I was kidding, just about the "professional reason" to dislike Henckels. Henckels makes knives because that is what people buy--if people stop buying knives altogether in lieu of food processors, they'd start making those. My issue with Wusthof is their misinformation tactics that they employ at cooking schools, retail outlets, etc. And their knives are really bad. I see no difference between a $80 Wusthof and its $15 knock off in practice. I have no reason to be biased about this stuff, I, as of yet, have not made entire knives for sale.

Regarding the actual issue at hand, here's what I'm talking about. This is a ZK I got from someone who is not on these forums(just a guy wanting a sheath), I have not touched this knife with the stones, yet. This is the heel on one side:

And this is the other, clearly mismatched.

And you can also see from the reflection of the straight window panes on the blade that the grind is low in one spot. That proceeds all the way to the edge, and is not matched on the other side.

Here's an Addict, which I have taken to the stones, for just a second, before I noticed the issue with the heel, at which point I set it down to deal with later.

The heel on the other side:

The grinds are also oriented on both to match the centerline of the blade, because it is easier to get the machines to make knives in straight passes, and having a machine that can follow the profile of a knife when grinding would be outlandishly expensive, or else require many more passes on the machine to create(and every pass adds a significant amount of money to the price of the knife). I have spoken directly to the Lamson folks about this, and I did not get a clear answer as to why the machines have so much trouble creating consistent grinds, other than that the machines are not meant to grind at tolerances that low, and start to act wonky. They were designed, after all, during the era when the Wusthof and Henckels and Chicago Cutlery and Ginsu were filling everyone's homes with useless disposable plates of steel. It is just the way the machines are made. I cannot say about the ZKs, but Lamson does not finish grinding by hand.

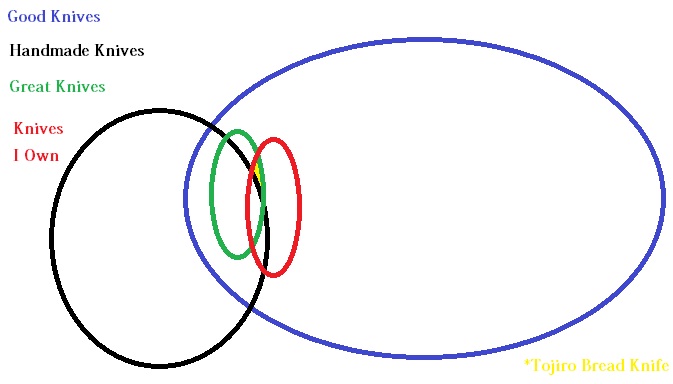

The point I was making is, these are not handmade knives. A human does not require more compensation every time they take an extra step at work, or for bending their elbow. It is ok to use a not-handmade knife. I use them often. But I don't see why people would want to pay handmade prices and get factory performance. And by performance, I don't just mean cutting or HT, but also maintenance, and the ability to be used up over your life and continue working while doing so. One of the reasons I like my handmade knives is because they are a breeze to sharpen--I spend just a few minutes and the knife is in tip top shape again, and I don't have to worry about enlarging a hole, making sure to out-size an overgrind on a dead flat stone, or compensating for inverted thickness behind the tip, all things that you deal from factory knives with lower QC.

A good example of a company that is kicking ass at making factory knives with excellent QC is Suisin. I have not seen any untouched Suisin knife that I can recall with any performance related defects, and the prices are all comparable to these other ones. Changing the profile, shape, etc is just a matter of style, that could be done without changing QC, design, or process. It seems that rather than make a knife at $400 with a simpler handle and less marketing hype, they would rather make a sexy knife and sacrifice in the department of being a reliably awesome cutting implement. The comparison to the Addict was because the Addict is a similarly made knife, but less makeup, and less than half the price. That is their purpose, to get a knife is crazy blade steels with attributes of a nice knife for a price that is within reach for regular people. If they wanted to, they could fix the grind issues by taking their time and making more passes...but then the knife would be...well, maybe $400. Which brings us back to the ZK.

As far as the return policy, I have a direct analogy to that in the world of folders. I bought a really great folder a while back that was made by Buck, had a great flipper design, nice profile, solid lockup, pretty scales in premium materials, and high performance heat treat of a powder metal steel. The Buck Vantage Pro. The problem is, most of them have issues with grazing the liners when they close, which can really damage a folder in use. So you might have to return a few, or look at a bunch, which is what I did--out of 8 that Outdoor World had, 6 had a serious problem. It was also under $70, which is remarkable for what you are getting, because, just like when you do finishing work on a Japanese knife to sand a spine or round off a handle, they are passing on a job to YOU--but instead of finishing, it's quality control.

I guess you are paying $250 extra because Sur La Table is fun and the bubbly handle floats your boat. I just think it could be a lot better in the area of being a cutting tool, given the price.

:2cents: