Luftmensch

Senior Member

- Joined

- Dec 13, 2017

- Messages

- 2,316

- Reaction score

- 3,186

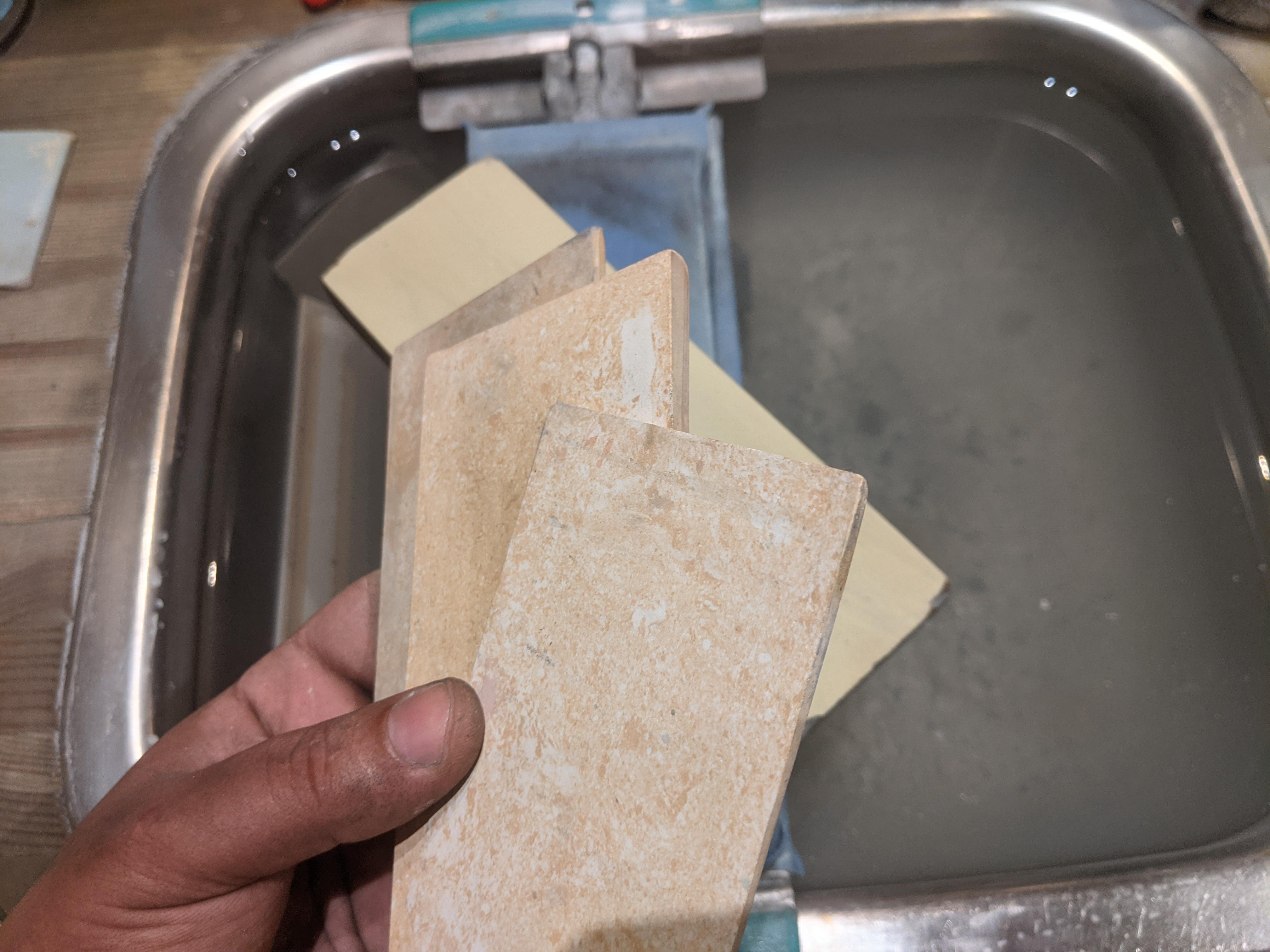

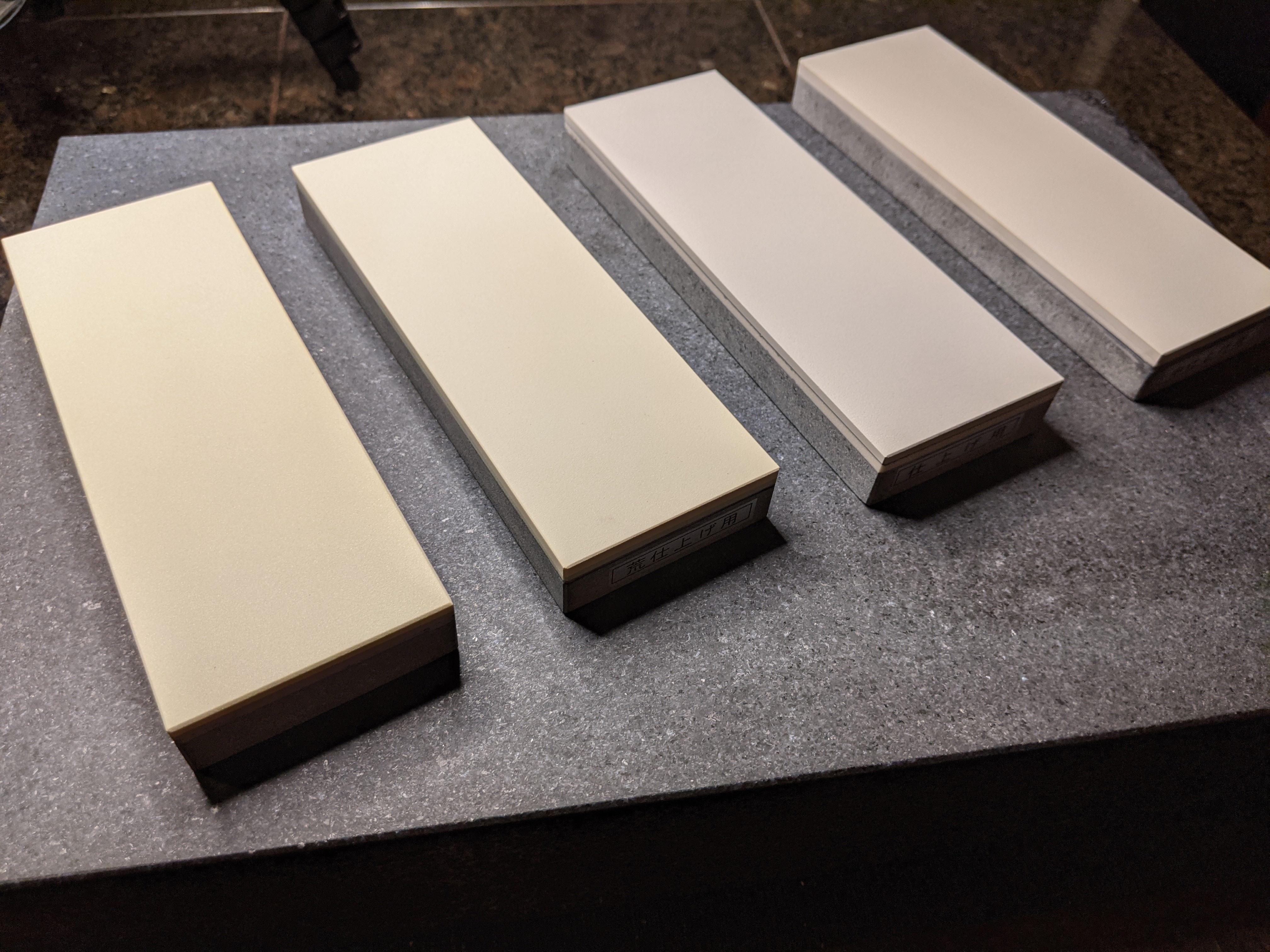

Regarding the Crystolon. It's like the grinding on the Sigma 240, but, the teeth clenching grinding is ramped up 100x. And stays flatter waaayyy longer.

Yuck. Last night I tried 80(?) grit SiC on the shapton 120.... The grains are about the size of sugar grains or coarse sand... Man was that unpleasant. Not quite as bad as scratching fingernails across a blackboard... but moving in that direction!