Barry's Knives

Well-Known Member

In sword sharpening it seems common practice to use convex or domed whetstones. Does anyone have any experience using these? And can anyone explain why its beneficial?

As far as I can tell they are shaped that way purposely. Whetstones tend to dish when used, not become convexAren't they just using their stones that way because they don't bother to flatten their stone?

Have you ever gotten errant scratches from the raised edge of a dished stone? If they didn't convex the stone, they'd have to flatten it every few minutes. The only real advantage to a flat stone is to simplify the geometry for amateurs who struggle with finding the proper angle. If this is your life and you're being paid > $10K to achieve a perfect mirror finish over the length of a full sword, a flat stone causes more problems than it solves.

And from my experience and talks with sword polishers that’s exactly what this is aboutAs far as I know, they polish thousands of tiny sections and blend them with finger stones. So my best guess at the moment is that the curved stone contacts the convex edge at very precise points.

... But I suppose that if all their bevels are convex, the flatness wouldn’t be an advantage ...

I'm guessing its nugui, typically a mix of compounds containing aluminium oxideSeems to me that a convexed stone helps to prevent faceting and helps to blend all of the many sharpening angles used together, a muddy stone probably also helps.

What is the material that is being painted on in the last video?

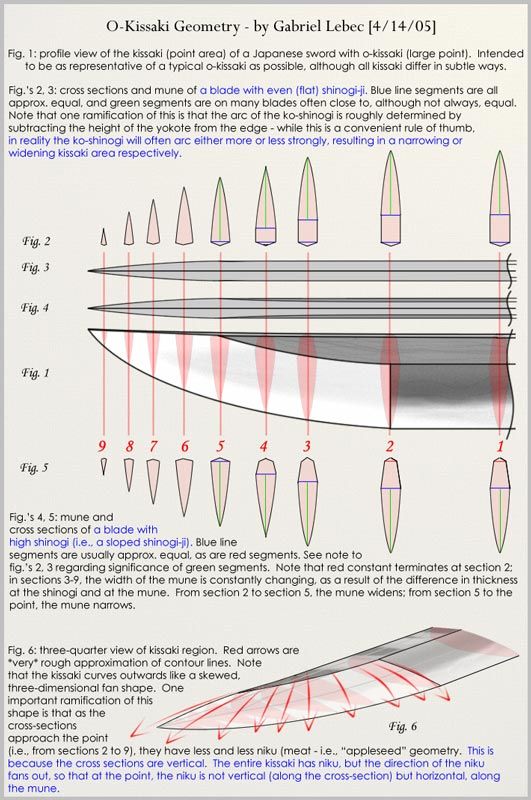

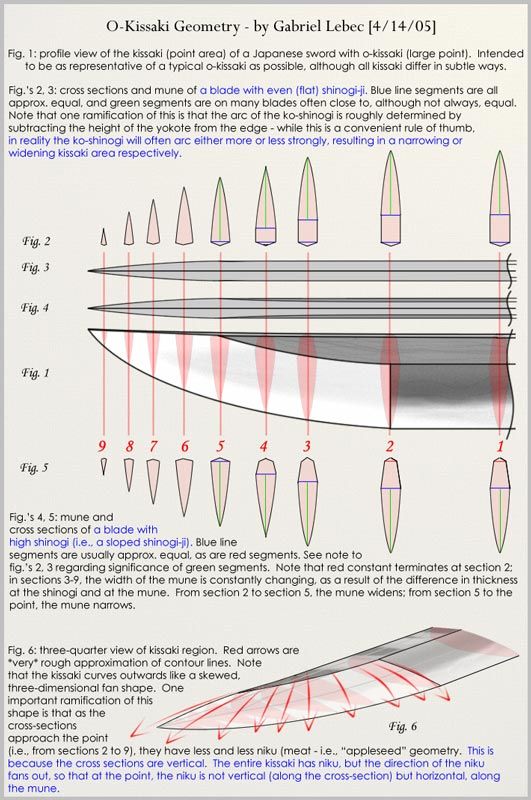

Exactly! Compared to a kitchen knife, a katana's cross section is highly convex. If you imagine the blade road of a standard deba approximated as a section of a cone - a surface with single curvature* - then the blade road of a katana would be approximated as a section of a sphere. Because we're not robots, freehand sharpening a katana on a flat stone would give a very slight advantage, while increasing the risk of scuffing on the stone's edge. That trade-off makes total sense for a relatively short kitchen knife that's sharpened for daily use, but not a katana with double curvature that's given a mirror polish once a decade entirely for aesthetics.

*Not really though. The blade road on a single bevel knife is very slightly convex, but an order of magnitude less than a katana. For the sake of argument we can approximate it as a surface with single curvature, because when freehand sharpening on a flattened stone the entire blade road from edge to shinogi line contacts the stone on each stroke - again, cause we're not robots.

Here's some cool stuff:

What is the material that is being painted on in the last video?

Is this to exert more pressure on precise parts of the blade to essentially 'sculpt' it more accurately? Is it more common on lower grit stones?Sword polishing is more like sculpting metal so they need to adapt stones to some blade shapes very different from kitchen knives.

For example, with my Tamahagane blade from Yasha Yukawa I had to give a slightly convex shape to my stones in order to get the job done.

For kitchen knives I don't see many advantages to work on unflattened stones.

Enter your email address to join: