Knife2meatu

Senior Member

[...] using SP 120 :/ so many trips to refresh the stone.

What are thinning that your SP120 needs refreshing? Oh wait, I'm thinking Shapton Pro, but perhaps you meant Sigma Power?

[...] using SP 120 :/ so many trips to refresh the stone.

Also many guidelines allude to possible cancer concerns even just by being in contact with SiC powder,

SiC powder is probably less expensive, but reading this makes me wonder if after flattening, would using another flat stone of same grit against the flattened one bring it back to prime?i dont actually have the naniwa/chosera but i have had the 500 glass for several years and i noticed that when it was brand new it cut like crazy. and then after the first flattening it cuts maybe half as fast. but finer.

same thing but even worse with the glass 220 and pro 220.

so these stones really need to be flattened and resurfaced with loose grit SiC powder on glass plates. only then will you get the speed back. otherwise the 220 behaves likes a quite fast 500. and the 500 like a slightly faster 1k. when i reality they are at the very least twice as fast.

so with stones under 1k, especially harder stones, its very important to get the surface roughness right, because this is basically whats doing the actual cutting, not the grit number.

a shapton pro 220 will eventually assume the really agressive surface condition if you just work it and leave the slurry on there. maybe takes 10 minutes.

but after 10 minutes its time for flattening since the stone dishes. and if you do this with diamonds then youre back to square one again. i only have the 220 glass and pro and no other really coarse ones (except diamonds), but i guess its the same with all of them. loose grit...

I have the same exact experience. Flattening plates or same grit SiC wont refresh the surface. It just keeps feeling mellow. 80-90 SiC does the trick for me.using even the same grit stone on a coarse stone will not bring it back to original state imo. it will become way way too fine.

you need 50-60-80 grit powder to get a 220 going well imo. the 220 will still work when flattened with a diamond stone but it will be ultra slow compared to new.

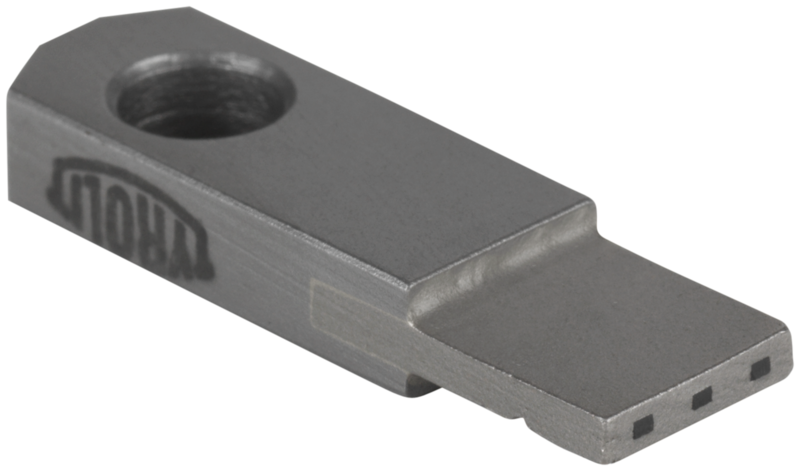

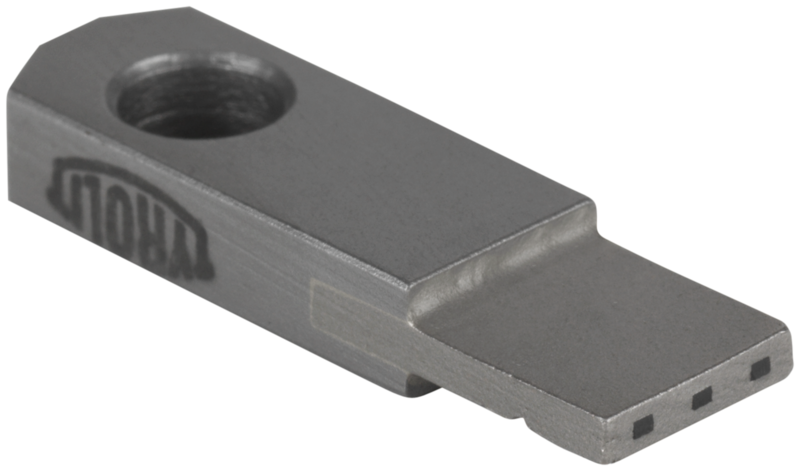

Can't find it online, can you post a link?My buddy Francis from Knifewear told me to use this thing to refresh a rough stone. it works great and it's cheap if it's mess up.

SiC powder is probably less expensive, but reading this makes me wonder if after flattening, would using another flat stone of same grit against the flattened one bring it back to prime?

Edited to add: Perhaps with coarse stones there is something to consider flattening between 3 identical stones. Use each and then flatten between them to a workable flatness on all 3?

Thoughts?

D.

Can't find it online, can you post a link?

the reason I use it is that it is 36 grit that could scratch a surface of the rough whetstone and help it cut again. It cost CAD $13 at Lee Valley and probably less in Amazon. I have a 200 grit SC stone that starts to clog up, and refresh it with this one and viola!! it starts to cut perfectly again.its a truing/dressing tool for grinding wheels.

https://duckduckgo.com/?q=Diamond+grinding+wheel+dressing+tool&t=hk&iar=images&iax=images&ia=images

now these are actually the not so good ones for truing grinding wheels. you want ones with maybe 5-20 longer diamond sticks embedded in steel. they last longer. they are called multipoint dressing/truing tools.

the plated ones will be better for stones obviously since the other ones below would most likely be almost useless.

This is my philosophy. I use SiC on granite of they get really bad but mostly I just rub stones together. I group them into categories. I have about a half dozen 5$ Chinese diamond plates. They are rarely used and I've never purchased an atoma. I just segregate my stones by category and I have at least 3 in each category so that by rotating them I keep them all relatively flat. Synthetic oil stones with other synthetic oil stones, Japanese soakers with other soakers, Shapton Glass and pro with each other. I have tomo nagura for my finishers. Jasper to clean and condition my jasper. A little piece of surgical black ark to treat my translucent Ark. Coticules with coticules, etc. With some I use the slurry. But for other it's just to keep the surface fresh and clean and to aid some in extending the period between flattenings.

Here's my Ark with Ark nagura.

View attachment 82317

Enter your email address to join: