WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 5

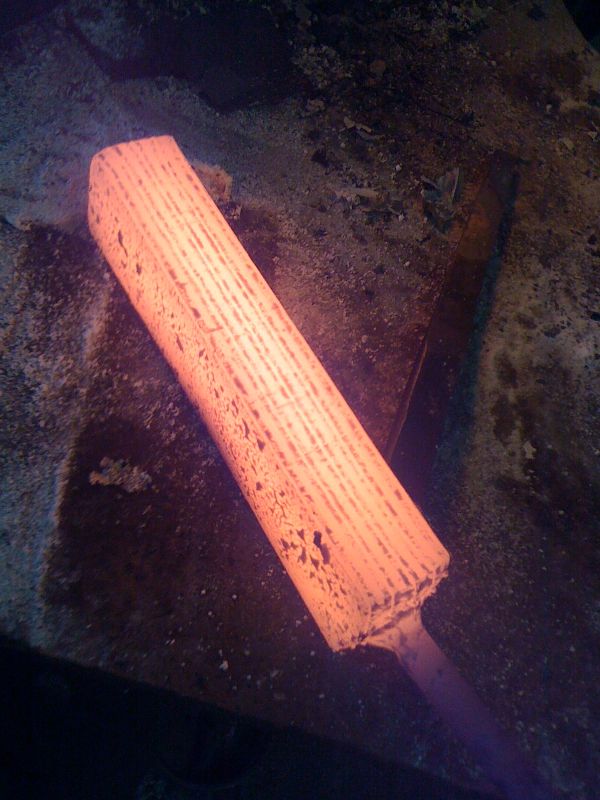

Here we have a 9 bar composite prepped for welding. Alternating tight twist of pure nickel/01 and 15n20. The Top bar is a soft twist in 1080/15n20 and pure nickel. So the spine will be softer after HT and temper. The edge is a solid layer of 01 steel.

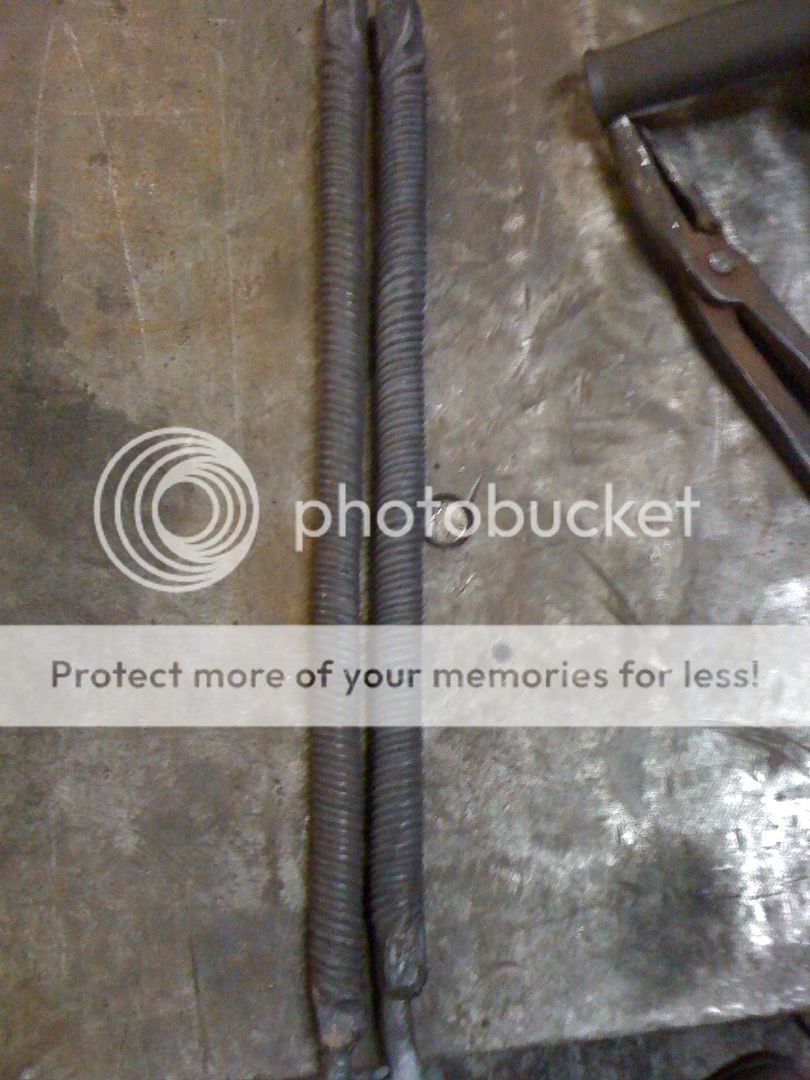

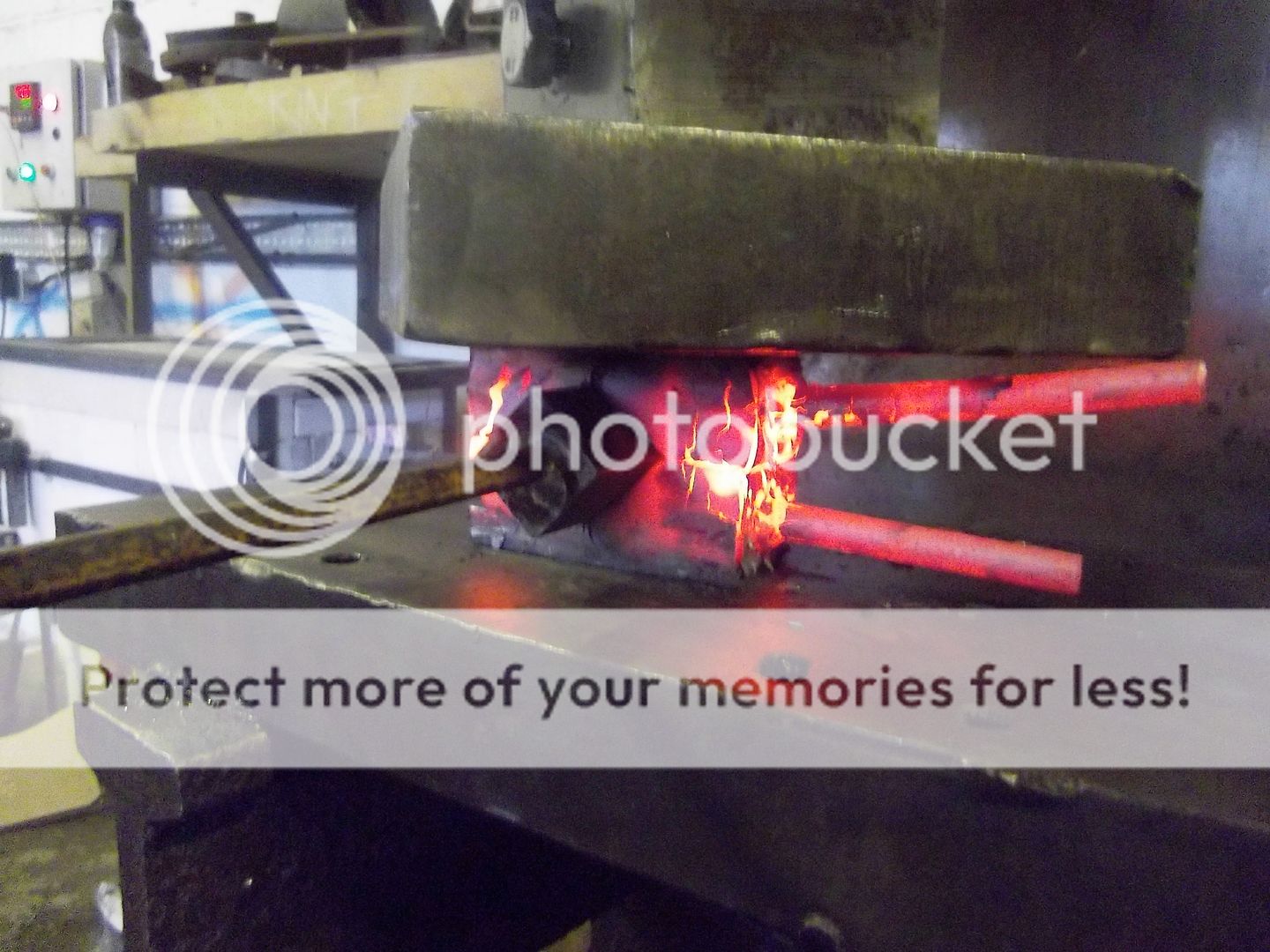

The stack after welding grinding clean and etching. This shows the twist pattern in their compressed state, only the outside of the twists are currently visible.

This shows the details of the different metals. The pure nickel is brightest, then 15n20, the 01 as etched appears black.

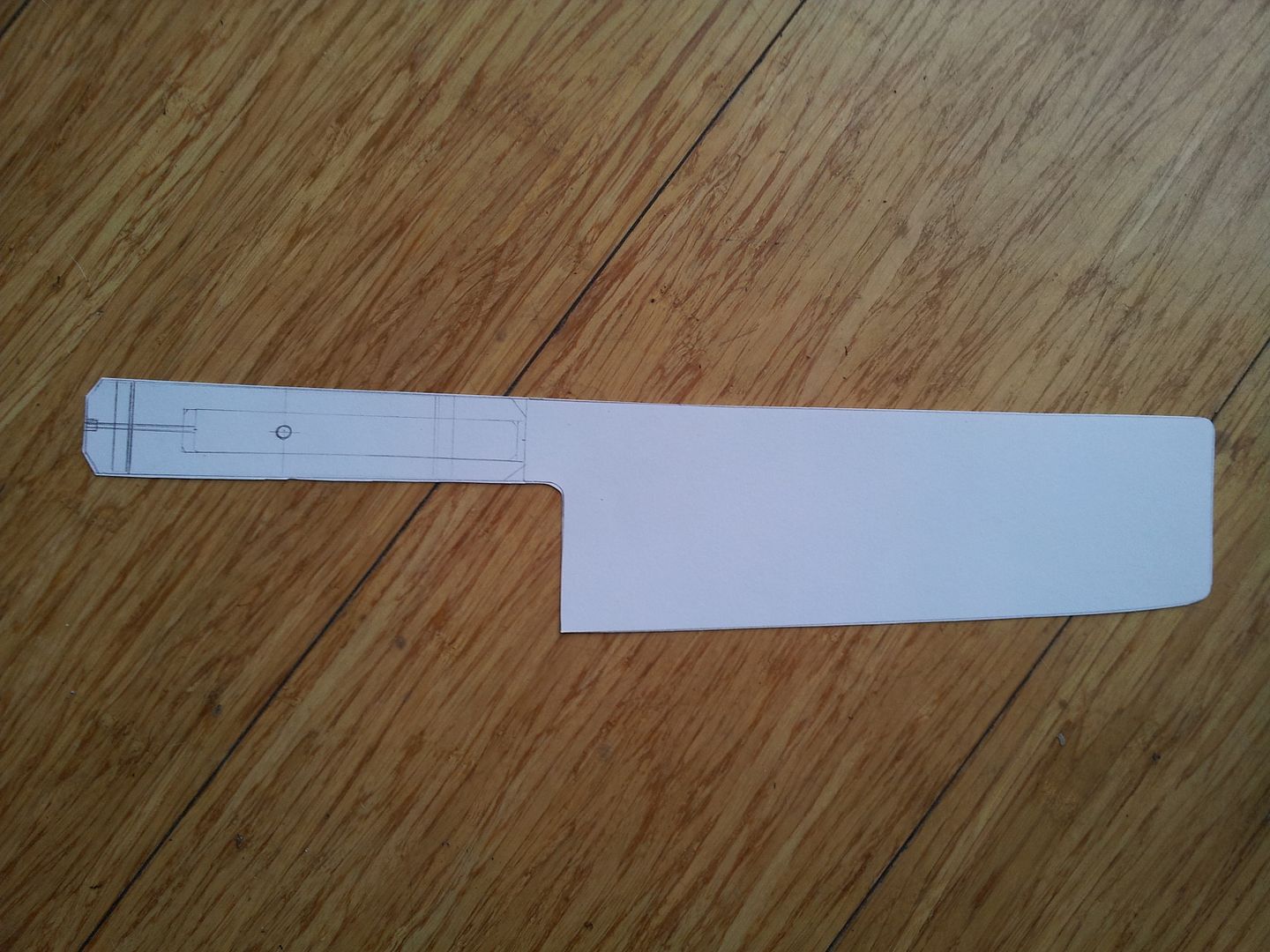

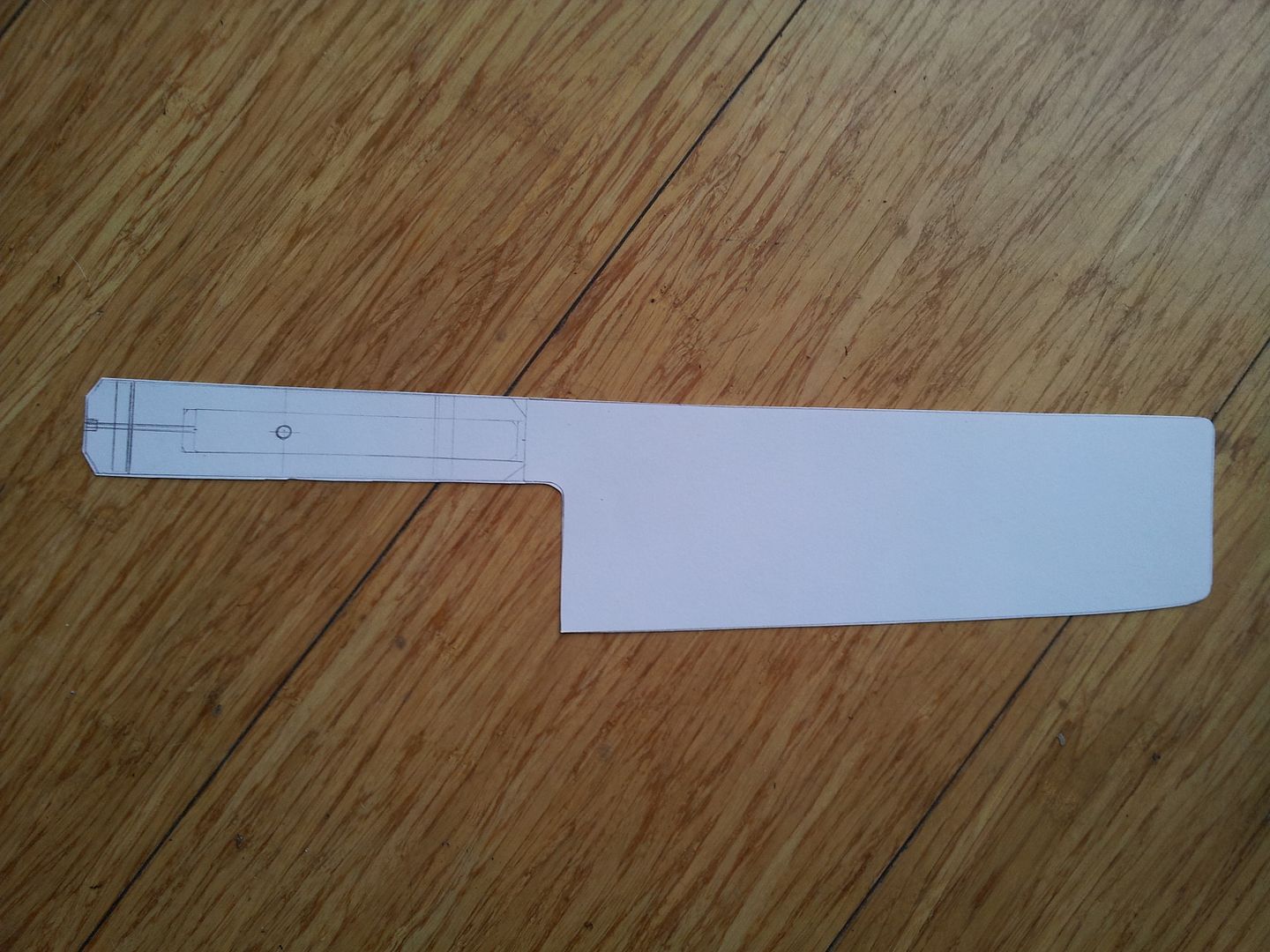

Plan for the Cleaver. The plan has evolved as I have worked as it has been that type of piece. it will be a tall heavier build Nakiri, Thick on the spine but full distal taper and hollow faces, a flat bevel each side. Extreme geometry. The handle will be damascus jade and nickel silver with high grade Koa wood.

The billet now forged close to final taper and ground clean. The Taper is 4mm over the choil to 1mm at the tip. Bevels are not ground at this stage. Blade is now ready for heat treatment.

Pattern details, the pattern now forged out is decompressed. The stars towards the core of the twists are already visible and will become more pronounced as the geometry is ground.

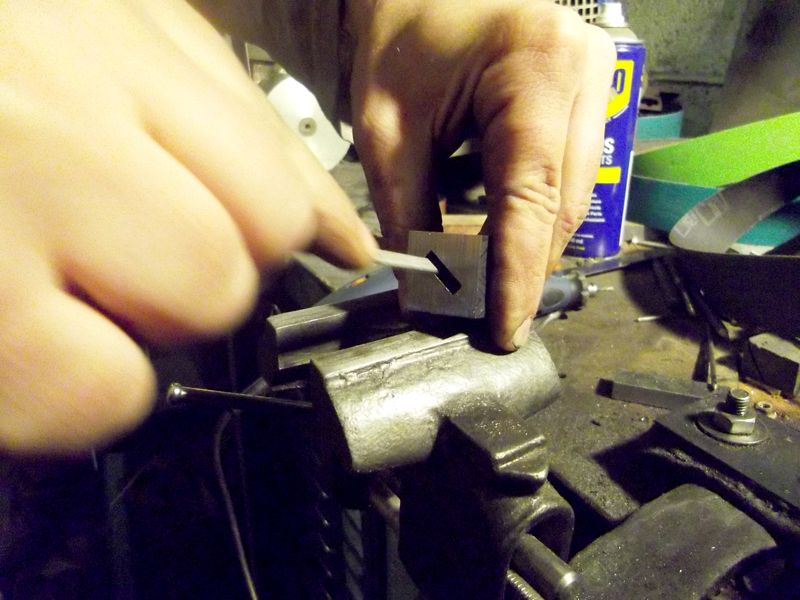

The blade has been heat treated. The edge tested to 65-66hrc as quenched. This was tempered back to 61 hrc, just a perfect balance for 01. Bevels are now being ground and hollow grinding on the faces of the blade from the spine to behind the bevels.

Grinding is nearly finished, i have put an edge on the blade to test it on food at home. Now I will make final adjustments to the geometry and move to hand finishing.

The stack after welding grinding clean and etching. This shows the twist pattern in their compressed state, only the outside of the twists are currently visible.

This shows the details of the different metals. The pure nickel is brightest, then 15n20, the 01 as etched appears black.

Plan for the Cleaver. The plan has evolved as I have worked as it has been that type of piece. it will be a tall heavier build Nakiri, Thick on the spine but full distal taper and hollow faces, a flat bevel each side. Extreme geometry. The handle will be damascus jade and nickel silver with high grade Koa wood.

The billet now forged close to final taper and ground clean. The Taper is 4mm over the choil to 1mm at the tip. Bevels are not ground at this stage. Blade is now ready for heat treatment.

Pattern details, the pattern now forged out is decompressed. The stars towards the core of the twists are already visible and will become more pronounced as the geometry is ground.

The blade has been heat treated. The edge tested to 65-66hrc as quenched. This was tempered back to 61 hrc, just a perfect balance for 01. Bevels are now being ground and hollow grinding on the faces of the blade from the spine to behind the bevels.

Grinding is nearly finished, i have put an edge on the blade to test it on food at home. Now I will make final adjustments to the geometry and move to hand finishing.