Hi all!

This knife was made by me, I am also at a loss as to what it could be.

I would like to immediately exclude a number of questions.

1. I know about abrasive hygiene and the pre-finish and finishing tapes are different for rusting and stainless steel.

2. There is no varnish or anything like that on the blade, it is finished with Р-320 tape.

3. There is absolutely no doubt that this is a genuine MagnaCut.

In my practice, I encountered something similar on the M390, but these stains were less noticeable, and I did not identify any kind of system. After regrinding the blade, this stain no longer appeared on one knife, but on the second it appeared within the same boundaries and of the same shape.

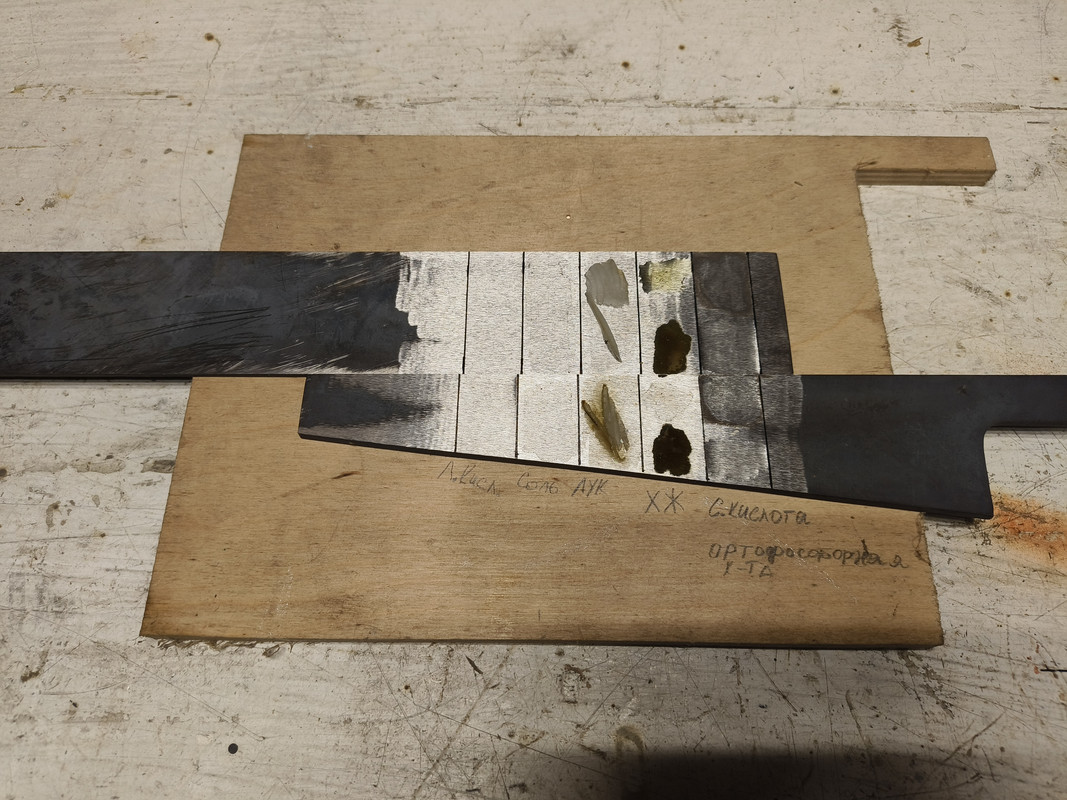

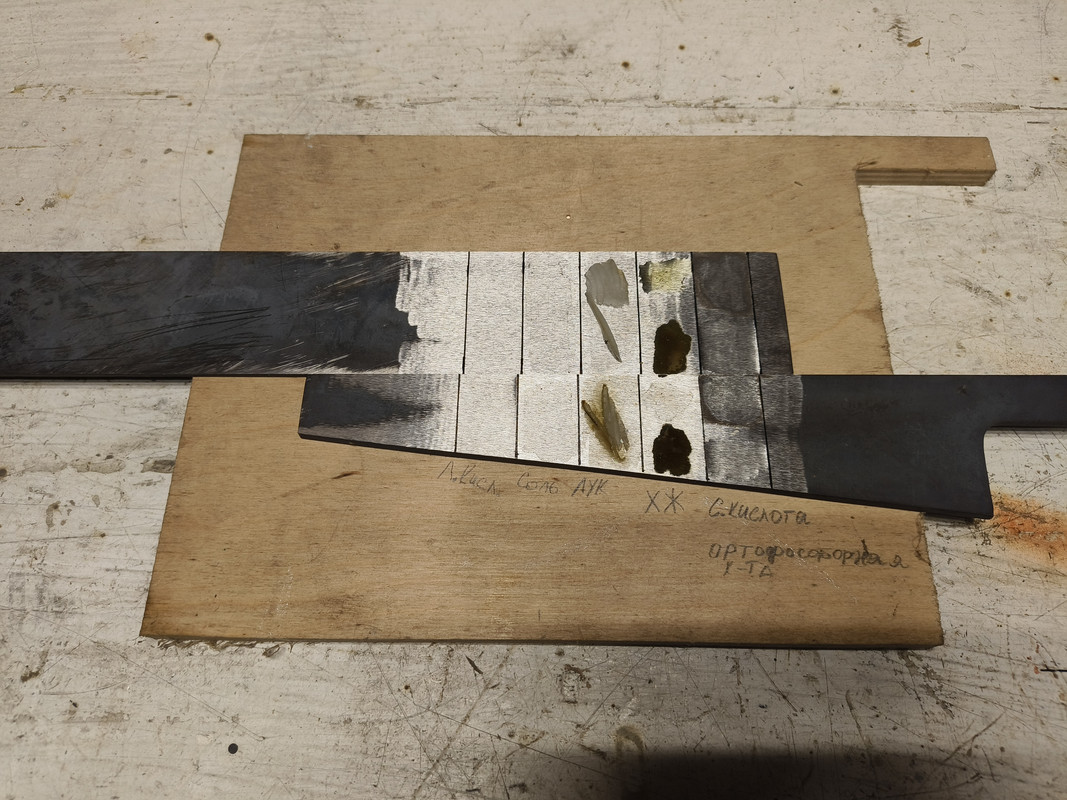

I decided to do a primitive test of this MagnaCut.

I have this steel in two thicknesses, so I decided to test both strips.

The following aggressive media were involved (from left to right): citric acid solution, salt solution, onion, ferric chloride, phosphoric acid and hydrochloric acid.

I diluted solutions of citric acid and soda until the crystals stopped dissolving, squeezed out the juice from the onion and put a few pieces on top.

Also, the first knife I made from MagnaCut, as an edge retention test, spent about a month in a professional kitchen, and there were no marks left on it, the steel was from the same batch.

Three and a half hours passed and what I saw was that citric acid, salt, onion, orthophosphoric acid did not leave any traces, although I was sure that the brine solution was supposed to harm the steel. The darkest stains were left by ferric chloride, but I must say I applied two drops of ferric chloride to each area, concentrated and a regular etching solution, the stain remained only from the concentrate.

Although hydrochloric acid did not leave such a dark stain as ferric chloride, it caused the deepest damage.

This test did not shed any light on the cause of the stains and leaves open the question of what causes this “patina.”

I'm sure Ptolemy nothing to do with the appearance of this patina, because it is stainless steel. He also has a second small knife and both knives are made from the same strip of steel, which has not tarnished.