Hello everyone - long time no post... so I thought that the two knives that I currently have on their way would be an interesting topic to share.

If you look at my knife gallery (link in signature), you will see that I already have a couple of knives from Vinh Lê Cao. He was trained by a traditional Vietnamese black-smith, and has since been practicing his trade in France, as Forge de Caractère.

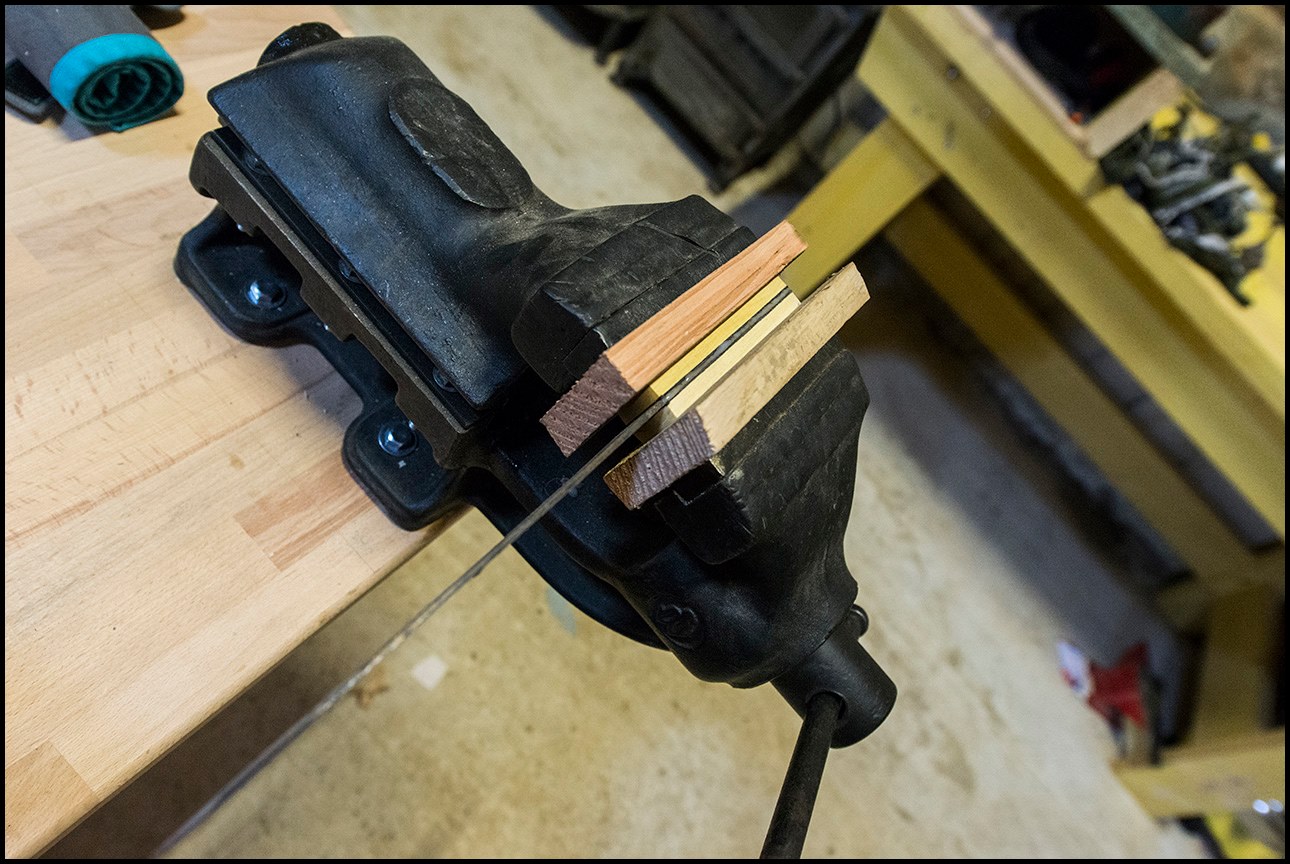

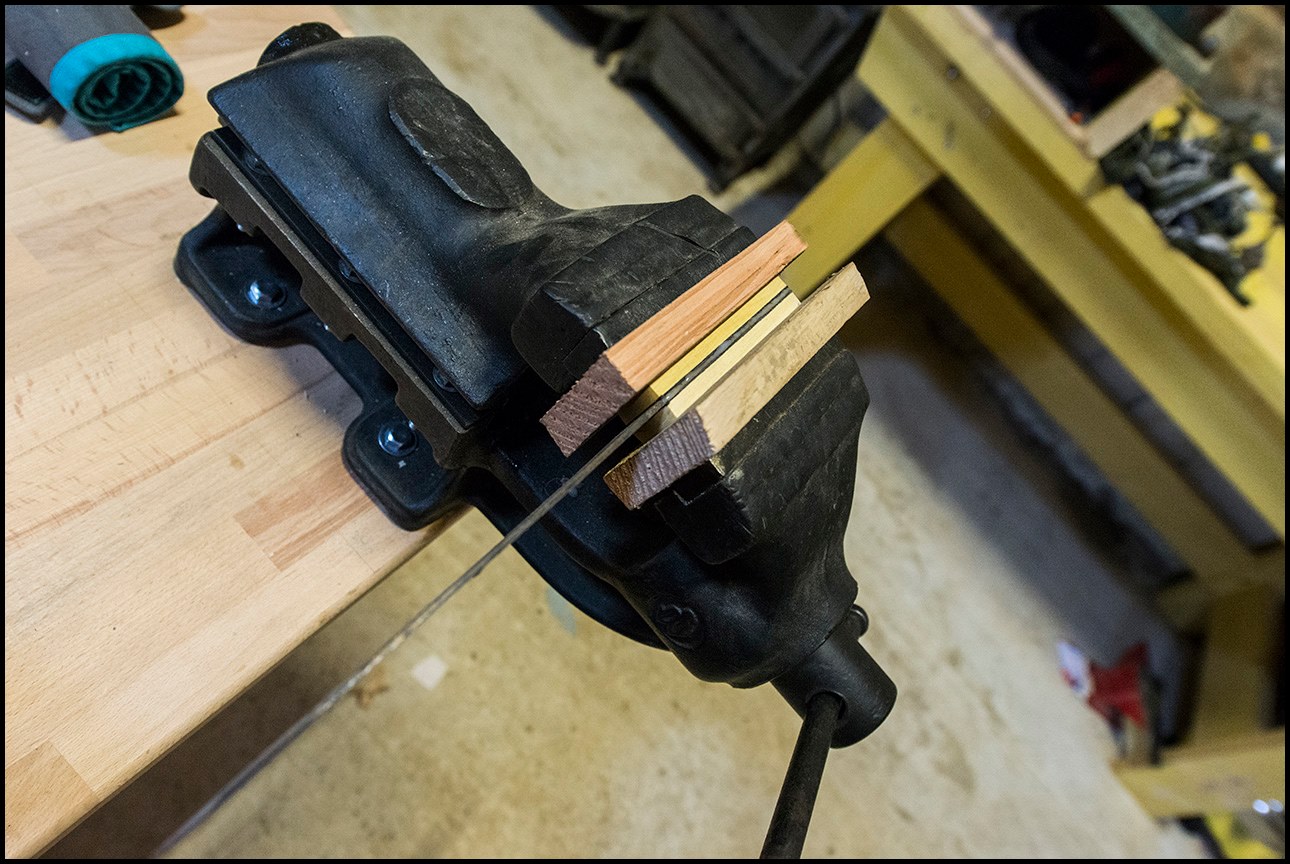

The two knives I have coming are a simple rustic Chef and Petty matched pair, with handles in boxwood. As you can see below, they were made quite traditionally, on a coal-fired forge and with selective water quenching.

I like the hamon line on the Chef knife...

Enjoy!

[All pictures from ForgedeCaractere's facebook page]

If you look at my knife gallery (link in signature), you will see that I already have a couple of knives from Vinh Lê Cao. He was trained by a traditional Vietnamese black-smith, and has since been practicing his trade in France, as Forge de Caractère.

The two knives I have coming are a simple rustic Chef and Petty matched pair, with handles in boxwood. As you can see below, they were made quite traditionally, on a coal-fired forge and with selective water quenching.

I like the hamon line on the Chef knife...

Enjoy!

[All pictures from ForgedeCaractere's facebook page]