Beautiful cleaver! Is it bad form to ask for specs and price on a custom?MSC Custom Magnacut Cleaver Review

210x90mm, ~288g

Short review of this awesome cleaver Matt Sicard @MSicardCutlery made for me late last year. I've had a chance to use it now for a few weeks, so here are some of my thoughts.

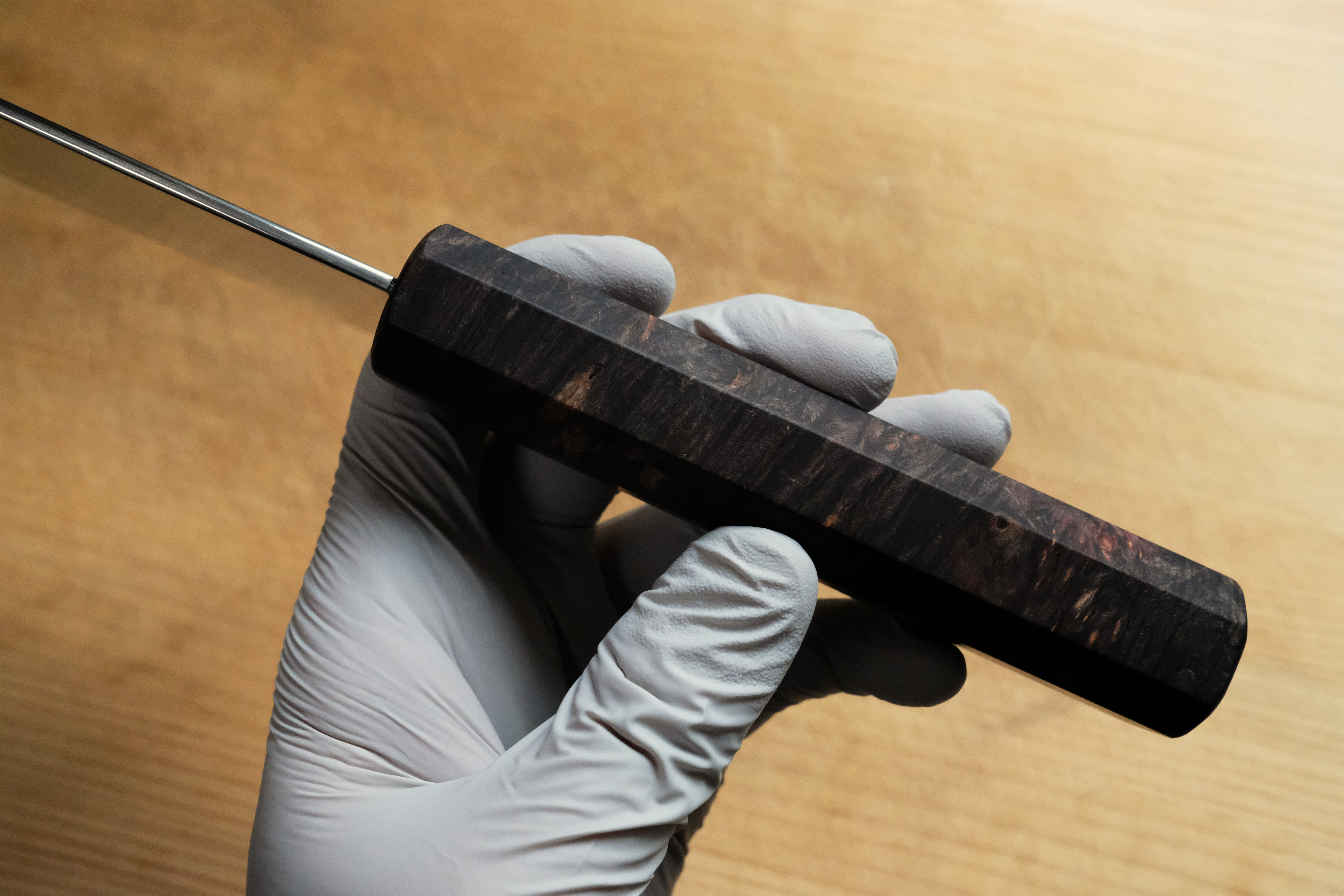

Starting off with the specs. I provided Matt with my preferred parameters such as size, profile, approximate weight, and also asked for his laser grind. He nailed it to the mm on length, width, and got the flat yet continuous profile spot on. He also added some distal taper along the spine, which was nicely done. The grind is also very clean, more on this later. The handle is red oak, which I requested to be unfinished so that I could dial in and attach myself. There was actually an issue with the wood handle that came up as I was installing, and Matt went ahead and shipped me out a brand new one right away after I mentioned it to him. Super customer service!

This thing has been so much fun to use. It's a little bit more robust than the benchmark CCK 1303, with a thinner BTE grind, and an amazing steel. The high convex laser grind is well executed, maintaining its thinness way high up the blade (it's around 1.1mm @20mm behind the edge). Falls through the densest of veggies with ease. The edge retention on the Magnacut is better than anything I've used previously. It's also capable of taking just as fine of an edge as my typical carbon steels. On the stones, it's more wear resistant than simple carbon steels, but my stones are able to sharpen it just fine (shapton pros and BBW). The corrosion resistance is also nice to have for those time when I know I won't have time to keep the blade clean for extended periods of time. One of the days I was testing it, I was managing so many things at once. I left it on the kitchen counter on top of a pile of diced tomatoes for an hour before I had a chance to get back to it. It feels great to have a high end stainless option in my arsenal for situations like this.

Communicating with Matt to make this commission a reality was probably one of the easiest interactions I've had with a custom maker. It took only a few weeks from the time we finalized the design until the knife was in the mail. I think it took him less time to complete the knife than the postal service took to deliver it during the holidays. Matt's offerings are such good value for what you get. I highly recommend his work to anyone looking to get a custom laser.

View attachment 221175View attachment 221174

Thanks for the great review!