TEWNCfarms

Senior Member

- Joined

- Apr 12, 2018

- Messages

- 488

- Reaction score

- 4

Thanks for the choil shots of the laser, it looks to be in good shape.

In regards to the differing HT, I'd hate to get all technical (pfft! :laughbut the elasticity of steel is pretty much constant regardless of HT - So because the laser is ground thinner over the workhorse, the thicker workhorse will naturally feel more solid (although I ground the tip on that to be thin as well), the laser springier... and there's practically nothing I can do to change it.

Here's a different way of thinking of it: Many of us have seen videos out there of great bladesmiths displaying the strength and tenacity of their heat-treatment by locking their blade vertically in a vice and bending it 90 degrees without having it crack or delaminate:

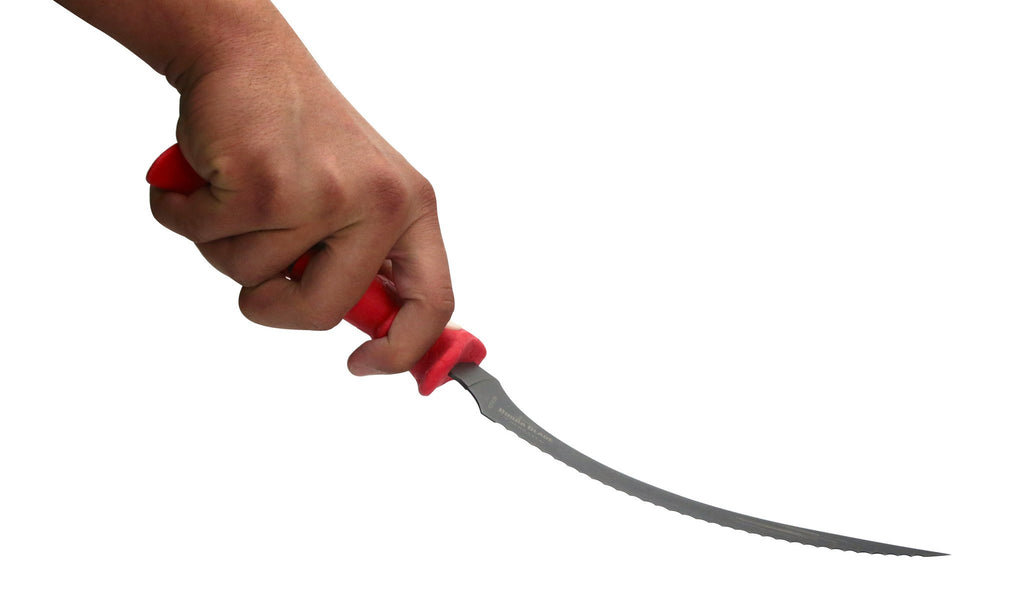

Yet if you took a cheap filleting knife, there would be no issue at all in passing the same test due to how thin it is:

A workhorse style knife would feel like a crowbar in comparison to the springy laser. There's no way around it, not without beating physics anyway.

In regards to the passaround, I think that the double concave thin-behind-the-edge knife feels awesome! :biggrin: It has a whispy feeling on the stones and a glidey feeling on the board, hard to describe but it feels great! I've always been a laser fanboy though...

So is it just how hard it feels or something? To tell the difference of heat treatment? And yeah Ive seen that thats crazy! Can you make knives that bend 90degrees? I saw an old CBS segment on Kramer and he took one of his knives he made in front of them and did the whole Masterbladesmith test and it still push cut through paper at the end! And he bent it 90 degrees and it just popped right back in place! I was blown away! Ive seen another guy do it for the MBS test and his knife didnt bend back... Kramer even cut the 2x4 in half and all the other stuff and it still push cut! I guess thats why his knives go for so much. Id be so afraid itd snap and shatter shrapnel in me