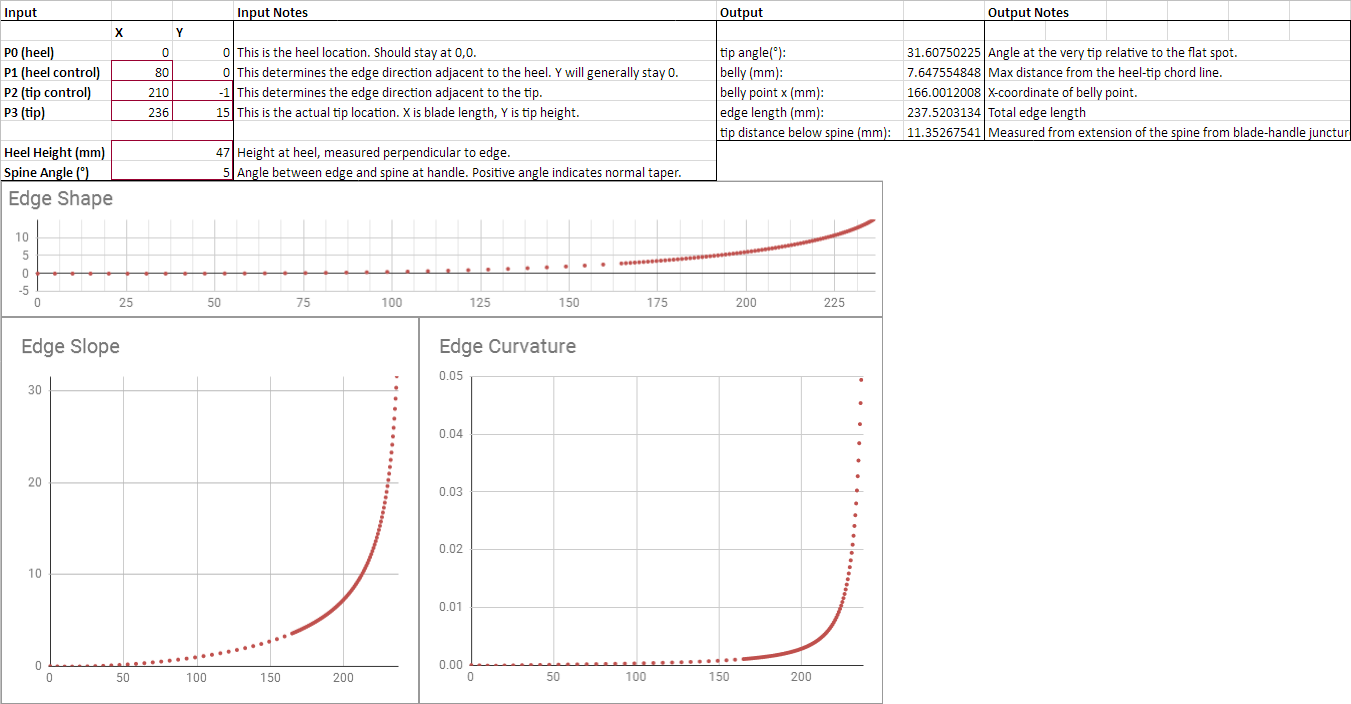

I'm glad you liked the spreadsheet. I put it together after I came across this thread. If you check the column labeled "R", that's the equivalent radius of curvature at each point.

My hope would be to (eventually) create a simple enough interface that it's approachable to anyone with an interest, and make the math(s) part somewhat optional.

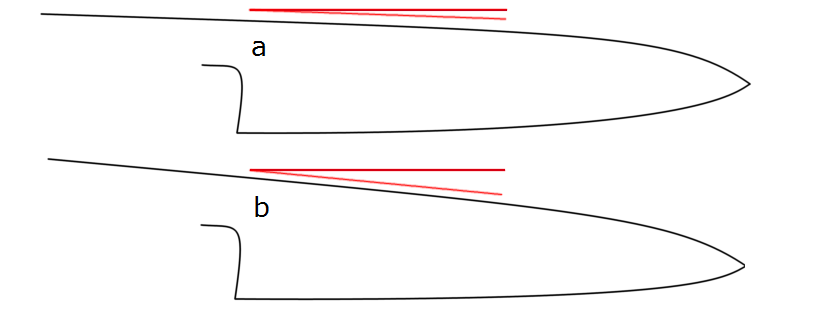

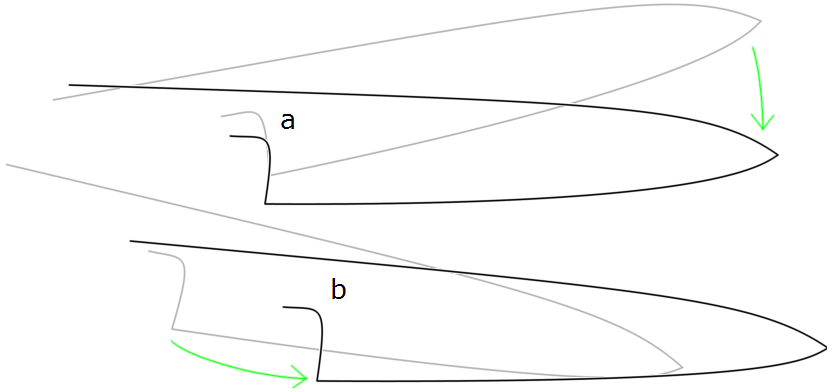

Finding the control point locations doesn't have to be too difficult, as long as you're comfortable making the curve match the edge. There are two fairly simple ways to get their locations.

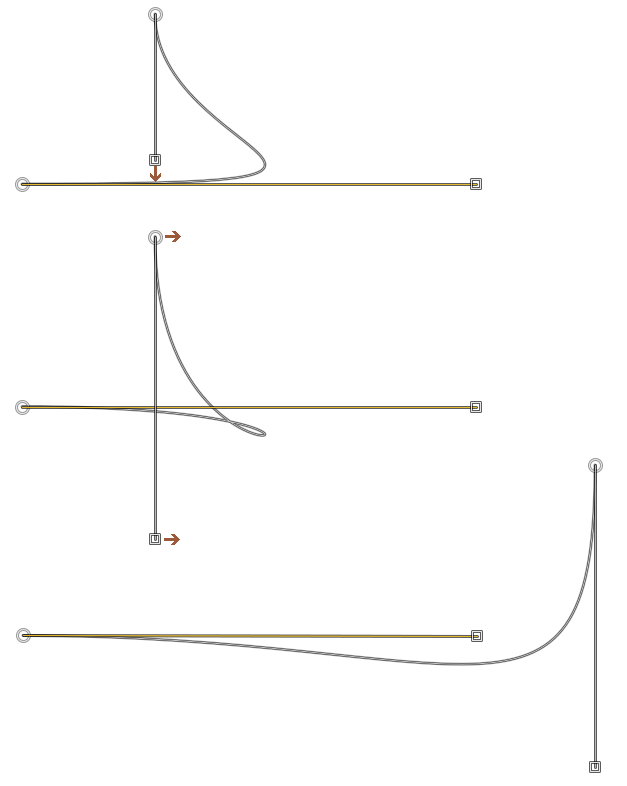

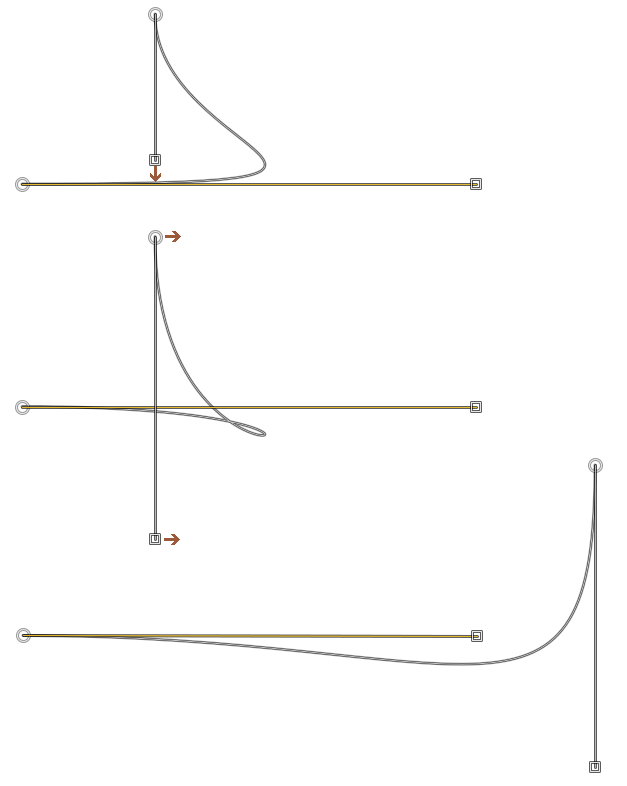

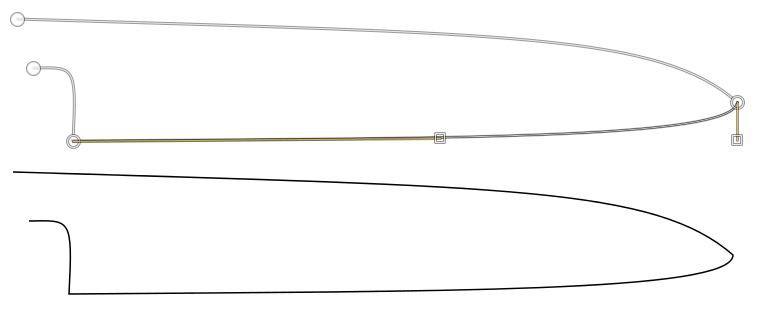

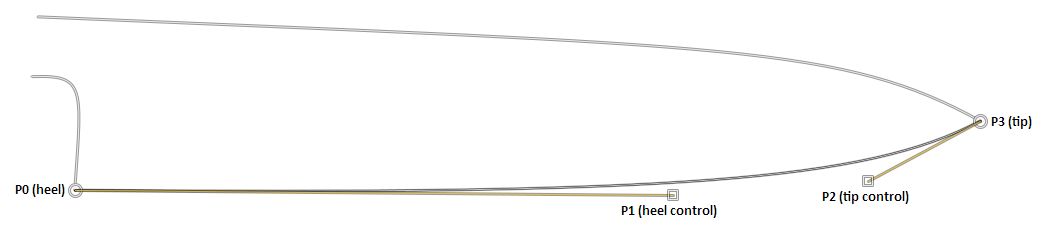

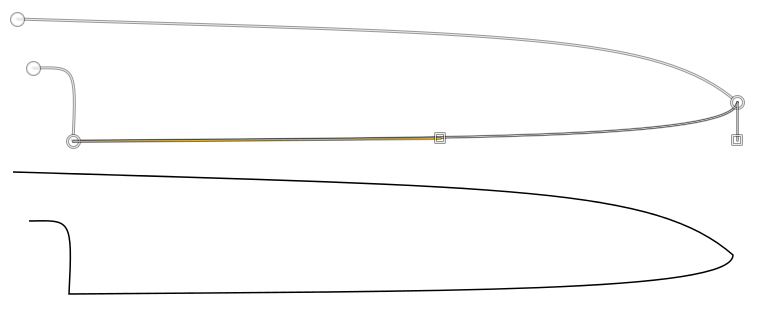

The first is to create your curve in 2D CAD - Draftsight is a freeoption from Dassault. You could use NanoCAD or Creo Sketch, or even AutoCAD if you've got it. You'll insert the image, put the heel at (0,0), draw the curve, then scale to get the right length. Then, you can select the spline and look at the coordinates of each control point:

In this example, we're looking at the 3rd control point (P2). You can select the other control points to get their coordinates.

The other way to do it is to create the curve in a vector graphics editor, like Inkscape or Illustrator. You'll then export as SVG, and pop that open in Notepad (or your text editor of choice). Look for a line like this:

Code:

<path class="st0" d="M0,0c55.2,0,223,1.92,240-19.2"/>

Depending on the application, that could alternately look like this:

Code:

<path class="st0" d="M0,0 c55.2,0 223.2,1.92 240,-19.2"/>

In the above example, you can parse the following points:

p0: (0,0)

p1: (55.2,0)

p2: (223,1.92)

p3: (240,-19.2)

Note that because SVG is oriented for web use, its Y-axis is inverted, so you'll want to negate the Y-values.

While you're in notepad, you can manually change those coordinates as desired and save - and it'll still open.

One real upside to the SVG approach is that it's in relative coordinates - so the location of p0 (the heel) doesn't matter as long as the flat spot is horizontal. That means that for a database, a user could simply upload an SVG with their trace of the edge, and everything else is handled simply in the backend. I will say that rotating things horizontal is much easier in CAD.