It just so happens that for a short period of time I have the possibility to use in parallel 3 Gesshin stones (400, 2k, 6k) and 2 JNS stones (800, 6k). I am the lucky owner of the Gesshin setup, but the JNS stones are meant as a present.

Anyhow - I though that I should get my hands on the JNS stones before passing them on to their rightful owner and share here my impressions and thoughts

Please note that this is not supposed to be a full review or head-to-head comparison. Mainly because I am not experienced enough for the former and because of the differences in grit and personal preferences for the latter.

These stones are a mix of soakers G400, G2k and JNS800 and splash&go stones (both 6k). But since all of these stones can be perma-soaked, I have soaked them all for about the same period of time prior to use. The shortest soak time for 30 minutes which should be enough for all of these stones.

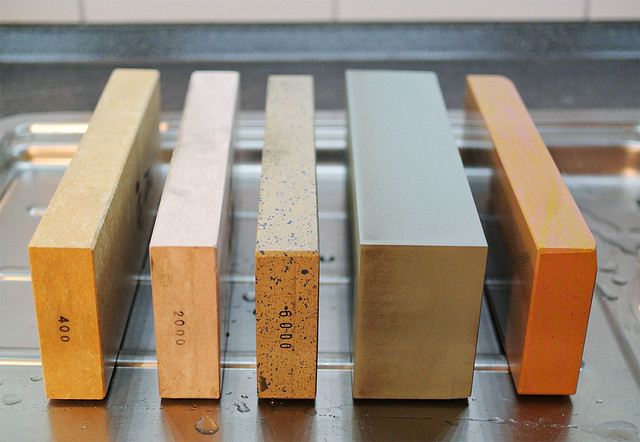

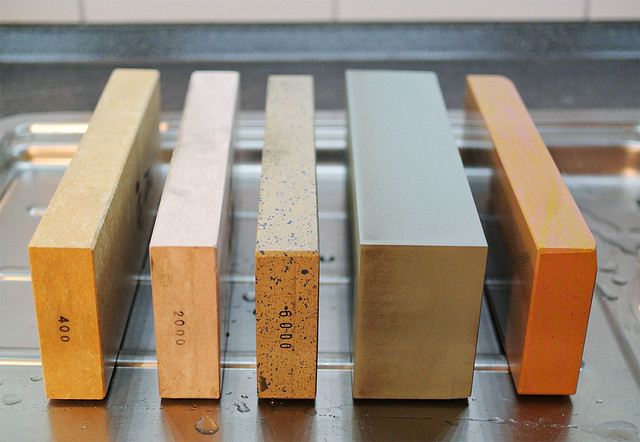

So - the stones soaking nicely. This is after about 20 minutes. The G400 and JNS800 still bubble slightly. From left to right: G400, G2k, G6k, JNS800 and JNS6k:

The knives.

I have used a mix of carbon, stainless and semi-stainless knives. Some needed just a slight retouch, but some had light blade damage or micro-chipping, that justified the use of coarser stones.

(a) 130 mm no-name low end wwestern style stainless petty/pairing knife which is rather thick behind the edge. Was rather dull, so it got a full workout.

(b) 80 mm SLD Yoshikane petty - had some edge damage after I tried to trim a bunch of flowers without noticing that there are some thinner branches in the bunch what resulted in chipping and even some edge-rolling. I misused the knife and got the results I had to get :-\

(c) 150 mm VG10 (core) SHUN petty with micro-chips along the full length of its edge.

(d) 150 mm Zakuri Sabaki Bocho in Super Blue #1. This is a stronger knife (4.5 mm at the spine close to handle), but the edge is not as robust - had a few micro-chips from the same work as the Yoshi, but these were really minor. My plan is to make the edge a little stronger in the course of the future sharpening sessions as the main task for this knife is supposed to be de-boning.

(e) 210 mm Tanaka R2 (damascus clad) thin laser gyuto - the knife only needed slight touch-up so it was only sharpened with 2000 and 6000 stones.

It needs to be noted that while none of knives sharpened have wide bevels, so the the finish of each of the stones could only be observed close to the edge.

The knives:

I have used the Suehiro stone holder + plastic base from JKI which I found very practical. (I got my hands on the Naniwa bridge sink, but did not like it and returned it - I will make a separate thread about that later)

The process:

Gesshin 400:

I have started with knife (a) and (b) on the G400 stone. The (a) knife is not particularly nice to sharpen, but the process was fast. The G400 is to me a stone of medium hardness. It will work up some nice mud, but it did take a while (about half way through working on the first knife). It is a thirsty stone. I was adding a few drops of water (not too much - just to keep the mud) for every time a flipped the knife. Sharpening the (b) on the G400 was a pure joy - It took me just a few minutes and the edge was repaired.The G400 would be the fastest wearing stone of the bunch, but I would definitely NOT consider it wearing fast. After working on 10 blades it starts to show hints of wear, but still not enough to justify flattening. This is a coarse stone, so it is not going to give you a silky feel, but it does give you nice feedback. Also remember - this is a coarse stone and it leave scratches you may not find attractive for a surface finish IMO.

Gesshin 2000

Left: ready to use, Right: After some 20 strokes

-

-

I then moved to G2k with (a) and (b) knives. The G2k is much harder stone. In fact - as you can see in photos - it takes some of the steel and gives the optical impression of clogging. BUT that is just optics. It keeps cutting VERY fast and raising a burr was right down easy. Again, the SLD steel of knife (b) was pleasure to work with. (a) was not much effort either, just not so pleasurable. Concerning the wear - the stone has seen some 20 blades and there are no signs of wear yet. The stone feels nice (not as smooth as the 6000 though). The step from 400 to 2000 felt just right. Even though the scratch pattern of the 400 is rather obvious, the speed of the 2000 removed these with just few movements. The stone needed just a little more water than either of the 6k stones and much less than the coarse ones. The scratch pattern is smooth. One could probably use it as last stone for some knives, I personally would find the edge a bit too toothy, but it could be done.

Gesshin 6000

Left: ready to use, Right: After some 20 strokes:

-

-

Finally - both (a) and (b) knives got a final round on G6k stone. This stone feels really nice. It is not as hard as the G2k, but still on the harder side. It feels great and gives nice feedback. Dishing is not going to be a problem - the stone dishes slow and as it is a finishing stone - the heavy lifting was done by coarser stones.

(It needs to be noted that during the second part I concentrate more on sharpening and less on photographing and so I missed the "action" photos of the JNS stones. I will fix that with my next session - if I manage one before shipping the JNS stones)

JNS 800 (the big one)

Now onto knives (c) and (d). The (c) - Shun - needed bit more work because of the micro-chipping. Now I took the JNS800 for the job. This stone is harder than Gesshin 400, but softer than the rest of all these stones. It feels really nice for 800 and leaves surprisingly smooth scratch pattern (mat of course). It proved to have no problem eating away the VG10 and the microchips disappeared faster than I have expected. The (d) knife did not need all that much work (few microchips), but I wanted to get the blade a bit thicker. The carbon steal felt great on the stone. I got the job done in no time. Dishing of this stone is on the slow side - I did not manage to get too much mud out of it. Feels very nice too. And I LOVE the size. I wish all stones would come in this size The water 'consumption' was very comparable to Gesshin 400. So on the thirsty side - but again - I do not find that to be a problem.

The water 'consumption' was very comparable to Gesshin 400. So on the thirsty side - but again - I do not find that to be a problem.

JNS 6000

Finishing both (c) and (d) knives was a pure joy - the stone has very silky feel - actually very similar to Gesshin 6000. But is is harder than the Gesshin. I also expect the stone to last for a very long time in home environment. Thanks to very smooth scratch pattern of the JNS 800, the step all the way up to JNS 600 was no-issue. I did not feel the need for a stone in between. This stone will - similarly to G2k - give the optical impression of clogging, but it keeps cutting very fast.

Tanaka R2 @ G2k, G6k, JNS6k

I kept the Tanaka to be sharpened as last - remember - I am still learning the technique and this is my best knife. I started on G2k and got the burr VERY fast. Needles to say - the knife did not need much work. Then I moved on the 6k stones - on purpose I switched them twice to see whether I am going to see some relevant difference. I was surprised, but there was not much difference. The JNS is harder then Gesshin, but this only became visible during trailing (I could get a very slight 'trace' on the G6k if I would make the movement wrongly). and even then it was rather subtle. Both 6k stones give great feel, need very little water and both produce pretty much a mirror polish.

After the work:

So - my final thoughts:

G400: fast, produces mud, medium wearing, medium hardness, thirsty

G2k: fast, no mud, little wear, hard, needs little water, good feel,

G6k, fast, no mud, medium hard, very little water, great feel, nice finish

JNS 800: fast, not muddy, hard-ish, slow wear (tbc), thirsty, smooth scratch pattern

JNS 6000: fast, no mud, hard, slow wear (tbc), needs little water, great feel, nice finish

*************

I really enjoy my Gesshin setup - the 2000 stone is in particular a great one for me, since if knife does not need any repair or is not completely dull it is a great stone to start. I grab the 400 for the rougher work.

On the other hand the JNS 800 and 6000 stones work really well together. The JNS is fast enough to do nearly all you need (for re-profiling one would probably get a really coarse stone - the JNS 300 would be my first guess) with a dull of micro-chipped blade and thanks to its smoothness the 6000 works great as a finisher.

Thanks goes to Jon @ JKI and Maksim @ JNS for their help choosing these setups :thumbsup:

I hope you enjoyed this LOOONG write-up

Anyhow - I though that I should get my hands on the JNS stones before passing them on to their rightful owner and share here my impressions and thoughts

Please note that this is not supposed to be a full review or head-to-head comparison. Mainly because I am not experienced enough for the former and because of the differences in grit and personal preferences for the latter.

These stones are a mix of soakers G400, G2k and JNS800 and splash&go stones (both 6k). But since all of these stones can be perma-soaked, I have soaked them all for about the same period of time prior to use. The shortest soak time for 30 minutes which should be enough for all of these stones.

So - the stones soaking nicely. This is after about 20 minutes. The G400 and JNS800 still bubble slightly. From left to right: G400, G2k, G6k, JNS800 and JNS6k:

The knives.

I have used a mix of carbon, stainless and semi-stainless knives. Some needed just a slight retouch, but some had light blade damage or micro-chipping, that justified the use of coarser stones.

(a) 130 mm no-name low end wwestern style stainless petty/pairing knife which is rather thick behind the edge. Was rather dull, so it got a full workout.

(b) 80 mm SLD Yoshikane petty - had some edge damage after I tried to trim a bunch of flowers without noticing that there are some thinner branches in the bunch what resulted in chipping and even some edge-rolling. I misused the knife and got the results I had to get :-\

(c) 150 mm VG10 (core) SHUN petty with micro-chips along the full length of its edge.

(d) 150 mm Zakuri Sabaki Bocho in Super Blue #1. This is a stronger knife (4.5 mm at the spine close to handle), but the edge is not as robust - had a few micro-chips from the same work as the Yoshi, but these were really minor. My plan is to make the edge a little stronger in the course of the future sharpening sessions as the main task for this knife is supposed to be de-boning.

(e) 210 mm Tanaka R2 (damascus clad) thin laser gyuto - the knife only needed slight touch-up so it was only sharpened with 2000 and 6000 stones.

It needs to be noted that while none of knives sharpened have wide bevels, so the the finish of each of the stones could only be observed close to the edge.

The knives:

I have used the Suehiro stone holder + plastic base from JKI which I found very practical. (I got my hands on the Naniwa bridge sink, but did not like it and returned it - I will make a separate thread about that later)

The process:

Gesshin 400:

I have started with knife (a) and (b) on the G400 stone. The (a) knife is not particularly nice to sharpen, but the process was fast. The G400 is to me a stone of medium hardness. It will work up some nice mud, but it did take a while (about half way through working on the first knife). It is a thirsty stone. I was adding a few drops of water (not too much - just to keep the mud) for every time a flipped the knife. Sharpening the (b) on the G400 was a pure joy - It took me just a few minutes and the edge was repaired.The G400 would be the fastest wearing stone of the bunch, but I would definitely NOT consider it wearing fast. After working on 10 blades it starts to show hints of wear, but still not enough to justify flattening. This is a coarse stone, so it is not going to give you a silky feel, but it does give you nice feedback. Also remember - this is a coarse stone and it leave scratches you may not find attractive for a surface finish IMO.

Gesshin 2000

Left: ready to use, Right: After some 20 strokes

-

-

I then moved to G2k with (a) and (b) knives. The G2k is much harder stone. In fact - as you can see in photos - it takes some of the steel and gives the optical impression of clogging. BUT that is just optics. It keeps cutting VERY fast and raising a burr was right down easy. Again, the SLD steel of knife (b) was pleasure to work with. (a) was not much effort either, just not so pleasurable. Concerning the wear - the stone has seen some 20 blades and there are no signs of wear yet. The stone feels nice (not as smooth as the 6000 though). The step from 400 to 2000 felt just right. Even though the scratch pattern of the 400 is rather obvious, the speed of the 2000 removed these with just few movements. The stone needed just a little more water than either of the 6k stones and much less than the coarse ones. The scratch pattern is smooth. One could probably use it as last stone for some knives, I personally would find the edge a bit too toothy, but it could be done.

Gesshin 6000

Left: ready to use, Right: After some 20 strokes:

-

-

Finally - both (a) and (b) knives got a final round on G6k stone. This stone feels really nice. It is not as hard as the G2k, but still on the harder side. It feels great and gives nice feedback. Dishing is not going to be a problem - the stone dishes slow and as it is a finishing stone - the heavy lifting was done by coarser stones.

(It needs to be noted that during the second part I concentrate more on sharpening and less on photographing and so I missed the "action" photos of the JNS stones. I will fix that with my next session - if I manage one before shipping the JNS stones)

JNS 800 (the big one)

Now onto knives (c) and (d). The (c) - Shun - needed bit more work because of the micro-chipping. Now I took the JNS800 for the job. This stone is harder than Gesshin 400, but softer than the rest of all these stones. It feels really nice for 800 and leaves surprisingly smooth scratch pattern (mat of course). It proved to have no problem eating away the VG10 and the microchips disappeared faster than I have expected. The (d) knife did not need all that much work (few microchips), but I wanted to get the blade a bit thicker. The carbon steal felt great on the stone. I got the job done in no time. Dishing of this stone is on the slow side - I did not manage to get too much mud out of it. Feels very nice too. And I LOVE the size. I wish all stones would come in this size

JNS 6000

Finishing both (c) and (d) knives was a pure joy - the stone has very silky feel - actually very similar to Gesshin 6000. But is is harder than the Gesshin. I also expect the stone to last for a very long time in home environment. Thanks to very smooth scratch pattern of the JNS 800, the step all the way up to JNS 600 was no-issue. I did not feel the need for a stone in between. This stone will - similarly to G2k - give the optical impression of clogging, but it keeps cutting very fast.

Tanaka R2 @ G2k, G6k, JNS6k

I kept the Tanaka to be sharpened as last - remember - I am still learning the technique and this is my best knife. I started on G2k and got the burr VERY fast. Needles to say - the knife did not need much work. Then I moved on the 6k stones - on purpose I switched them twice to see whether I am going to see some relevant difference. I was surprised, but there was not much difference. The JNS is harder then Gesshin, but this only became visible during trailing (I could get a very slight 'trace' on the G6k if I would make the movement wrongly). and even then it was rather subtle. Both 6k stones give great feel, need very little water and both produce pretty much a mirror polish.

After the work:

So - my final thoughts:

G400: fast, produces mud, medium wearing, medium hardness, thirsty

G2k: fast, no mud, little wear, hard, needs little water, good feel,

G6k, fast, no mud, medium hard, very little water, great feel, nice finish

JNS 800: fast, not muddy, hard-ish, slow wear (tbc), thirsty, smooth scratch pattern

JNS 6000: fast, no mud, hard, slow wear (tbc), needs little water, great feel, nice finish

*************

I really enjoy my Gesshin setup - the 2000 stone is in particular a great one for me, since if knife does not need any repair or is not completely dull it is a great stone to start. I grab the 400 for the rougher work.

On the other hand the JNS 800 and 6000 stones work really well together. The JNS is fast enough to do nearly all you need (for re-profiling one would probably get a really coarse stone - the JNS 300 would be my first guess) with a dull of micro-chipped blade and thanks to its smoothness the 6000 works great as a finisher.

Thanks goes to Jon @ JKI and Maksim @ JNS for their help choosing these setups :thumbsup:

I hope you enjoyed this LOOONG write-up