Sukenari AS, ZDP-189 and HAP-40 lines are some I can think of off the top of my head.I'm not generalizing to all people, I'm just saying, for my purposes, I like having a knife with a hard Japanese steel, for edge retention purposes, as opposed to, say, a Wuesthoff or Zwilling. I use soft wood cutting boards specifically to save the edge (pine, red cedar, redwood). My Tojiro DPs and the Randy Haas have performed amazingly well over 10 years of light use.

Yes, according to my notes at the time, the Tojiro DPs are 60-61, the Randy Haas, also 60-61. Never had to use a rod, but I did re-sharpen them all at least once, maybe twice.

That's astonishing to me that you call 62-65 'medium hard'. You mean to say there are knives out there that are harder than 65? YIKES!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

edge retention after sharpening

- Thread starter Goorackerelite

- Start date

Help Support Kitchen Knife Forums:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Alloyed steels. They end up harder but the alloy is keyThanks for the links! I look forward to the deep dive

Interesting that the Germans have finally figured out that a higher HRC is a good thing...

Carbon also.Alloyed steels. They end up harder but the alloy is key

When I changed to shaptons it solved this problem for me, I get better each time. I finish on a little natural and then polish it back up every ten days or so with diminishing returns each time and then after about 6 to 9 weeks later it’s time to go thru the progression again. This is thru primarily home use. (I also hone, however you need proper technique on that for it to be effective and not destroy your edge or even chip your knife).

I think it has to do with expectations sometimes. I compare how long my edge lasted to the knife’s OTB and if it’s comparable I know I’m doing a good job.

Also what steel are you using? I find white 2 to lose its edge way quicker than blues. But it’s way easier to polish/hone. I’ve literally honed my white 2 back to passing sharpness tests after it couldn’t cut computer paper.

I think it has to do with expectations sometimes. I compare how long my edge lasted to the knife’s OTB and if it’s comparable I know I’m doing a good job.

Also what steel are you using? I find white 2 to lose its edge way quicker than blues. But it’s way easier to polish/hone. I’ve literally honed my white 2 back to passing sharpness tests after it couldn’t cut computer paper.

Kawa

Senior Member

When I changed to shaptons it solved this problem for me, I get better each time. I finish on a little natural and then polish it back up every ten days or so with diminishing returns each time and then after about 6 to 9 weeks later it’s time to go thru the progression again. This is thru primarily home use. (I also hone, however you need proper technique on that for it to be effective and not destroy your edge or even chip your knife).

I think it has to do with expectations sometimes. I compare how long my edge lasted to the knife’s OTB and if it’s comparable I know I’m doing a good job.

Also what steel are you using? I find white 2 to lose its edge way quicker than blues. But it’s way easier to polish/hone. I’ve literally honed my white 2 back to passing sharpness tests after it couldn’t cut computer paper.

I don't know if this is a meaningfull reference. From what i've read around here, the OOTB edge can be worse then a fresh, new edge. OOTB edges are often finished with powertools (a belt grinder goes also under the name 'hand finished', but we often think of wetstones when hearing hand finished). Sometimes the edge gets too hot and changes the effect of the original heat treatment. A OOTB edge might therefore be more chippy or does wear faster then after a sharpening (or 2).

I'm not generalizing to all people, I'm just saying, for my purposes, I like having a knife with a hard Japanese steel, for edge retention purposes, as opposed to, say, a Wuesthoff or Zwilling. I use soft wood cutting boards specifically to save the edge (pine, red cedar, redwood). My Tojiro DPs and the Randy Haas have performed amazingly well over 10 years of light use.

Edges can fail for a number of reasons:

1) The edge can roll over. This is the predominant mode of failure in softer steeled knives. The likelihood of this happening dependes on the hardness of the steel and the geometry just behind the edge (i.e.: the amount of steel supporting the edge. i.e.: the angle that the edge bevel is sharpened at).

2) The edge can chip. This is more likely with very hard, brittle steels, especially those sharpened to a very acute edge. Many of these steels are limited in the acuity of their edge angle by having a high carbide volume anyway.

3) The apex of the edge can be gradually abraded by food and the chopping board. @Larrin 's cardstock experiments have demonstrated that this is slower with an ACUTE edge angle. Hardness probably contributes somewhat to abrasion resistance but carbide volume (which in itself limits edge acuity) is much more important.

So in general, there are 3 strategies that can be used to maximise edge retention:

1) Soft steels in thick-edged (and thick behind the edge) knives. The edge fails by rolling and can be realigned with a "sharpening steel". These steels are often abrasion resistant and tough. Repeated realigning of the edge weakens the steel near the edge (work hardening/embrittlement, like a paperclip bent backwards and forwards over and over), so eventually the embrittled edge will chip. This tends to produce less well performing knives with the lowest overall edge retention but the most abuse resitance (which is why it is the stategy selected for mainstream knives).

2) Moderatelly hard steels (HRC 61-63?) made of simple steels with acute edges. Failure mode is by abrasion resistance as they generally don't roll over and are tough enough to not chip easily (depending on edge angle). This strategy produces the sharpest edges with moderate edge retention.

3) Highly alloyed hard steels (HRC 60-67): The more highly alloyed the steel, the more abrasion resistant but... the less acute an edge they can take (due to carbide volume causing carbide pull-out). These knives have a lower ultimate sharpness but generally longer edge retention than strategy 2. The harder these steels get, the more brittle they are and the more prone to the edge chipping. This strategy produces fairly sharp edges with generally the longest edge retention.

This is obviously a continuum And many knives will have a foot in two camps.

So hardness does affect edge retention, but the how is complex and it is nowhere near as straightforward as "harder is better".

Last edited:

- Joined

- May 3, 2011

- Messages

- 9,828

- Reaction score

- 4,547

A factory edge isn't necessarily meant to be used as such. A too fine an edge allows you to put your own on it with a few strokes only, but wouldn't survive the first board contact. If you get a Honesuki with an inclusive angle of 12° don't believe you're dealing with a miraculous steel. Rather get your stones.

Thanks for the summary! Makes a lot of sense to me, and makes me even more satisfied with my knives, which are 60-61 HRC, apparently and have held their edges for far longer than I expected them to. I wonder about the very hard alloyed steels. They must be hard to sharpen. I mean, they must require a lot of elbow grease and numerous passes, no?Edges can fail for a number of reasons:

1) The edge can roll over. This is the predominant mode of failure in softer st<snip>

Increased wear resistance... as @inferno so aptly put a couple of times on different occasions it’s a tradeoff of time on the stones vs. time the edge endures. That being said, if you don’t use a lot of slicing motion, and don’t cut into the cutting board any chance you get, there’s not a lot of need for wear resistance and no problem whatsoever for a simple carbon to retain it’s edge for some time.

Yes and no. Regular water stones would choke or be really slow. Diamond stones don't care about the alloy or hardness.Thanks for the summary! Makes a lot of sense to me, and makes me even more satisfied with my knives, which are 60-61 HRC, apparently and have held their edges for far longer than I expected them to. I wonder about the very hard alloyed steels. They must be hard to sharpen. I mean, they must require a lot of elbow grease and numerous passes, no?

If you use the wrong tools for the job, yes. Today we have quite good different types of bonds for diamond and cbn (unfortunately cbn still really expensive).Thanks for the summary! Makes a lot of sense to me, and makes me even more satisfied with my knives, which are 60-61 HRC, apparently and have held their edges for far longer than I expected them to. I wonder about the very hard alloyed steels. They must be hard to sharpen. I mean, they must require a lot of elbow grease and numerous passes, no?

- Joined

- May 3, 2011

- Messages

- 9,828

- Reaction score

- 4,547

Wear resistance is a factor in edge retention, but no guarantee. Many crappy soft stainless have a spectacular wear resistance but a poor edge retention due to the lack of edge stability resulting from large, poorly distributed or clustering chromium carbides. More advanced, hard stainless have a much better edge retention but do not take or hold the finest edges.Increased wear resistance... as @inferno so aptly put a couple of times on different occasions it’s a tradeoff of time on the stones vs. time the edge endures. That being said, if you don’t use a lot of slicing motion, and don’t cut into the cutting board any chance you get, there’s not a lot of need for wear resistance and no problem whatsoever for a simple carbon to retain it’s edge for some time.

Thanks for the summary! Makes a lot of sense to me, and makes me even more satisfied with my knives, which are 60-61 HRC, apparently and have held their edges for far longer than I expected them to. I wonder about the very hard alloyed steels. They must be hard to sharpen. I mean, they must require a lot of elbow grease and numerous passes, no?

No problem.

I should point out that your Tojiros (VG10) are actually fairly highly alloyed steels, even if their hardness is moderate (62ish IIRC). They are more in group 3 than group 2. Remember that it's not only the hardness but also the carbide volume (degree of alloyimg elements) that's important. So they won't take a super acute edge (but will take a more acute edge than a Wustoff) but will have a decent edge retention. The other issue with some highly alloyed steels (especially VG10 ) is that they require a bit more effort to fully deburr (says the guy who has never actually sharpened VG10

A lot of the more highly alloyed steels (especially PM steels like SG2/R2 SRS15, HAP40 and even ZDP) are a little more difficult to grind, but not that much more. IME, the difficulty lies more in the deburring than the sharpening.

There are certainly some steels that are truly difficulcult to grind, but you don't often see them in kitchen knives (Niolox perhaps being the exception).

Last edited:

- Joined

- May 3, 2011

- Messages

- 9,828

- Reaction score

- 4,547

Please note the somewhat bizarre dulling curve with VG-10: fresh from the stones, sharp like hell. Dulling very quickly to a moderate level of sharpness that will be sufficient in everyday Western cuisine where it stays almost forever.

I’ve agonized over edge retention for several years, it’s a riddle I don’t think I can solve. As sharpeners all we can do is ensure that the edge is clean, thin behind the edge and sharpened an an angle appropriate for the steel. Finishing grit seems to play a role but I’m ignorant of the science behind that. I rarely finish a soft knife finer than 1.5-2k but again, it’s influence on edge retention is a mystery to me personally. I no longer fret about it because once the knife is out of my hands it often falls prey to poor steeling technique, inappropriate storage, slamming the edge on a hard cutting board, using the edge to scrape food off that board. I do what I can with every knife and make sure I educate folks on their role in edge retention. I manage expectations and just do my part.

Oh yes this a good point, only works with knives with a great ootb edge from a great sharpener I’m sorry I should’ve said that...I don't know if this is a meaningfull reference. From what i've read around here, the OOTB edge can be worse then a fresh, new edge. OOTB edges are often finished with powertools (a belt grinder goes also under the name 'hand finished', but we often think of wetstones when hearing hand finished). Sometimes the edge gets too hot and changes the effect of the original heat treatment. A OOTB edge might therefore be more chippy or does wear faster then after a sharpening (or 2).

Kawa

Senior Member

I’ve agonized over edge retention for several years, it’s a riddle I don’t think I can solve. As sharpeners all we can do is ensure that the edge is clean, thin behind the edge and sharpened an an angle appropriate for the steel. Finishing grit seems to play a role but I’m ignorant of the science behind that. I rarely finish a soft knife finer than 1.5-2k but again, it’s influence on edge retention is a mystery to me personally. I no longer fret about it because once the knife is out of my hands it often falls prey to poor steeling technique, inappropriate storage, slamming the edge on a hard cutting board, using the edge to scrape food off that board. I do what I can with every knife and make sure I educate folks on their role in edge retention. I manage expectations and just do my part.

Last week I returned a knife to a friend of mine, explaining some basis things on how to keep it sharp for as long as possible: no dishwasher, not in the drawer etc...

His wife came home and before I could protest she was like: 'ah great, the knife is back. The kitchen machine broke down this afternoon and I want to make a cake with a bottom of scrumbled nuts. Glad I can use the knife now!'

but but but but......

Before I could even respond she started chopping and smashing the nuts and this went on for about an hour...

I can imagine you attempting to hold a discussion with your friend and cringing every few « snap, crack and ziiiing »

Did they still have the shells on? Rock-walking-scrape-chop?Last week I returned a knife to a friend of mine, explaining some basis things on how to keep it sharp for as long as possible: no dishwasher, not in the drawer etc...

His wife came home and before I could protest she was like: 'ah great, the knife is back. The kitchen machine broke down this afternoon and I want to make a cake with a bottom of scrumbled nuts. Glad I can use the knife now!'

but but but but......

Before I could even respond she started chopping and smashing the nuts and this went on for about an hour...

Kawa

Senior Member

I can imagine you attempting to hold a discussion with your friend and cringing every few « snap, crack and ziiiing »

I took out my hearing devices (I really wear them) and that solved that problem

Kawa

Senior Member

Did they still have the shells on? Rock-walking-scrape-chop?

Don't know, I was afraid to go over and look, knowing I can't resist to comment on the abuse in her territory

If it’s a middle of the road knife I’d be fine with her chopping nuts with it. It’s gonna get used! Guess you might want them to appreciate the off the stones sharpness a little more, but...

Sounds like a good situation to use a microbevel.

Kawa

Senior Member

You are right. I know people hand wash it for 2 days and then put it back in the dishwasher... You are into knives or not..

At the end they are doing me a favor by letting me sharpen their knives. I wouldn't get better if I can't get my hands on enough knives from friends & family.

And they know I look at it this way.

My crying and making fun of the abuse comes with a grain of salt

(Responding to @ian )

At the end they are doing me a favor by letting me sharpen their knives. I wouldn't get better if I can't get my hands on enough knives from friends & family.

And they know I look at it this way.

My crying and making fun of the abuse comes with a grain of salt

(Responding to @ian )

Kawa

Senior Member

Sounds like a good situation to use a microbevel.

I think the microbevel needs a microbevel to survive that

FTFYSounds like a good situation to use a macrobevel.

augerpro

Senior Member

- Joined

- Jan 20, 2013

- Messages

- 320

- Reaction score

- 14

I think wire edges are the first stumbling block people run into when they finally learn how to get a super sharp edge. I know it was for me. Echoing others above, burr removal is the most important step to a long lasting edge. After a very long path of trying different techniques, the following is my current method and I'm finally very satisfied. I need only sharpen every six months or so in a home kitchen. I should mention what really pushed my method to what it is now is the scienceofsharp.com tests. Once you could actually see what was happening at the edge with different techniques, you could start to understand the mechanism and that takes the voodoo out of it - which required tons of experience to arrive at a good method.

1) edge-leading strokes on 1k Shapton GS stone

2) strop on 1k stone. *I've changed this a lot over the years too, I now only do about 3-4 strokes then switch sides, then drop to 1 stroke and flip back and forth. There is a high risk of over-doing stropping and actually creating a wire edge. The real goal is to weaken and remove the burrs, and I think flipping back and forth doing only one stroke helps with this.

3) strop on 1.0 micron diamond spray loaded kangaroo leather. Technique just like above.

4) edge-leading strokes on 4k Shapton GS

5) strop on 4k stone as above

6) strop on 0.5 micron diamond spray loaded kangaroo strop as above

Over-doing any of the steps above is a problem. Experiment with the stropping pressure for the loaded leather step. I typically use just a bit of pressure after stropping the 1k stone, but very little on the final strop. I no longer pull through cork after seeing the results at scienceofsharp. Yes it removes the burr well, but also just yanks chunks out of the edge. working against the work you've just done.

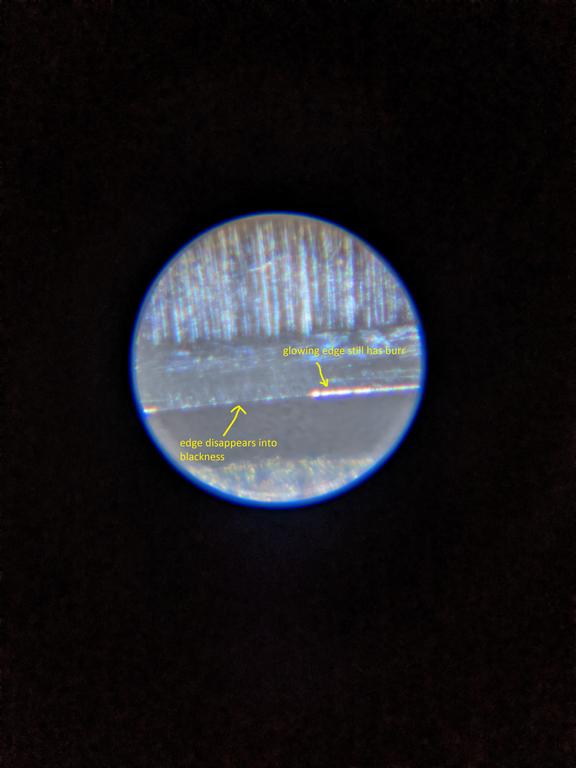

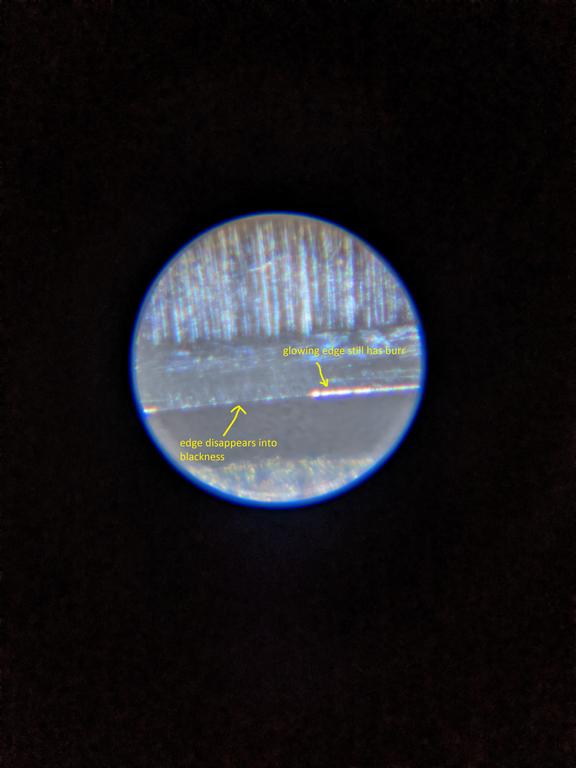

I've also always inspected the edge with one of those cheap little microscopes and I've now been able to correlate what I see with the long edge retention. It's important that you hold the microscope with the light on the bottom as shown below. What I've noticed is that when the edge just disappears into the blackness, the burr and any "frays" are gone and it will last a long time. If you see the edge lit up, the burr is still there and will fold and deform, shortening the service life. I should mention that years ago when I focused on stropping, I often overdid it and the knife wouldn't bite into vegies (I was also finishing at 8k Shapton GS too). In that case - I don't really remember - I probably had removed that lit up burr in the microscope but had over-smoothed or even rounded the edge. So the trick is to find the stropping technique that removes that lit up edge with the fewest strokes and least amount of pressure. The key is doing just enough to pull the little jaggies off the edge, and have a nice straight apex that you see in the scienceofsharp photos.

*the knife below is used, not freshly sharpened, but it illustrates what I look for at the edge

1) edge-leading strokes on 1k Shapton GS stone

2) strop on 1k stone. *I've changed this a lot over the years too, I now only do about 3-4 strokes then switch sides, then drop to 1 stroke and flip back and forth. There is a high risk of over-doing stropping and actually creating a wire edge. The real goal is to weaken and remove the burrs, and I think flipping back and forth doing only one stroke helps with this.

3) strop on 1.0 micron diamond spray loaded kangaroo leather. Technique just like above.

4) edge-leading strokes on 4k Shapton GS

5) strop on 4k stone as above

6) strop on 0.5 micron diamond spray loaded kangaroo strop as above

Over-doing any of the steps above is a problem. Experiment with the stropping pressure for the loaded leather step. I typically use just a bit of pressure after stropping the 1k stone, but very little on the final strop. I no longer pull through cork after seeing the results at scienceofsharp. Yes it removes the burr well, but also just yanks chunks out of the edge. working against the work you've just done.

I've also always inspected the edge with one of those cheap little microscopes and I've now been able to correlate what I see with the long edge retention. It's important that you hold the microscope with the light on the bottom as shown below. What I've noticed is that when the edge just disappears into the blackness, the burr and any "frays" are gone and it will last a long time. If you see the edge lit up, the burr is still there and will fold and deform, shortening the service life. I should mention that years ago when I focused on stropping, I often overdid it and the knife wouldn't bite into vegies (I was also finishing at 8k Shapton GS too). In that case - I don't really remember - I probably had removed that lit up burr in the microscope but had over-smoothed or even rounded the edge. So the trick is to find the stropping technique that removes that lit up edge with the fewest strokes and least amount of pressure. The key is doing just enough to pull the little jaggies off the edge, and have a nice straight apex that you see in the scienceofsharp photos.

*the knife below is used, not freshly sharpened, but it illustrates what I look for at the edge

I'm new to sharpening (about 20-25 sessions), and with a weekly sharpen - having an AO super steel core and a soft cutting board is all i need to retain edge. I've only ever had one Japanese knife and only for about 6 weeks so take my word with a grain of salt.how do I get that mythical edge retention that people are talking about?

I cook and prep with an apprentice (so I do the bulk of the work) for 90 people daily and this new blade shaves hair all week without a touch up on a single stone.

Avoid rock chopping, or at least heavy rock chopping. Don't use honing rod. Maybe whack it on a strop during a particularly heavy day.

End of the week - 10 mins on 1000 grit and 5 mins on a 3000. Then I have a laser for the beginning of the next week to last 5 more days. The edge lasts plenty.

Burr removal may be the culprit or not maintaining same angle during sharpening..?