- Joined

- Jun 13, 2013

- Messages

- 1,796

- Reaction score

- 23

My walnut Mag-Blok got wet and warped from sitting on a counter top. I tried to re-glue the top veneer back on to no avail so I yanked out the magnets. 5 rectangular magnets attached to a steel block. It's been sitting around for a while.

Also a while back I bought a hunk of neat looking cocobolo that I figured would be good for this and who knows what else, so I finally got around to the project. It is maybe a 3 foot board with nice sapwood in spots. Only room left in the kitchen is for a 12"-ish knife rack for longer knives like sujis. My main block is a longer one from JKI.

Meager tools to work with... Cheap a$$ table saw, miter, drill press. 1/2" router bit in the drill press worked fine to route a channel for the magnets leaving about 1/16" of material at the bottom.

Then I just cut a couple strips from waste, sandwiched them in the back with titebond, and clamped until dry. Ran through the table saw to clean up the back, hand sanded the edges and corners, disc sanded everything else smooth.

I'm FAR from a woodworker and it's far from perfect, but it came out decently. Been oiling and buttering. It's smooth and works great. I still need to hang it which is a nightmare with my old plaster walls.

Also a while back I bought a hunk of neat looking cocobolo that I figured would be good for this and who knows what else, so I finally got around to the project. It is maybe a 3 foot board with nice sapwood in spots. Only room left in the kitchen is for a 12"-ish knife rack for longer knives like sujis. My main block is a longer one from JKI.

Meager tools to work with... Cheap a$$ table saw, miter, drill press. 1/2" router bit in the drill press worked fine to route a channel for the magnets leaving about 1/16" of material at the bottom.

Then I just cut a couple strips from waste, sandwiched them in the back with titebond, and clamped until dry. Ran through the table saw to clean up the back, hand sanded the edges and corners, disc sanded everything else smooth.

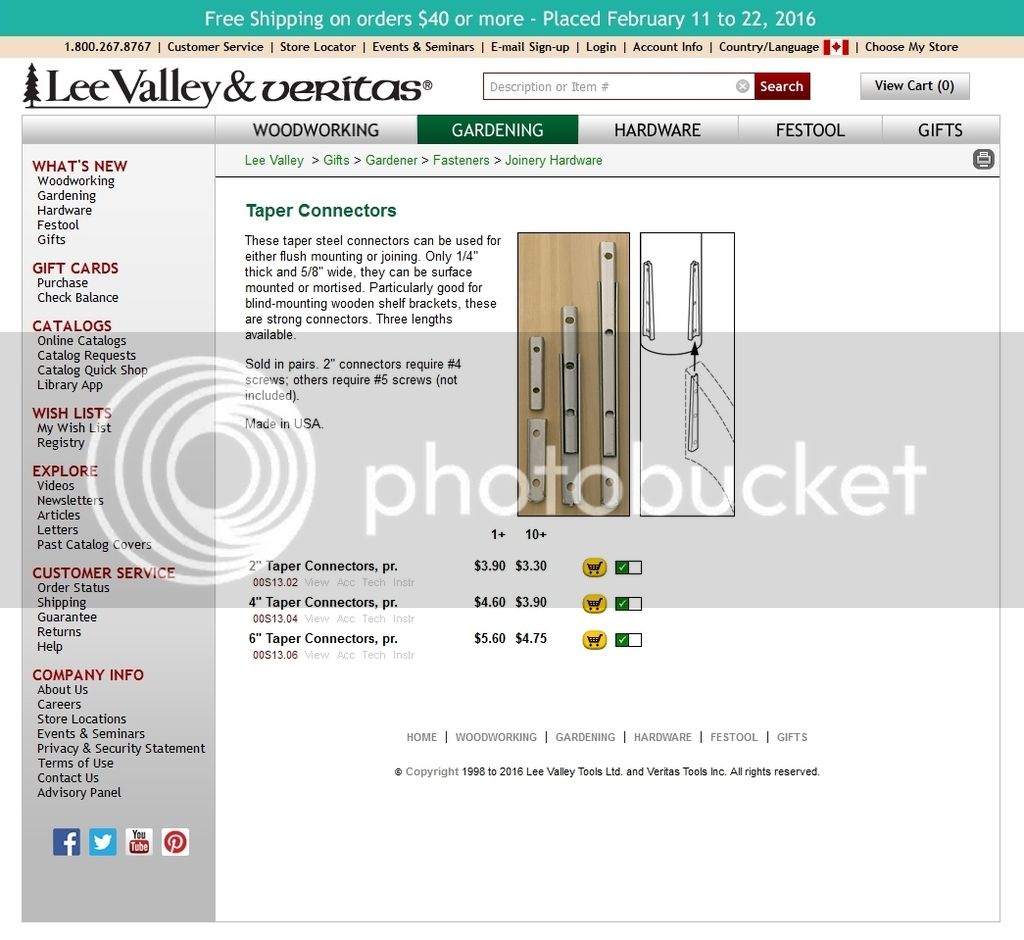

I'm FAR from a woodworker and it's far from perfect, but it came out decently. Been oiling and buttering. It's smooth and works great. I still need to hang it which is a nightmare with my old plaster walls.