So I had a new-to-me experience today.

Subject knife is a Hatsukokoro AS Bunka. Hatsukokoro Kurosagi 180mm AS Bunka

Just got it yesterday. The OOTB edge was okay but definitely up to standard and the last ~1/2" or so of the heel was actually pretty dull. It was a near zero grind and I just basically didn't pay a lot of attention and chalked it up to a lower-end knife grind.

I put it on my SG500 first and...

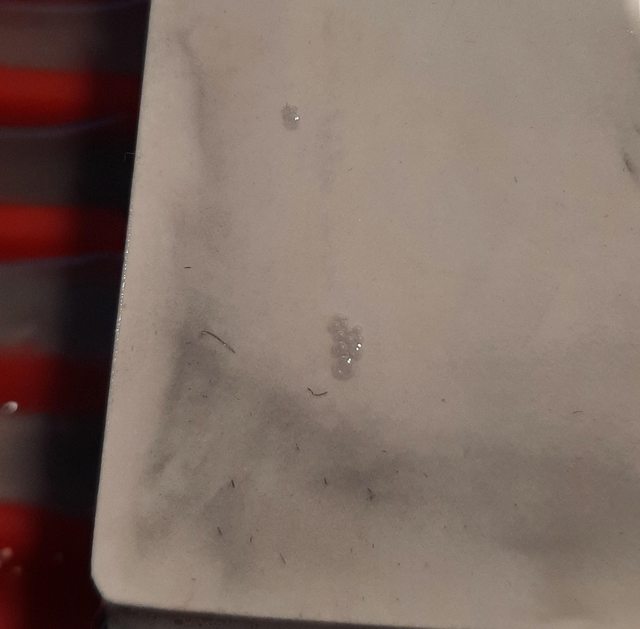

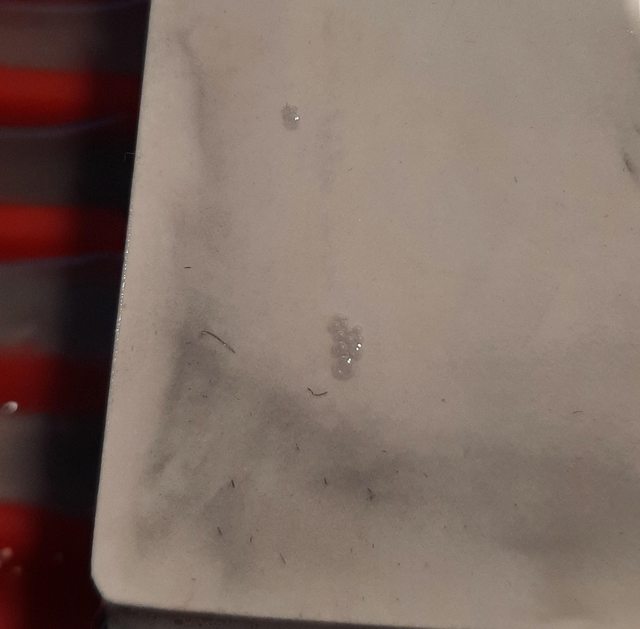

It burred up really quickly and obviously significantly.

I'm not sure I've ever encountered that kind of rapid and huge burr formation on even the softest knives I've sharpened. Happened on both sides to start. I kinda do a loose Peter Nowlan style of sharpening with decreasing pressure but when I realized the kind of burrs I was getting, I did a couple additional higher pressure passes on each side than I normally do. Then it seemed to clean up and started to "normalize". I did a LOT of light edge trailing, de-burring strokes and then stropped on suede with CrO, cardboard, and hell, even my flannel PJ pants! I pretty much never do that between stones but I want that nasty ass burr gone!

I went to my SG2k and everything felt normal and as expected. Again, more-than-normal de-burring strokes on the stone and then on some cardboard.

Decided to go to my SG4k and really just did feather light passes and de-burring.

When I was done it was singing through paper towel. I was a little hyper sensitive but I believe the steel didn't feel bad on the stones.

I know bad heat treat might be tossed out as a potential culprit and maybe it is, especially at this price point, but I feel like that's a too frequent go-to. And given that it felt like things sorted out, I'm inclined to think it was just a crappy original job and likely left some weak steel hanging on at the very edge.

I know I need to use it and see how it holds up but what do you guys think?

Subject knife is a Hatsukokoro AS Bunka. Hatsukokoro Kurosagi 180mm AS Bunka

Just got it yesterday. The OOTB edge was okay but definitely up to standard and the last ~1/2" or so of the heel was actually pretty dull. It was a near zero grind and I just basically didn't pay a lot of attention and chalked it up to a lower-end knife grind.

I put it on my SG500 first and...

It burred up really quickly and obviously significantly.

I'm not sure I've ever encountered that kind of rapid and huge burr formation on even the softest knives I've sharpened. Happened on both sides to start. I kinda do a loose Peter Nowlan style of sharpening with decreasing pressure but when I realized the kind of burrs I was getting, I did a couple additional higher pressure passes on each side than I normally do. Then it seemed to clean up and started to "normalize". I did a LOT of light edge trailing, de-burring strokes and then stropped on suede with CrO, cardboard, and hell, even my flannel PJ pants! I pretty much never do that between stones but I want that nasty ass burr gone!

I went to my SG2k and everything felt normal and as expected. Again, more-than-normal de-burring strokes on the stone and then on some cardboard.

Decided to go to my SG4k and really just did feather light passes and de-burring.

When I was done it was singing through paper towel. I was a little hyper sensitive but I believe the steel didn't feel bad on the stones.

I know bad heat treat might be tossed out as a potential culprit and maybe it is, especially at this price point, but I feel like that's a too frequent go-to. And given that it felt like things sorted out, I'm inclined to think it was just a crappy original job and likely left some weak steel hanging on at the very edge.

I know I need to use it and see how it holds up but what do you guys think?

Last edited: