Are the pins brass?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Martell Knife Blanks: WIP

- Thread starter Kippington

- Start date

Help Support Kitchen Knife Forums:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well the fit on the pins looks good from where I'm sitting.

milkbaby

Well-Known Doofus

That's looking good! Interested to see the complete finished knife.

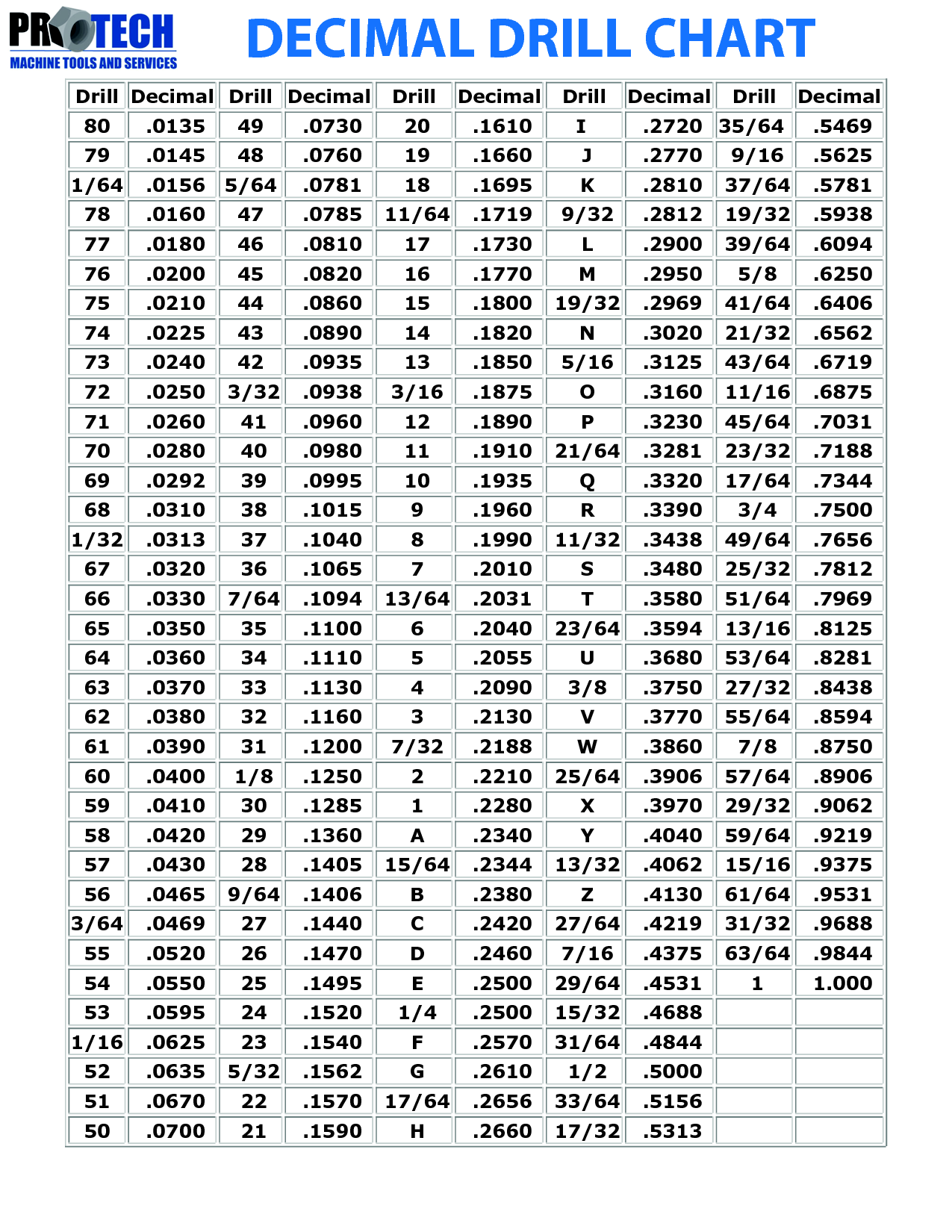

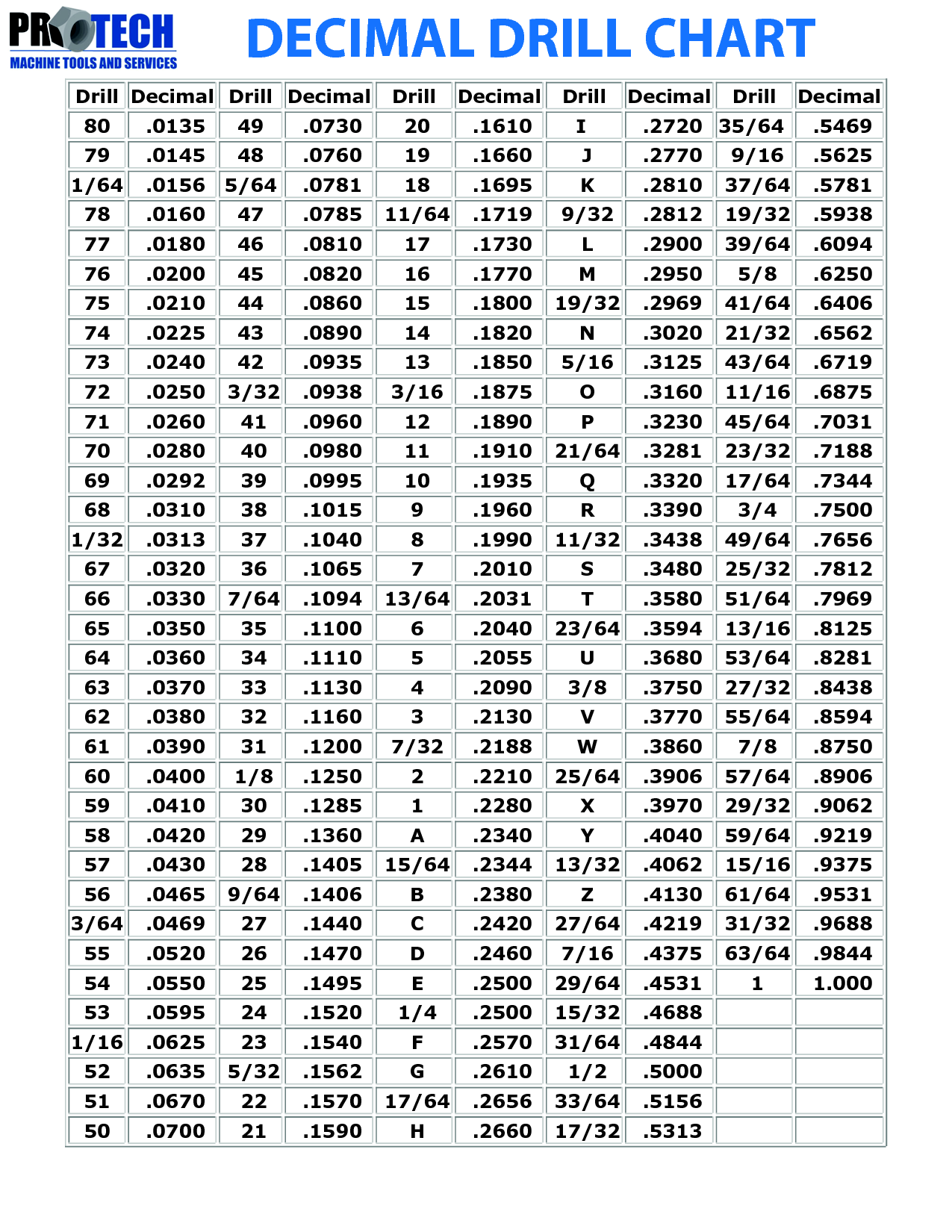

For drilling holes, I always size up one step from the actual pin diameter with a fractional drill bit. For example, drilling for a 1/8" (0.125") diameter pin I'll use a #30 drill bit which is 0.1285". This is less likely to crack the wood scales.

For drilling holes, I always size up one step from the actual pin diameter with a fractional drill bit. For example, drilling for a 1/8" (0.125") diameter pin I'll use a #30 drill bit which is 0.1285". This is less likely to crack the wood scales.

That's good advice - looks like I tool the right approach. Here's some pics of the knife nearly finished. The handle still has a few coats to go - 2 coats tung oil / orange oil + 2 coats pure tung oil + 2 coats tung oil / beeswax (with 24 hours and a steel wool in between). I also need to put an edge on. There are plenty of visible flaws, but I'm very happy with how it came out. A few gouges in the handle that I didn't chase out, the forge scale is still visible on the tang in some places, I marked the very front of the blade near the handle when sanding etc... but this is my second ever knife and first western handle so I'm super happy. We even did some fancy stuff like a subtle distal taper, tapered tang, and rounded spine.

As mentioned, this would have been beyond impossible without the help of Kippington. Kipp has incredible knowledge and skill, is super generous, and is building up the gear for a mean workshop. It sounds like he's pretty much got a school of KKFrs over every weekend. Thanks a bunch. And sorry for the terrible pics - these are taken on my circa 2008 Nokia.

As mentioned, this would have been beyond impossible without the help of Kippington. Kipp has incredible knowledge and skill, is super generous, and is building up the gear for a mean workshop. It sounds like he's pretty much got a school of KKFrs over every weekend. Thanks a bunch. And sorry for the terrible pics - these are taken on my circa 2008 Nokia.

Oh man I didn't realize that it was a suji you made, you get extra points for that!

I was wondering, did you guys anneal the tang or work with it hard?

I was wondering, did you guys anneal the tang or work with it hard?

milkbaby

Well-Known Doofus

Nice job! I want to say that knife looks awesome but to be honest, your phone camera really sucks. :running: :biggrin:

But seriously, great job on the knife but it deserves better pics. Hope you use it a bunch and enjoy it! :doublethumbsup:

But seriously, great job on the knife but it deserves better pics. Hope you use it a bunch and enjoy it! :doublethumbsup:

Nice job! I want to say that knife looks awesome but to be honest, your phone camera really sucks. :running: :biggrin

I know - it's the worst. Here's one that at least had the benefit of daylight. I'll see if I can get some better pics eventually. It would be good to show the grind etc...

Been a while twixt drinks, so to speak. Feels as though I'm reviving a dormant thread. The grinding was completed some time back - with considerable assistance from @Kippington. Thanks so much!

Bought some AZ Desert Ironwood scales a while ago then finally decided I wasn't up to the task so I deferred to the wonderful workmanship of Cody Paul (aka @thegingerninja.abq on IG). Just returned from the US with the handled nakiri and I'm delighted with the result. Just a little bit more polishing and sharpening and it's ready for home duties.

Bought some AZ Desert Ironwood scales a while ago then finally decided I wasn't up to the task so I deferred to the wonderful workmanship of Cody Paul (aka @thegingerninja.abq on IG). Just returned from the US with the handled nakiri and I'm delighted with the result. Just a little bit more polishing and sharpening and it's ready for home duties.

Last edited:

Marek, I was right away thinking, "wow, he's got some handle skillz".....LOL

Nice work by you, Kip, & Cody. I hope you enjoy using it.

Nice work by you, Kip, & Cody. I hope you enjoy using it.