add distal taper to the mix?

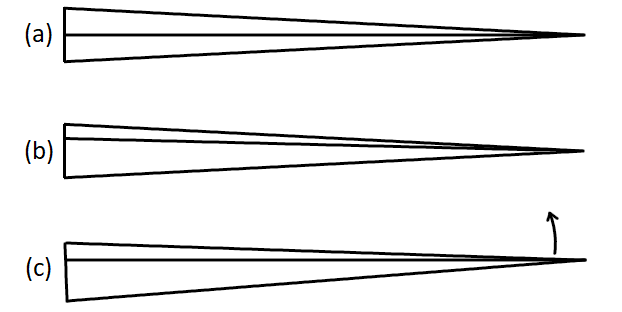

The following triangles represent the spine of a tapered knife, with the middle line going through them representing the cutting edge.

As we know, the cutting edge has to be straight. That's easy enough to do if it runs down the centre of the knife, (a) being an example of that.

Lets look at an asymmetric grind on the knife (b). To maintain a constant ratio of space on the left and right of the edge, we end up with the edge no longer running at the same angle as before.

To have the cutting edge of a tapered knife to run parallel to the handle, the tip of the knife needs to point slightly left or right (c), depending on which bias the knife was designed for.

This is one of the stranger things I've noticed while making tapered knives.