It will be difficult for me to reply in any depth due to my position in this forum, but I will try.

Yes, it was meant positively. His geometry/grind is absolutely based off of his sword making experience. I only know one other maker who is using similar concepts and education/experience, though he is applying them a bit differently.

It's also not a 'v' grind at all. The curvature in the sides of the blade is called 'niku', and how the blade cuts is absolutely a function of it. Even completely dull that blade will still cut better than many (if not most) sharpened knives. With an edge it's something else entirely. A good maker will often check his blades by cutting food before putting an edge on them for that very reason. If it won't cut cleanly before sharpening (and by 'cleanly' I don't mean drop through a tomato, though with a proper grind on it before sharpening it may actually do that), then the edge is just a band-aid/crutch for an inferior knife.

As for maintainability, you're right in some ways. Thinning should be performed in a different manner than you would on a typical 'v' grind knife as you put it. More of a blending than a true thinning, and starting higher on the blade. Most guys in the kitchen knife world think of everything in terms of flat angles. Sharpening/thinning is strictly a matter of scrubbing away on a stone while holding the spine of the knife at a precise distance from the stone. Thinning this is a bit different, but everything in this world is a compromise. That's one I think is well worth it.

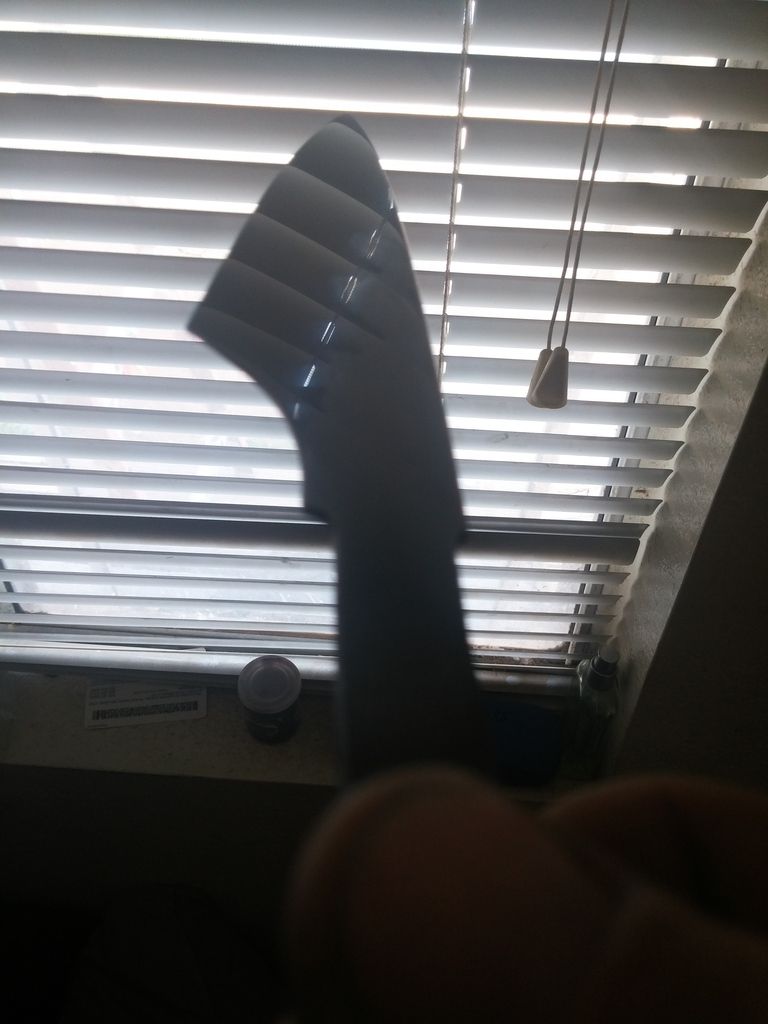

One last thing. If you want to check the grind on a blade, hold it horizontal in a dim room, pointed towards a set of blinds or other horizontal light source. With a sword you can do so like this:

With a kitchen knife, it's likely too thin (yes, even a Kato lol) to do it like that, so you would do it as I explained above:

You can learn the same amount about a sword by doing the same thing. If you tip it up and down in the light, you can see the reflection of the blinds change along the blade, showing you how the grind changes.

Hopefully that helps fill in some blanks.