Kippington

A small green parrot

...I'd say it doesn't really matter if it has a handle or not...

...I have yet to flick a forged gyuto with any handle on them that would not "ring". at least some what. but I have flicked several non forged knives and again regardless of handle the sound has always been more muted.

I have to disagree. I think the handle has a huge effect.

I recorded this as a video response. This knife was forged and heat treated by me, 1084 monosteel.

[video=youtube;8CcQLDNh7bQ]https://www.youtube.com/watch?v=8CcQLDNh7bQ[/video]

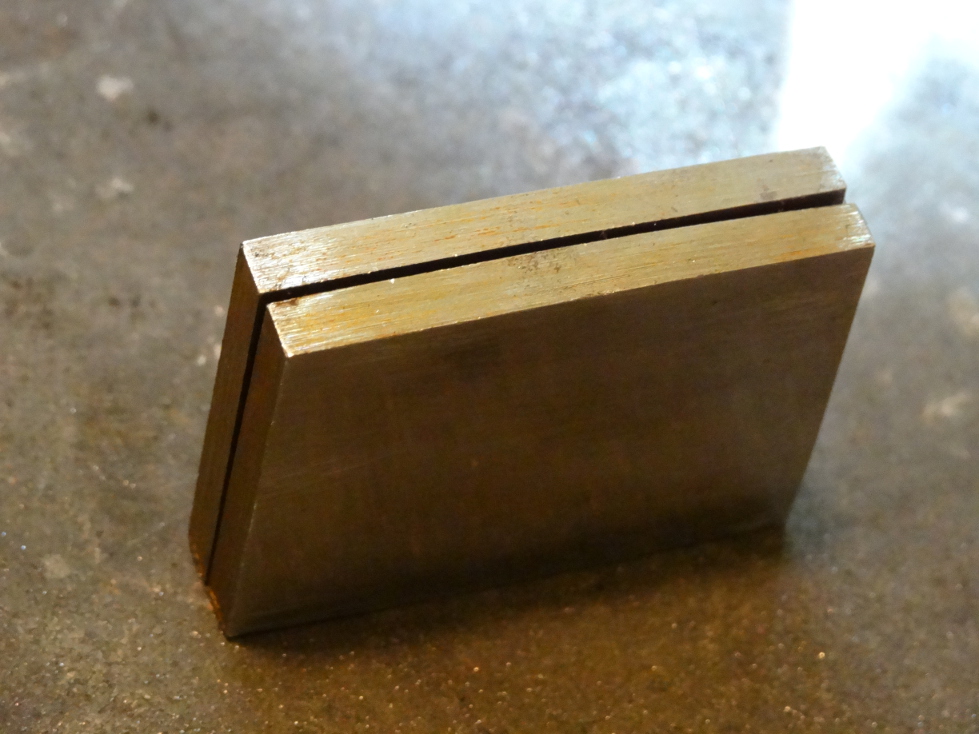

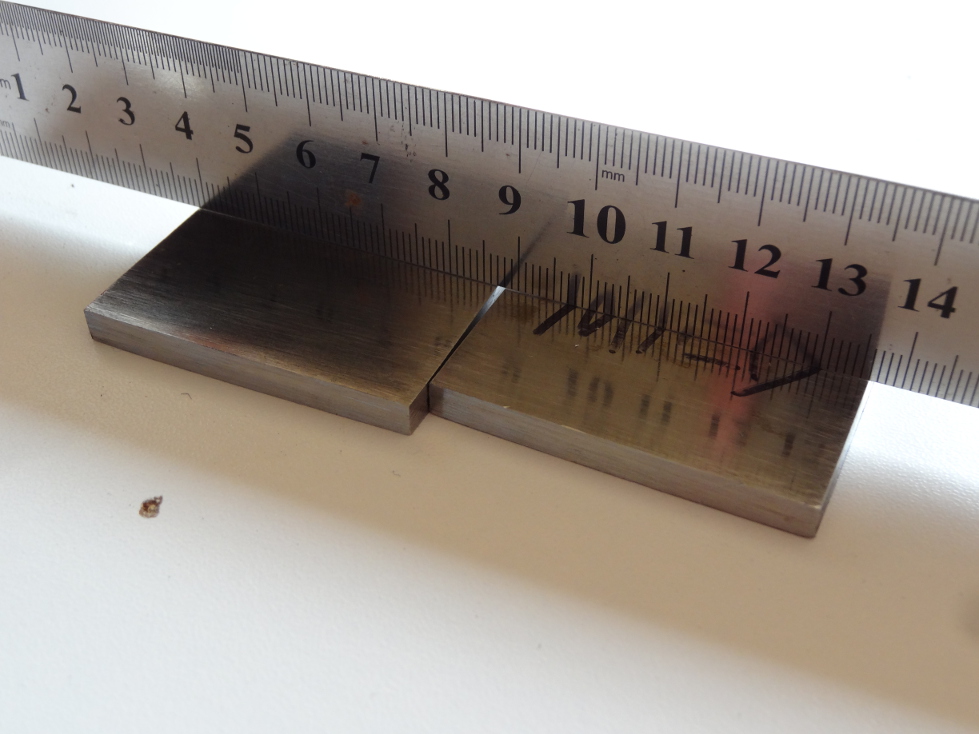

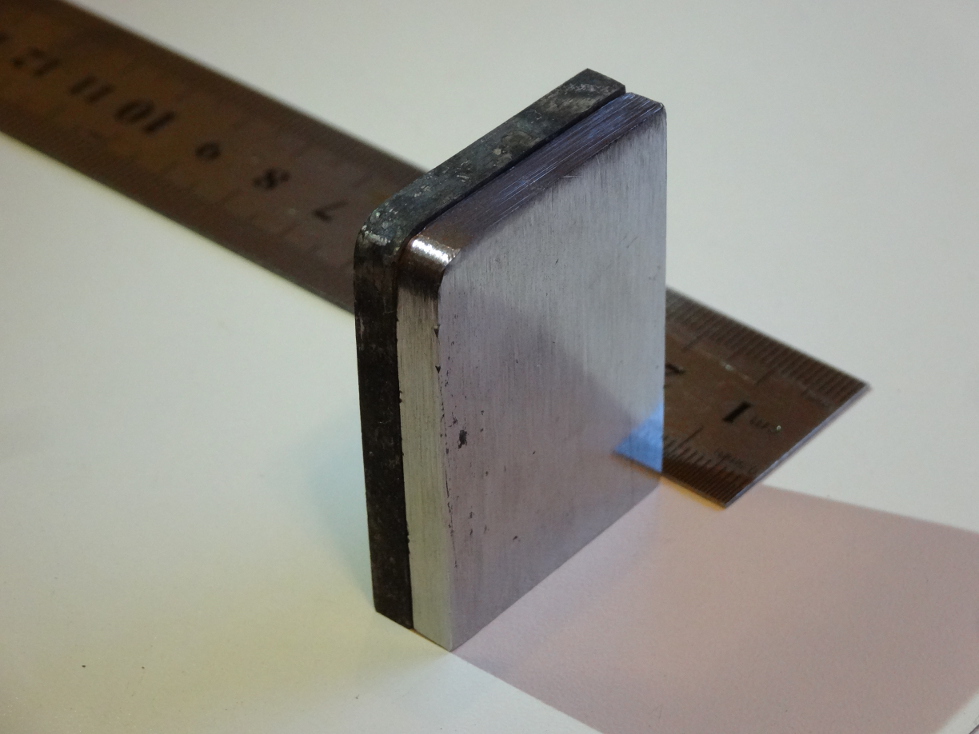

I'm working on my other 'Kippington experiment' now. Gonna use W2 and mild for this one, hopefully I get the quench done before it gets too dark out.