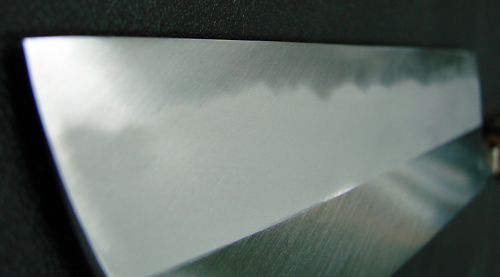

K-Fed, thats quite sexy looking effect and the knife itself is an appealing one

Tristan, the wavy line is there all the time, if you have a blade with two metals.

Well, not every knife actualy have the joint wavy, somecheapo yanagibas would have the connection completely flat.

To bring it out, You dont really need natural stones. Just regular 1K stone is enough to make it visible, then you need more time and patience and stones to get the better effect.

It will be visible after 1k, but it wont be crisp

If I would use natural stones, and have the secondary/primary connecting just where the metals come together - so the hamaguri I currently have, I would first start of working on the mud from the iron, then, when I would be satisfied and couldnt polish it more on that stone, I would move to sharpening the steel. The same action with all the rest of your stones. Pressure changes also as you work at a stone, not only when you change stone. What I mean when you built up the mud and you have nice paste there, you just slide the blade on it. It doesnt really feel like you touch the stones surface.

I used my middle finger and thumb to hold sanding paper on place and the cork itself. I used the index finger as guide sliding on the spine. The middle finger is also working as a weight on the cork. The cork was quite dry, i first trimmed it a bit so its surface is flat.