Angle doesn't matter toooo much. Here's a flowmap for example:

1. What grit

A. Edge completely rounded? --> start at coarse stone 220-500 grit

B. Edge just dull? --> start at 1000 grit

2. What angle

Look at the angle on the knife and match it if you want the same angle. Rock the knife edge at an angle gently on the stone and feel which angle feels slightly more secure. This is easiest with larger bevels sizes -- which is too thick for normal use. Look at the bevel to see old scratch pattern from previous edge. Sharpen a little with angle you choose and look

A. If new scratch pattern is above the old bevels, then lower the angle until the new scratch pattern lines up on top of the old scratch pattern.

B. If the new scratch pattern is closer to the edge, and doesn't cover the old scratch pattern completely, lower the angle until the centers line up, or the new scratch pattern on the edge bevel covers the old one.

3. Sharpen both sides until a small consistent burr, using outlined process.

4. (Optional) Does the knife cut with the amount of resistance and stability you want for the task?

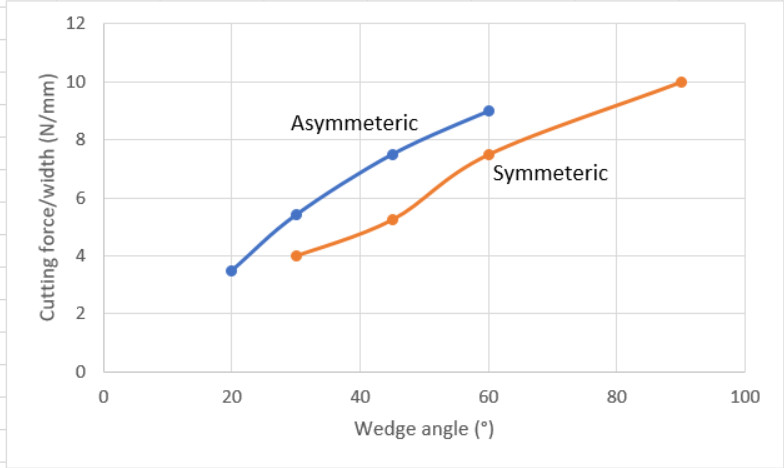

A. Too much force required. Lower the sharpening angle and thin behind the edge so there's less cutting force needed.

B. Too easy to cut, it feel fragile. Increase the edge angle

Faq:

1. Is it bad if I have too high of an angle?

The knife reprofiled faster, loses height faster, gets thicker cross sectional geometry (less chipping, more resistance in food). This can be good to change the profile, increase toughness, remove chips. All sharpening reduces the overall life of the knife, but knives need to be sharp to work, so try to strike a compromise on how much to sharpen.

2. Is it bad if I have too low of an angle?

A lower angle thins the knife and makes it easier to move through food. If it scratches the blade face much higher than the edge bevel, thats usually too low of an angle. A little bit above the edge is fine. You can continue it to set a new lower edge angle. Or sharpen it without creating a burr, which thins the knife and makes cutting smooth without changing the edge angle. Thinning lets the knife cut well with less force, so it's a good thing to be able to do.

3. Is it bad to not have a precise angle?

Not the biggest issue. Just feel that the edge everywhere is sharp. Of course if you want better and better edge results, being able to hold a consistent angle is important. But being able to hold a 18 vs 19 degree angle doesn't matter too much, compared to a generally high or low angle for toughness or sharpness. Or more importantly, making a clean apex at whatever angle you choose, which you can test with paper, hair, finger feeling, etc, and inspect visually or even microscopically

For pocket knives overall geometry doesn't seem to be as vital, but same applies.