@tostadas I hope this helps some...

The block in the picture is a touch over 90mm tall so a little shorter than a lot of main handle (meant to go with a ferrule) pieces and the bit is a standard one. The blue tape on the bit is marked at 80mm.

1) These pictures show the table all the way down with the block atop it and the bit in the full upright position. So you can see, that won't work:

2) This picture shows the block directly on the press base and the bit all the way down. So there's room to fit the block under the bit but still a no-go as you don't have enough travel:

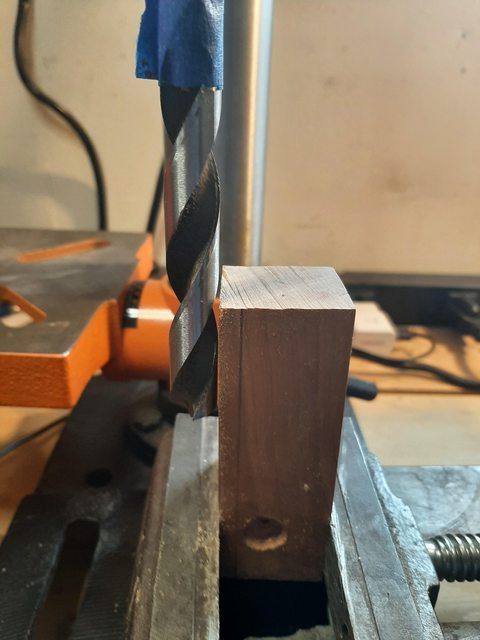

3) You have to hold the block tight, especially for the 1/2" bit and you have to get it up high enough to get some semblance of a hole, so here you see my vice on the press base:

4) And here with the bit fully extended down, so about a third to half the end-hole depth:

Sorry for my confusing posts earlier. I've tried so many different combinations trying to find what works that they all sort of blended together so I figured I'd try to do it right and let the pictures do the bulk of the explaining.

Again, with the stubby bits I can get full-bit depth with the table but that only gets ya started and I need a 1/2in stubby. I think with that I'll be good to go by then using the hand drill to finish the depth.

If you have any questions, want measurements, etc. please ask and I'll do my best to answer.