WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

Finally got these two feather billets drawn out and well on the way.

After forging and trimming the profiles.

Andrey - 240 mm Gyuto

Ben - 220mm Gyuto

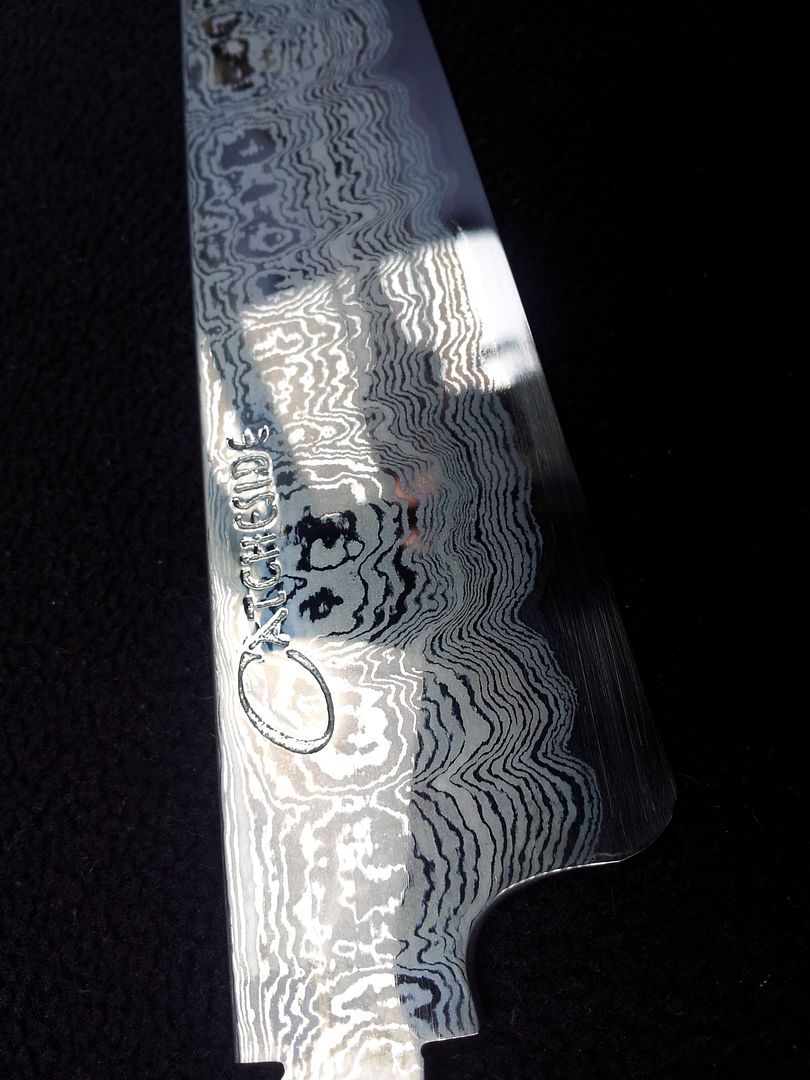

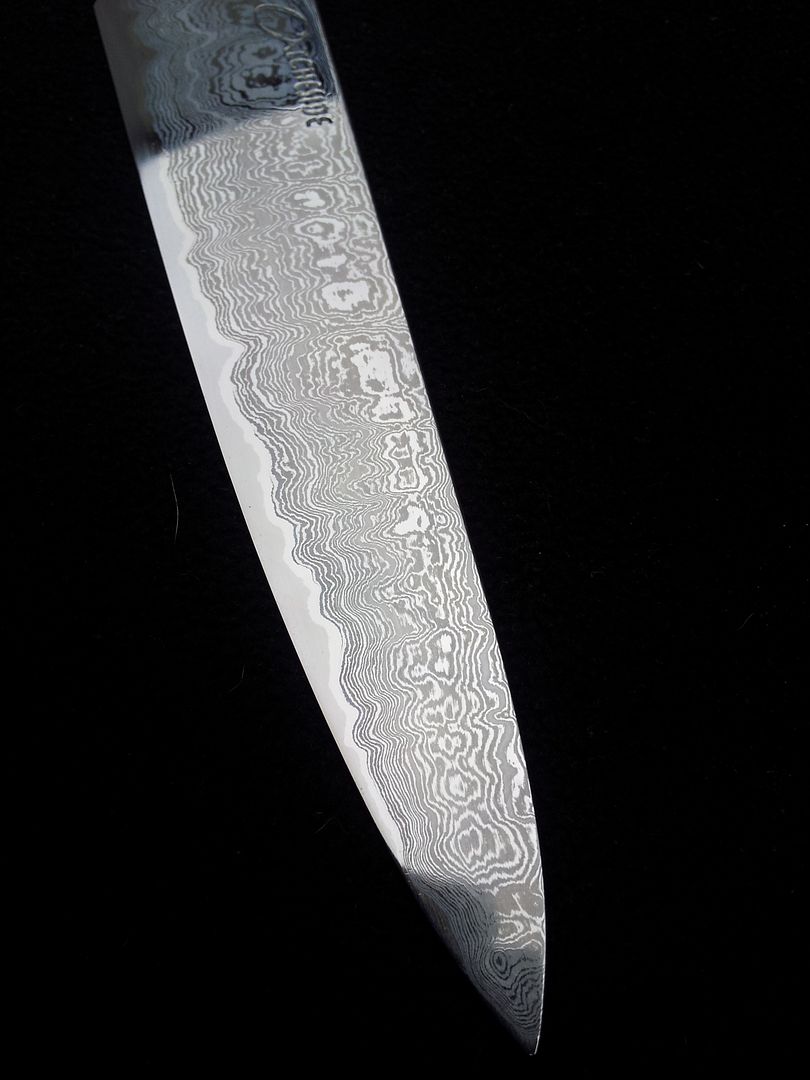

After grinding the taper and a quick etch.

Andrey

Ben

And a little carbon group, all heat cycled, ready for HT in the morning.:biggrin:

After forging and trimming the profiles.

Andrey - 240 mm Gyuto

Ben - 220mm Gyuto

After grinding the taper and a quick etch.

Andrey

Ben

And a little carbon group, all heat cycled, ready for HT in the morning.:biggrin: