I understand the original goal was a throwback design. A solid carbon steel (O1) A solid retro-ish profile (A tweaked sab profile) Natural stable wood (cocobolo)

The hickups were on which handle. This is where we explored new territory. Some wanted wa, some wanted western, some bolsters, some no bolsters, some one pin some 3 pins. This made it tough to please everybody 100%. Ain't gonna happen...

So Here are my thoughts, to take some of most of the wants and make a handle that when looked at is understated and different, yet embodies the spirit of what we started to create.

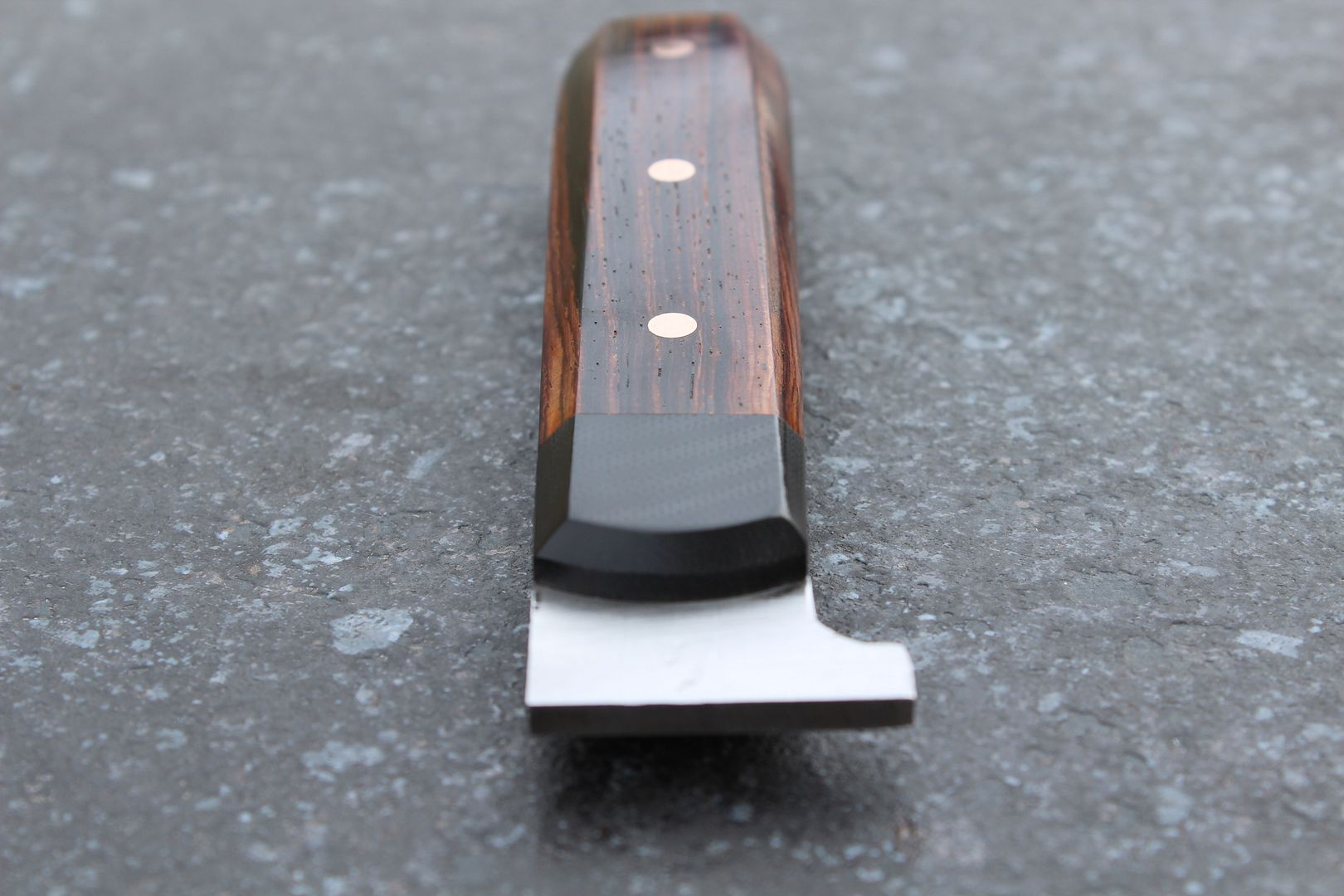

How can a geometric octagonal Wa, and a curvy western be combined? I tried to combine the taper of a wa, the height and width of a western, the facets of a wa, and some of the westerns curves and feel. How do we do a cross on a bolster, and no bolster... we cant. BUT, we can use materials that are visually subdued, and still aesthetically pleasing. Copper wasn't the answer, or the first mockup, so back to the drawing board. G10 shaped to match the facets on the handle.

How do we pay homage to the handles of old, yet not make a copy? To that end, we have the flats and beveled corners, slightly tapering handle, with three pins. Why not a traditional wood. No real reason, only there are other choices that have nice figure, are solid, and relatively stable. Why add G10? I think capping the end of the handle at the "food" end makes sense for cleanliness, comfort, and looks. Check out some of the 50 plus year old knives with straight wood handles out there. The fronts are stained, chipped, splitting, lifting etc. Could we have gone that route? Yes. Is there a real reason apart from historical accuracy to do it? I don't know. We are paying homage to an old style, top materials, and having it built by the oldest knife maker, I think, in North America. We have a chance to build the next classic (hopefully!) with input from a large group of knife enthusiasts who can say "we were part of that".

I don't want to sound corny (too late I fear! lol!) there is no way to please all of you who posted ideas, but we took what most of you liked, and trashed most of what you didn't like. All the while trying to keep some tradition in the design, and bring that tradition into the present.

Look at it this way. We have designed a knife from the ground up in a week that may not be historically accurate, but has its roots in history. When you look at it, you will see Sab, Forgecraft, and even Lamson.

We agreed to use a company that hasn't been given the time of day around here, give them a chance to do it our way, and generated some excitement doing it! Nearly 14000 views in a week! Either your interested in the knife, or your interested in the process of the design, but hell! Thanks for being part of it!

Now. Any other things we need to work on? We got time and resources! A prototype is next!