Mike Davis

Senior Member

- Joined

- May 2, 2011

- Messages

- 1,921

- Reaction score

- 0

Those look great! I cant wait to check out some new ones in hand!

What are the woods in those handles? Do you have more pictures?

Pesky

In the meantime, african blackwood and maple burl.

Joe,

This is exactly what my interpretation of what you guys have been asking for when you talk about lasers. Yes it would be advisable to sharpen this knife with a high grit stone and not with a lot of pressure. I have been working with this steel mix for over 10 years now and I know how far I can push it. When it comes to performance its amazing. I used the passaround knife for a day in my own kitchen, to guage the slimmer profile, and WOW. It went right through a cantalope seeds and all with hardly any pressure at all and no wedging either. I also modified the handle a bit, slimmed it down at the bolster. These knives are top notch right now, and there, at this moment, seems only one issue that has been brought up that I have not yet addressed, that is of convex bevels. This will be something I will be working on in the near future.

Thanks to all of you for sharing your knowledge with me and helping me improve.

Del

I didn't realize this when looked at every single picture of your knives you have posted, or handling them at ECG, or for the first day I had mine. You have no maker's mark on the blade (or handle I suppose). You have a pretty distinctive style and I could easily pick one out of a line up, but any reason you don't have your name on these bad boys?

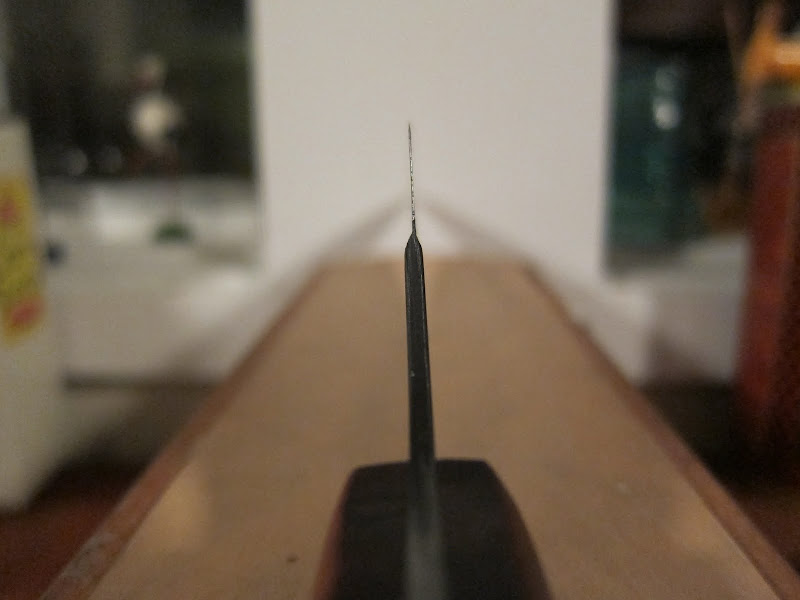

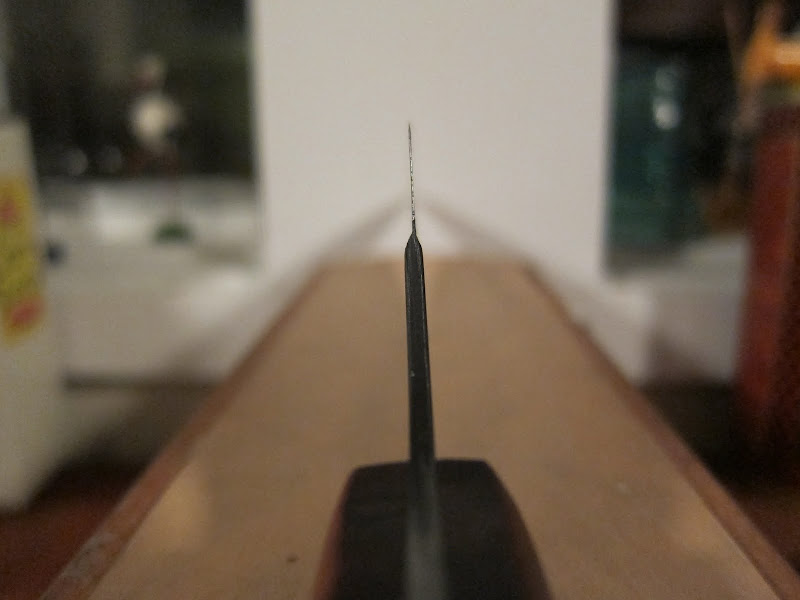

For those wondering how thin we are talkin here:

~0.35mm thick 11mm behind the edge at the heel. And this was after Del fixed it.

Enter your email address to join: