milkbaby

Well-Known Doofus

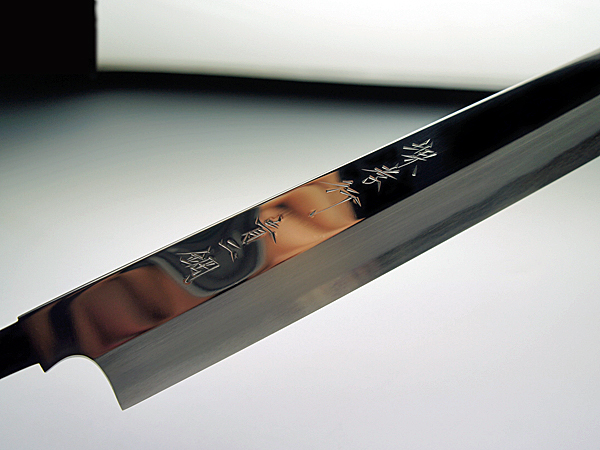

I was goofing off looking at knives and saw this pic of a Shiraki forged honyaki from K&S:

As you can see from the photo, it's nicely reflective and shiny but not a "true mirror" finish. I want to finish some monosteel knives with sandpaper and have gone up to consistent 1500 sandpaper grit finish which gave a nice reflective and shiny surface which also is not a true mirror.

So my question is about how high a finish you can get with typical sandpaper? I have 1000, 1200, 1500, 2000, 2500, 3000 grit but any higher it seems I will have to try micromesh pads?

As you can see from the photo, it's nicely reflective and shiny but not a "true mirror" finish. I want to finish some monosteel knives with sandpaper and have gone up to consistent 1500 sandpaper grit finish which gave a nice reflective and shiny surface which also is not a true mirror.

So my question is about how high a finish you can get with typical sandpaper? I have 1000, 1200, 1500, 2000, 2500, 3000 grit but any higher it seems I will have to try micromesh pads?

Last edited: