gemeengoed

Member

- Joined

- Oct 15, 2015

- Messages

- 19

- Reaction score

- 0

Hi guys,

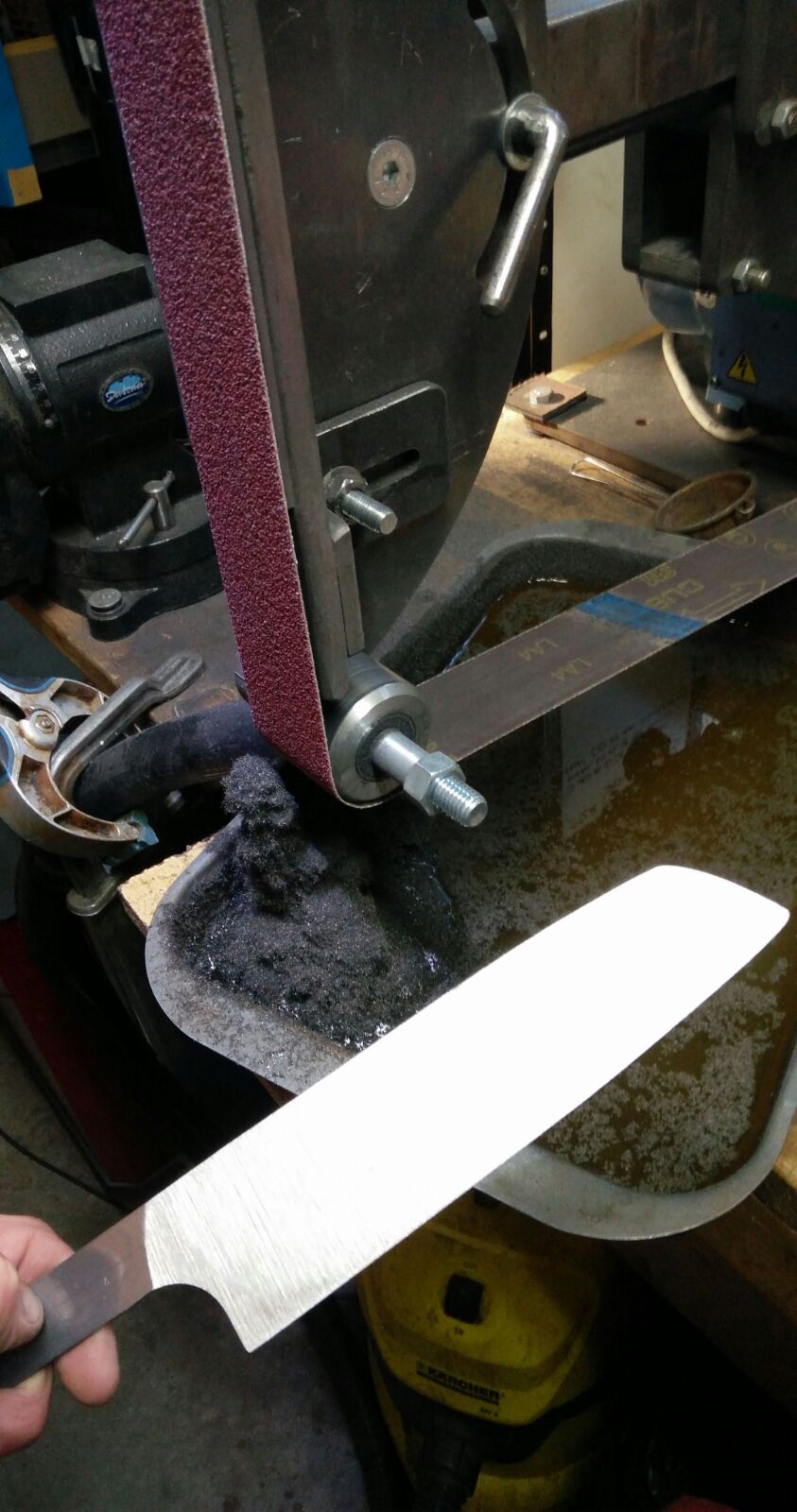

I just heat treated my first 3 chef's knives in my new oven and am wondering about the colors. It looks fantastic but are these knives heat treated properly?

The oven was set to ramp to 650 degrees Celsius, hang there for about an hour, and then up to 1030 degrees Celsius for about 10 minutes after i quenched them between steel plates.

https://flic.kr/p/BKmrfd

cheers,

-sander

I just heat treated my first 3 chef's knives in my new oven and am wondering about the colors. It looks fantastic but are these knives heat treated properly?

The oven was set to ramp to 650 degrees Celsius, hang there for about an hour, and then up to 1030 degrees Celsius for about 10 minutes after i quenched them between steel plates.

https://flic.kr/p/BKmrfd

cheers,

-sander