You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Restoring a Kasumi Finish?

- Thread starter mikedtran

- Start date

Help Support Kitchen Knife Forums:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

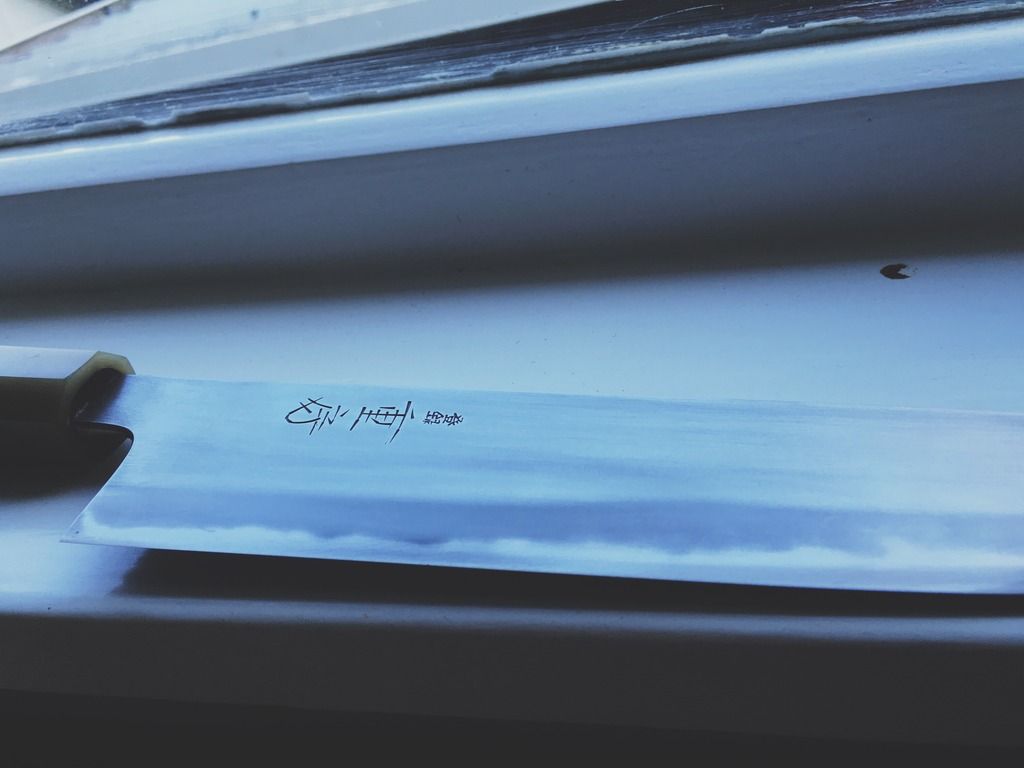

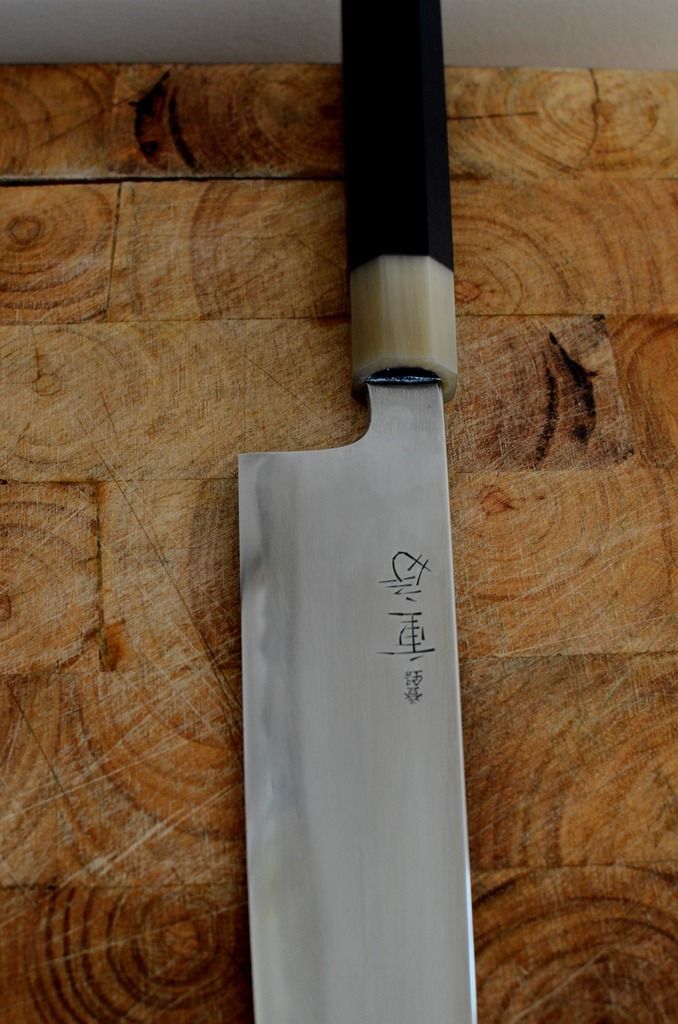

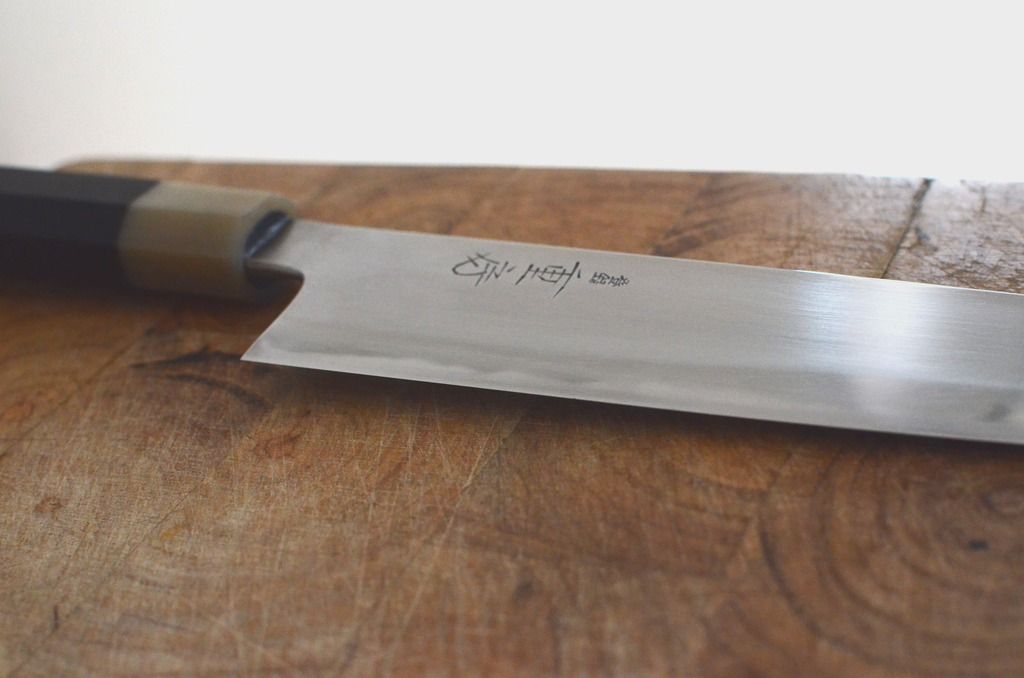

Just thought I'd pop this on as a nod to this thread as just about everything I did to get the finish to where it is is gleaned from here. Not perfect, but not hopeless either.

Naniwa 220

Imanishi 400

Chosera 1K

Chosera 3K

Aoto

Takenoko 8K

Maruoyama shiro suita

Oohira renge suita

Medium and fine scourer 200 thru 1200 wet&dry

Uchigumori fingerstone with 20k aluminium oxide powder

Cotton balls with uchi and Shinden suita slurry

Naniwa 220

Imanishi 400

Chosera 1K

Chosera 3K

Aoto

Takenoko 8K

Maruoyama shiro suita

Oohira renge suita

Medium and fine scourer 200 thru 1200 wet&dry

Uchigumori fingerstone with 20k aluminium oxide powder

Cotton balls with uchi and Shinden suita slurry

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

mikedtran

Banned

- Joined

- Aug 26, 2015

- Messages

- 1,395

- Reaction score

- 21

Just thought I'd pop this on as a nod to this thread as just about everything I did to get the finish to where it is is gleaned from here. Not perfect, but not hopeless either.

Naniwa 220

Imanishi 400

Chosera 1K

Chosera 3K

Aoto

Takenoko 8K

Maruoyama shiro suita

Oohira renge suita

Medium and fine scourer 200 thru 1200 wet&dry

Uchigumori fingerstone with 20k aluminium oxide powder

Cotton balls with uchi and Shinden suita slurry

Looks great!

Where did you source 20k aluminium oxide powder from?

Cheers,

Michael

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

Looks good to me. Hard to see things exactly in the photos, but it has to be a finer finish than the original, no?

Yes.... And no. There's one or two places where bad technique and figuring it out while I'm doing it lets the final finish down. My lines aren't as perfectly horizontal from heel to tip as OOTB. Also I'd like to better blend my thinning line with cladding which is visible in both photos. Tip is a little bit all over the show too. A luta continua.

My lines aren't as perfectly horizontal from heel to tip as OOTB. Also I'd like to better blend my thinning line with cladding which is visible in both photos. Tip is a little bit all over the show too. A luta continua.

Oh yeah, that line aspect is the hardest - and they use some sort of contraption for it in the workshop that we'll never have, of course. As for the thinning 'shadow' (different texture, looks darker towards the edge in the photos) I know what you mean. Actually, I think they can look good this way too, but if you want to kill it you'll just have to polish it more toward the edge and wear away your efforts with your nice jnat finishers that you thought would endure. Use the sandpaper, fingerstones, etc, and polishing near the edge, and just use your finisher on the hagane and a bit above, like when the knife comes new.

DDPslice

Senior Member

- Joined

- Jun 21, 2014

- Messages

- 335

- Reaction score

- 2

looking good, but unless your redefining or changing/lengthening your bevel each time you sharpen you don't have to go lower then 1000 (or you're taking out some serious chips), and when polishing up just stick to polishing side of the spectrum (>4000) unless you have scratches that you need to go deeper for. I'd stick the 20k powder with a cotton pad/sponge/silk after the uchi instead of with because the uchi will darken the ji and the 20k will smooth it out and lighten it just a little. And use the uchi with some baking soda(makes it lighter) or its own slurry (makes it darker) and or both.

for me what I worry about is what works for me. my tip is really thin and my heel is really thick and my bevel line is nowhere near strait and I've learned to use that to my advantage rather then waste effort making aesthetics my priority.

Some of the most frustrating things for me is, even though your technique may be perfect the stone isn't too friendly with the knife and no matter then skill or effort you can get close but pulling the beauty of the metal depends of finding the stone that works with the knife, so I mainly stick mainly to getting that screaming sharp edge and like butter slice.

Nice pics, glad to see you(r) progress.

for me what I worry about is what works for me. my tip is really thin and my heel is really thick and my bevel line is nowhere near strait and I've learned to use that to my advantage rather then waste effort making aesthetics my priority.

Some of the most frustrating things for me is, even though your technique may be perfect the stone isn't too friendly with the knife and no matter then skill or effort you can get close but pulling the beauty of the metal depends of finding the stone that works with the knife, so I mainly stick mainly to getting that screaming sharp edge and like butter slice.

Nice pics, glad to see you(r) progress.

Last edited:

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

looking good, but unless your redefining or changing/lengthening your bevel each time you sharpen you don't have to go lower then 1000 (or you're taking out some serious chips), and when polishing up just stick to polishing side of the spectrum (>4000) unless you have scratches that you need to go deeper for. I'd stick the 20k powder with a cotton pad/sponge/silk after the uchi instead of with because the uchi will darken the ji and the 20k will smooth it out and lighten it just a little. And use the uchi with some baking soda(makes it lighter) or its own slurry (makes it darker) and or both.

for me what I worry about is what works for me. my tip is really thin and my heel is really thick and my bevel line is nowhere near strait and I've learned to use that to my advantage rather then waste effort making aesthetics my priority.

Some of the most frustrating things for me is, even though your technique may be perfect the stone isn't too friendly with the knife and no matter then skill or effort you can get close but pulling the beauty of the metal depends of finding the stone that works with the knife, so I mainly stick mainly to getting that screaming sharp edge and like butter slice.

Nice pics, glad to see you(r) progress.

This was a great post, thank you. I was lengthening the bevel a bit to get past some hesitation it had in denser ingredients and when I was happy with the geometry I was terrified by the finish, thinking I'd thunderf*cked a perfectly good Shig. Hence a trip to the hardware for scrubbies and wet 'n dry. I think I will keep the uchi and WA separate as you mention and try applying the WA with a soft substrate. Keen to try the baking soda.

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

Where would one source 20k Aluminum Oxide powder? I checked google / amazon / ebay and really must be failing?

Any thoughts on if there is a better powder for polishing than 20k Aluminum Oxide powder?

Got mine from a guy who did some work at a metal fabricators. Search "WA powder 2000" seems to return a few hits in the states

DDPslice

Senior Member

- Joined

- Jun 21, 2014

- Messages

- 335

- Reaction score

- 2

This was a great post, thank you. I was lengthening the bevel a bit to get past some hesitation it had in denser ingredients and when I was happy with the geometry I was terrified by the finish, thinking I'd thunderf*cked a perfectly good Shig. Hence a trip to the hardware for scrubbies and wet 'n dry. I think I will keep the uchi and WA separate as you mention and try applying the WA with a soft substrate. Keen to try the baking soda.

No matter how deep you go a good polishing will always bring out craftsmanship of the shig. Japanese knives and swords are meant to last a lifetime of sharpening (or several with good care and attention) so don't be afraid, but also don't go crazy.

Im about to pick up my second set from amazon

http://www.amazon.com/dp/B003ELH7AI/?tag=skimlinks_replacement-20

Last edited by a moderator:

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

Yup, getting mine from a local pen making place. And I agree, I think I'm a custodian of a Shig more than an owner

Those pads are great, but they start at 1200 grit what may be a little too much, or so I wonder.

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

Yup but scale 2.5 to get it back to sandpaper grits

Coloured Micro Mesh polishing pad set.

Set includes 9 grits: 1500, 1800, 2400, 3200, 3600, 4000, 6000, 8000 and 12000.

Where 1500 is slightly coarser than normal 600 grit paper.

Thanks for the info!

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

YG420

Senior Member

- Joined

- Jul 2, 2015

- Messages

- 1,083

- Reaction score

- 606

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

I erm... Went through the entire rainbow. Then paste of baking soda with uchi fingerstone

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

Some proprietary Swedish steel of undisclosed composition

Badger, as is usual you've got that different kind of texture/darkness on the wider bevel. You might try using the same slurry from your final stone (and even also the earlier stones) to polish beyond the bevel. Might get a more uniform look.

On the other hand, the finish doesn't need to be uniform. Matter of taste.

On the other hand, the finish doesn't need to be uniform. Matter of taste.

Badgertooth

Senior Member

- Joined

- Nov 5, 2015

- Messages

- 2,664

- Reaction score

- 655

Badger, as is usual you've got that different kind of texture/darkness on the wider bevel. You might try using the same slurry from your final stone (and even also the earlier stones) to polish beyond the bevel. Might get a more uniform look.

On the other hand, the finish doesn't need to be uniform. Matter of taste.

Yeah, I think it's because with the initial sharpening a few weeks ago I used a pretty tight progression for scratch deletion and ended up with a very polished bevel without the foresight to keep a bit of slurry from each stone. So I'll try and use the same progression on another wide-bevel and keep some slurry.

As an aside, I saw on the JNS that WA powder is best used with camellia oil and I tried it... Vastly different and more refined finish than using it with water. Which poses an interesting question: what would happen if you used stone slurry with camellia oil?

mikedtran

Banned

- Joined

- Aug 26, 2015

- Messages

- 1,395

- Reaction score

- 21

Yeah, I think it's because with the initial sharpening a few weeks ago I used a pretty tight progression for scratch deletion and ended up with a very polished bevel without the foresight to keep a bit of slurry from each stone. So I'll try and use the same progression on another wide-bevel and keep some slurry.

As an aside, I saw on the JNS that WA powder is best used with camellia oil and I tried it... Vastly different and more refined finish than using it with water. Which poses an interesting question: what would happen if you used stone slurry with camellia oil?

On the camellia oil note. I do all my sanding with camellia oil, no water. I prefer the feel much more.

- Joined

- Feb 28, 2011

- Messages

- 6,006

- Reaction score

- 213

On the camellia oil note. I do all my sanding with camellia oil, no water. I prefer the feel much more.

Mobil 1 works just as well and is quite a bit less expensive.

Amsoil?

fryer oil, foodsafe

DDPslice

Senior Member

- Joined

- Jun 21, 2014

- Messages

- 335

- Reaction score

- 2

I like to use slurry, with jnats (any stone) the slurry partials are meant to break down finer and finer. Also when I'm on my finishing polish 8k+ I will go over the entire knife, it just leaves it silky smooth. And I test the smoothness as a wipe it with a cloth in my hands. When it slips through I know I'm done.

also please only use food safe items unless you are a chemist.

also please only use food safe items unless you are a chemist.

As an aside, I saw on the JNS that WA powder is best used with camellia oil and I tried it... Vastly different and more refined finish than using it with water. Which poses an interesting question: what would happen if you used stone slurry with camellia oil?

I haven't tried WA with camellia, tho maybe with mineral oil. I've tried nat stone powder (uchigumori) with oil and preferred my usual water method, I think as it was easier to see and keep track of progress.

Problem with using oil with your stone slurry, if you don't have powder, then how will avoid oiling up your stones? Usually you'll generate some slurry with some means, and you won't use oil for that, and then you'll apply the slurry to the knife. To me the oil method only works if you have powder, natural or otherwise.