You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Catcheside Cutlery - Works in progress.

- Thread starter WillC

- Start date

Help Support Kitchen Knife Forums:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

Hello Warren, sorry for my lack of reply, I have been having a tough couple of weeks. I got myself an old canon 20d and a 50mm lens, I have it set up on a tripod with a timer.....It makes for some nice surprise shots....Since I have been using the dslr I can't bring myself to use anything else

Lots going on in the workshop, will get some pics up soon.

Lots going on in the workshop, will get some pics up soon.

Hello Warren, sorry for my lack of reply, I have been having a tough couple of weeks. I got myself an old canon 20d and a 50mm lens, I have it set up on a tripod with a timer.....It makes for some nice surprise shots....Since I have been using the dslr I can't bring myself to use anything else

Lots going on in the workshop, will get some pics up soon.

Hi Will, no worries about the lack of quick reply as I know how busy most of the people on here are:thumbsup:

Have you tried doing any long exposure shooting? might look good with the trails of sparks flying about

WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

Im sure Nikon are fab, I went canon as I picked one up at a bargain price and I can borrow my brothers expensive lenses if required. Between the kit lens the 50mm plastic fantastic and a rather nice 60mm macro seems to have it covered for workshop and end product photographs.

I had to have a break from grinding today so I set about forging damascus carving forks and a cheeky little, well quite chunky tasting spoon from stainless....

Soon to be forks, the process for these is to forge to shape, then grind the last of the profiling in as these are damascus and will want to be hand finished and etched....

Now split for the tines, next step will be to separate the them and forge them out... then I will draw the rest from the rest of the lump...

I have been wanting to try a forged tasting spoon for a while, so here is one, my way, forged from 20mm stainless steel.

She is pretty an authoritative spoon I would say, suitable for a sharp clock to the head from senior chef if the flavour does not meet his exacting standards...

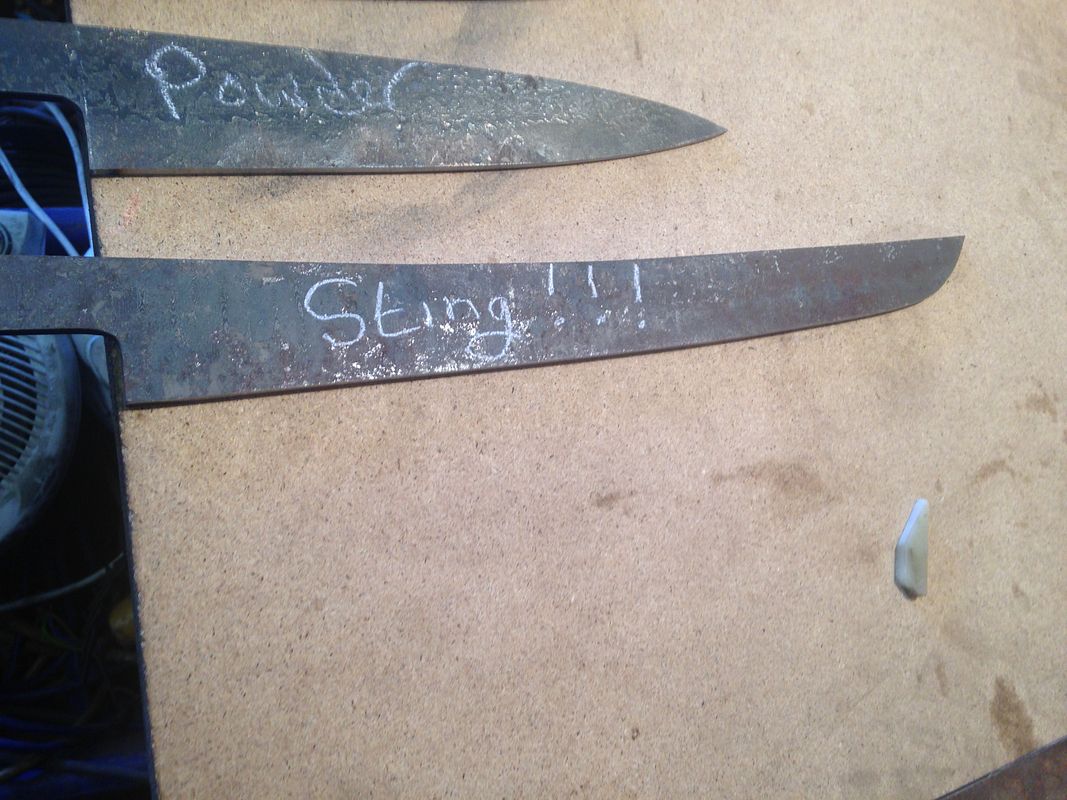

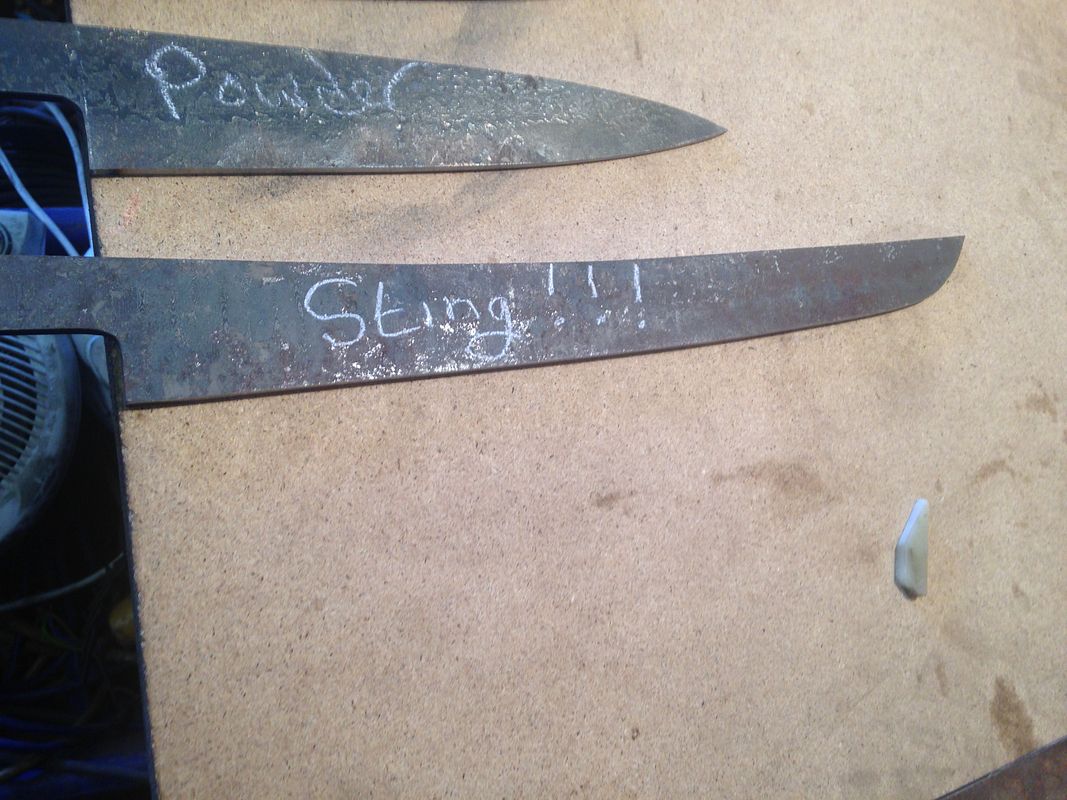

And finally what is in grind process.....lots

Feather damascus.....

This is the slice off the end of the loaf, the pattern will stretch out from here as its forged into blades but just for a taste....

And some others...

I had to have a break from grinding today so I set about forging damascus carving forks and a cheeky little, well quite chunky tasting spoon from stainless....

Soon to be forks, the process for these is to forge to shape, then grind the last of the profiling in as these are damascus and will want to be hand finished and etched....

Now split for the tines, next step will be to separate the them and forge them out... then I will draw the rest from the rest of the lump...

I have been wanting to try a forged tasting spoon for a while, so here is one, my way, forged from 20mm stainless steel.

She is pretty an authoritative spoon I would say, suitable for a sharp clock to the head from senior chef if the flavour does not meet his exacting standards...

And finally what is in grind process.....lots

Feather damascus.....

This is the slice off the end of the loaf, the pattern will stretch out from here as its forged into blades but just for a taste....

And some others...

Mrmnms

Senior Member

- Joined

- Oct 11, 2012

- Messages

- 1,853

- Reaction score

- 7

"She is pretty an authoritative spoon I would say, suitable for a sharp clock to the head from senior chef if the flavour does not meet his exacting standards..." Almost wet my pants Will. Gonna try this at home... fist with a rubber spatula or sponge

Spoon looks like a WINNER. Maybe for a Fall Collection?

Spoon looks like a WINNER. Maybe for a Fall Collection?

WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

This batch are all getting finished off, just the polish and etch on the handles to go, two more Gyuto's to etch too.

Honing the whole bevels after the etch, a great advantage to having the hollows for maintenance.

1500 grit prior to the etch.

Two different feather variations side by side. On both the edge and spine side are different materials. Edge side is double high carbon, very hard yet tough still due to the combination and fineness of the pattern. 62/63hrc Spine side has pure nickel in the mix.

Still got to polish and etch the damascus handle parts.

This shows up the extra shine in the pure nickel, it also etches a bit deeper than the double high carbon mix.

Getting there!

Honing the whole bevels after the etch, a great advantage to having the hollows for maintenance.

1500 grit prior to the etch.

Two different feather variations side by side. On both the edge and spine side are different materials. Edge side is double high carbon, very hard yet tough still due to the combination and fineness of the pattern. 62/63hrc Spine side has pure nickel in the mix.

Still got to polish and etch the damascus handle parts.

This shows up the extra shine in the pure nickel, it also etches a bit deeper than the double high carbon mix.

Getting there!

WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

All the bold pattern knives are to commission. Some of the others will be available as well as some san mai this month. I have to move workshop at the end of the month! So will help with the couple of weeks downtime during the move. To be fair I give my mailing list first priority of any extra knives before they hit the store. You can get on my mailing list here,

http://www.catchesidecutlery.com/shop.html

And you can get an idea of pricing from blade size from my custom order page. Thanks.

http://www.catchesidecutlery.com/shop.html

And you can get an idea of pricing from blade size from my custom order page. Thanks.

icanhaschzbrgr

ill-Known Member

Damn Will! Those aren't kitchen knives, those are work of art!

Stunning look!

I'm seriously considering robbing some bank or selling a kidney in order to get myself a nice damascus Catchside knife

Stunning look!

I'm seriously considering robbing some bank or selling a kidney in order to get myself a nice damascus Catchside knife

That is amazing work.

jimbob

Senior Member

Sweet knives mate. But seriously, i want that spoon..

wellminded1

Senior Member

- Joined

- Mar 13, 2012

- Messages

- 500

- Reaction score

- 1

San mai you say????

WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

San mai I say!

Yes we have progress, after the move, I shuffled around in there for a while, realising I had run out of this and that, and lost this and that. Then my back started playing up, finally all sorted and really happy working in there now.

Anyway a few different things so Ill put them here in general updates.

A couple in san mai. One damascus clad 01 one plain clad.

This is the plain clad before the weld, thats all 01 in the middle, will be a nice high weld line as the customer would like an almost hazy hamon like effect, which is what I will go for on the finish.....

This is the Dammy clad after the weld.

The workshop is actually not unbearably hot despite the heatwave.....it helps that I have this chair to sit for a second.....

With a 2hp forge blower pointed directly at me

So here are these 3 about to be heat treated........ the third is another blade in the powder damascus....

Last week I also made a sort of start for the first composite set in getting the Ladder made and set up. I needed to do a test piece in a simple laminate before using it on a mixture of 6 different damascus billets that will make up each composite blade.......

The press tool...... I've made it for a deep, tight ladder, may not need to be this much, will only be able to tell from the finished test piece....

Here was a test bar in 600 plus layers of double high carbon. I have already ground one side off, but it was like this both sides, and staggered...... You loose half the thickness of the piece to the workshop floor!!!

This is where a big Mill or a surface grinder help the grinding tedium...... I ground the lumps down with a 9" grinding disc by hand then, ripped it down flat with a 36 grit belt on my big horizontal linisher.....

We have left a still rather sizeable blank.....

From which I decided to make a nice big meat slicer....

Blade length 360mm,

She is beefy!! Will get a tad more taper but lots of meat left in, will have a wide double bevel, should look great with the tight ladder.

I played around with the profile a bit, will probably fiddle some more after HT.

And something western style will be happening, but will have to take my time over that..... The main goal for now is to see what the steel looks like then get on with the first set commission.

[

And `i think I settled on the wood for the powder, one of the hardest knives I have chosen wood for for some reason

Cheers all, more updates next week, and any advice on the slicer/carving knife/mini fish sword??welcome. The plan is to use my damascus at normal hardness, 62/63 hrc, take it thin but leave a little of a wider steeper. edge bevel than usual. I know these steels are super tough together even at this hardness, together they make a steel capable of greater stability at a higher hardness, which is why I love the combo......here I have to allow for being used against bones etc, a slightly wider bevel I think will allow for that......will see.... Will be as hard and thin at the edge as I dare go given the use..... To be honest I feel if the HT is right I am more worried about chips from against the fork. But if I make the fork softer, and give it a slightly more robust edge geometry you will just have notches in your fork instead

Would be very invested to hear on what your all out carvers are like, hardness, and the geometry you like to maintain for working around large boned joints and fish.

Yes we have progress, after the move, I shuffled around in there for a while, realising I had run out of this and that, and lost this and that. Then my back started playing up, finally all sorted and really happy working in there now.

Anyway a few different things so Ill put them here in general updates.

A couple in san mai. One damascus clad 01 one plain clad.

This is the plain clad before the weld, thats all 01 in the middle, will be a nice high weld line as the customer would like an almost hazy hamon like effect, which is what I will go for on the finish.....

This is the Dammy clad after the weld.

The workshop is actually not unbearably hot despite the heatwave.....it helps that I have this chair to sit for a second.....

With a 2hp forge blower pointed directly at me

So here are these 3 about to be heat treated........ the third is another blade in the powder damascus....

Last week I also made a sort of start for the first composite set in getting the Ladder made and set up. I needed to do a test piece in a simple laminate before using it on a mixture of 6 different damascus billets that will make up each composite blade.......

The press tool...... I've made it for a deep, tight ladder, may not need to be this much, will only be able to tell from the finished test piece....

Here was a test bar in 600 plus layers of double high carbon. I have already ground one side off, but it was like this both sides, and staggered...... You loose half the thickness of the piece to the workshop floor!!!

This is where a big Mill or a surface grinder help the grinding tedium...... I ground the lumps down with a 9" grinding disc by hand then, ripped it down flat with a 36 grit belt on my big horizontal linisher.....

We have left a still rather sizeable blank.....

From which I decided to make a nice big meat slicer....

Blade length 360mm,

She is beefy!! Will get a tad more taper but lots of meat left in, will have a wide double bevel, should look great with the tight ladder.

I played around with the profile a bit, will probably fiddle some more after HT.

And something western style will be happening, but will have to take my time over that..... The main goal for now is to see what the steel looks like then get on with the first set commission.

[

And `i think I settled on the wood for the powder, one of the hardest knives I have chosen wood for for some reason

Cheers all, more updates next week, and any advice on the slicer/carving knife/mini fish sword??welcome. The plan is to use my damascus at normal hardness, 62/63 hrc, take it thin but leave a little of a wider steeper. edge bevel than usual. I know these steels are super tough together even at this hardness, together they make a steel capable of greater stability at a higher hardness, which is why I love the combo......here I have to allow for being used against bones etc, a slightly wider bevel I think will allow for that......will see.... Will be as hard and thin at the edge as I dare go given the use..... To be honest I feel if the HT is right I am more worried about chips from against the fork. But if I make the fork softer, and give it a slightly more robust edge geometry you will just have notches in your fork instead

Would be very invested to hear on what your all out carvers are like, hardness, and the geometry you like to maintain for working around large boned joints and fish.

Burl Source

Weird Wood Pusher

- Joined

- Jun 13, 2011

- Messages

- 4,340

- Reaction score

- 7

Congratulations on getting things going in the new shop.

I can't wait to see how these turn out.

Looking good so far.

I can't wait to see how these turn out.

Looking good so far.

wellminded1

Senior Member

- Joined

- Mar 13, 2012

- Messages

- 500

- Reaction score

- 1

Amazing.

WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

I have started to think about the western construction on the slicer, despite it being a bit of a distraction. :spankarse:

I found a chunk of damascus for the bolster to forge down, tried some colour case hardening on it, ( hot bluing) Im going to try and use this treatment in this Slicer handle to test it out. Its a good semi permanent finish if done right, it can be buffed to a high finish like on case hardened shotgun parts.

I had to grind the slicer to check my ladder dies are going to be ok for the sets.

Its double bevel, some nice taper now, from 5mm down to about 2.8mm before it tapers down with the bevel....

Im conferring with a meat expert......But this will be like a heavy Suji, slicing Proteins in larger sizes. Or a show off sunday dinner:knife: As such I'm grinding it thin at the edge.....and have taken the temper a touch over what these steels can be down to around 61/62. These are super tough together at around this hardness.

After the etch, Im pretty sure I want to fully grind/convex it the rest of the way, make the most of that pattern and shed a tad more weight......Just a quick etch after a belt finish....

The ladder dies were a success though, I'm pleased with that tight even ladder.............

360mm heel to tip.

Next to grind these san mai having completed all the temper cycles on those while messing about with handle parts and grinding.

I found a chunk of damascus for the bolster to forge down, tried some colour case hardening on it, ( hot bluing) Im going to try and use this treatment in this Slicer handle to test it out. Its a good semi permanent finish if done right, it can be buffed to a high finish like on case hardened shotgun parts.

I had to grind the slicer to check my ladder dies are going to be ok for the sets.

Its double bevel, some nice taper now, from 5mm down to about 2.8mm before it tapers down with the bevel....

Im conferring with a meat expert......But this will be like a heavy Suji, slicing Proteins in larger sizes. Or a show off sunday dinner:knife: As such I'm grinding it thin at the edge.....and have taken the temper a touch over what these steels can be down to around 61/62. These are super tough together at around this hardness.

After the etch, Im pretty sure I want to fully grind/convex it the rest of the way, make the most of that pattern and shed a tad more weight......Just a quick etch after a belt finish....

The ladder dies were a success though, I'm pleased with that tight even ladder.............

360mm heel to tip.

Next to grind these san mai having completed all the temper cycles on those while messing about with handle parts and grinding.

erikz

Senior Member

- Joined

- Oct 7, 2013

- Messages

- 744

- Reaction score

- 1

The Damascus looks beautifully executed Will.

**

- Joined

- May 1, 2012

- Messages

- 4,139

- Reaction score

- 10,785

Stunning already!

WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

Made a little progress on the 360mm Slicer today whilst damascus was heat cycling and while waiting for various supplies......

Grind completed. I decided to fully grind it, glad I did it will work best with the pattern and it is a heavy knife, needed the extra taper and weight loss that a full grind provides......

Its just over 5mm thick spine over heel, to about 3mm around 50mm from the tip, from there it tapers down to a thin but convexly robust tip. I have tried it on a joint of meat and it works very nicely I think.

Spine is rounded now, everything down to about 200 grit, so the hard graft done, just finishing to go.

Kinda gives an idea of the taper, but distorted by the camera.....

Next I've been mulling over handle construction given that I am going to be surface treating the Bolster after final finish so will need to fit exact.....

So I've been machining a cunning bolt arrangement for the back of the handle...... will thread over a threaded bar welded to the tang. You might not quite see how this is going to work at the moment but all will become clear....

Next to glue on the angle end cap and make a slightly different sort of jig to rough cut the handle shape......

But for now back to damascus......

Grind completed. I decided to fully grind it, glad I did it will work best with the pattern and it is a heavy knife, needed the extra taper and weight loss that a full grind provides......

Its just over 5mm thick spine over heel, to about 3mm around 50mm from the tip, from there it tapers down to a thin but convexly robust tip. I have tried it on a joint of meat and it works very nicely I think.

Spine is rounded now, everything down to about 200 grit, so the hard graft done, just finishing to go.

Kinda gives an idea of the taper, but distorted by the camera.....

Next I've been mulling over handle construction given that I am going to be surface treating the Bolster after final finish so will need to fit exact.....

So I've been machining a cunning bolt arrangement for the back of the handle...... will thread over a threaded bar welded to the tang. You might not quite see how this is going to work at the moment but all will become clear....

Next to glue on the angle end cap and make a slightly different sort of jig to rough cut the handle shape......

But for now back to damascus......