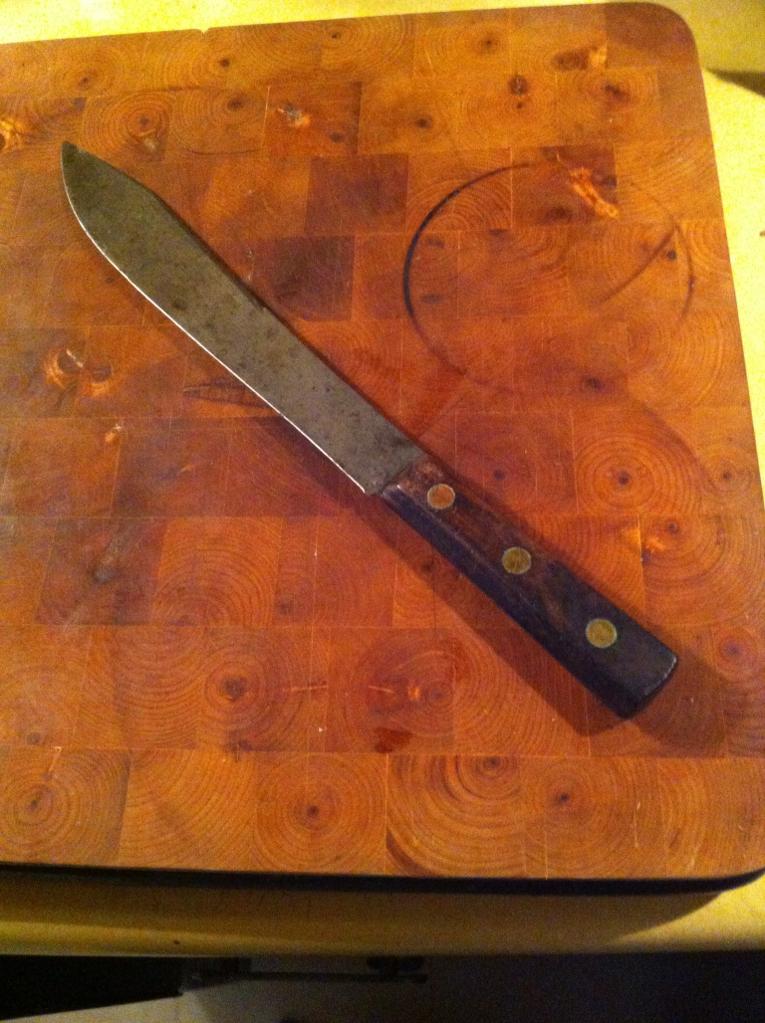

Now this is a pair worth having:

Again, I'm crammed for time, but these are available. The scimitar is 12" long, and the cleaver is approx 7". Both have tight, secure handles and a good working edge will be put on them at time of sale. My site is taking a little too long to load up on my end, thus the items on here.

Scimitar price: $55

Cleaver price: $45

$12 shipping for you guys. We'll split the difference

PM if interested.

Again, I'm crammed for time, but these are available. The scimitar is 12" long, and the cleaver is approx 7". Both have tight, secure handles and a good working edge will be put on them at time of sale. My site is taking a little too long to load up on my end, thus the items on here.

Scimitar price: $55

Cleaver price: $45

$12 shipping for you guys. We'll split the difference

PM if interested.