Inspired by threads about SiC powder flattening, I thought I'd post up how I flatten and dress a stone. Wrote this up for the razor forum, figured I'd cross post here as long as it's written up. Useful for all kinds of stones, not just Arks.

Today I'm dressing a hard black Ark with unknown branding, a $20 used tool store find that was finished very rough, maybe 36 grit on all surfaces when purchased. I was hoping I might luck into something like Keith Johnson's favorite, opaque black ark. This one is totally opaque, with some lighter figuring/veins much like the one he's fond of. I doubt this one is equal, but the search is always the fun part.

Anyway, here goes, and you can see how things change slowly along the way.

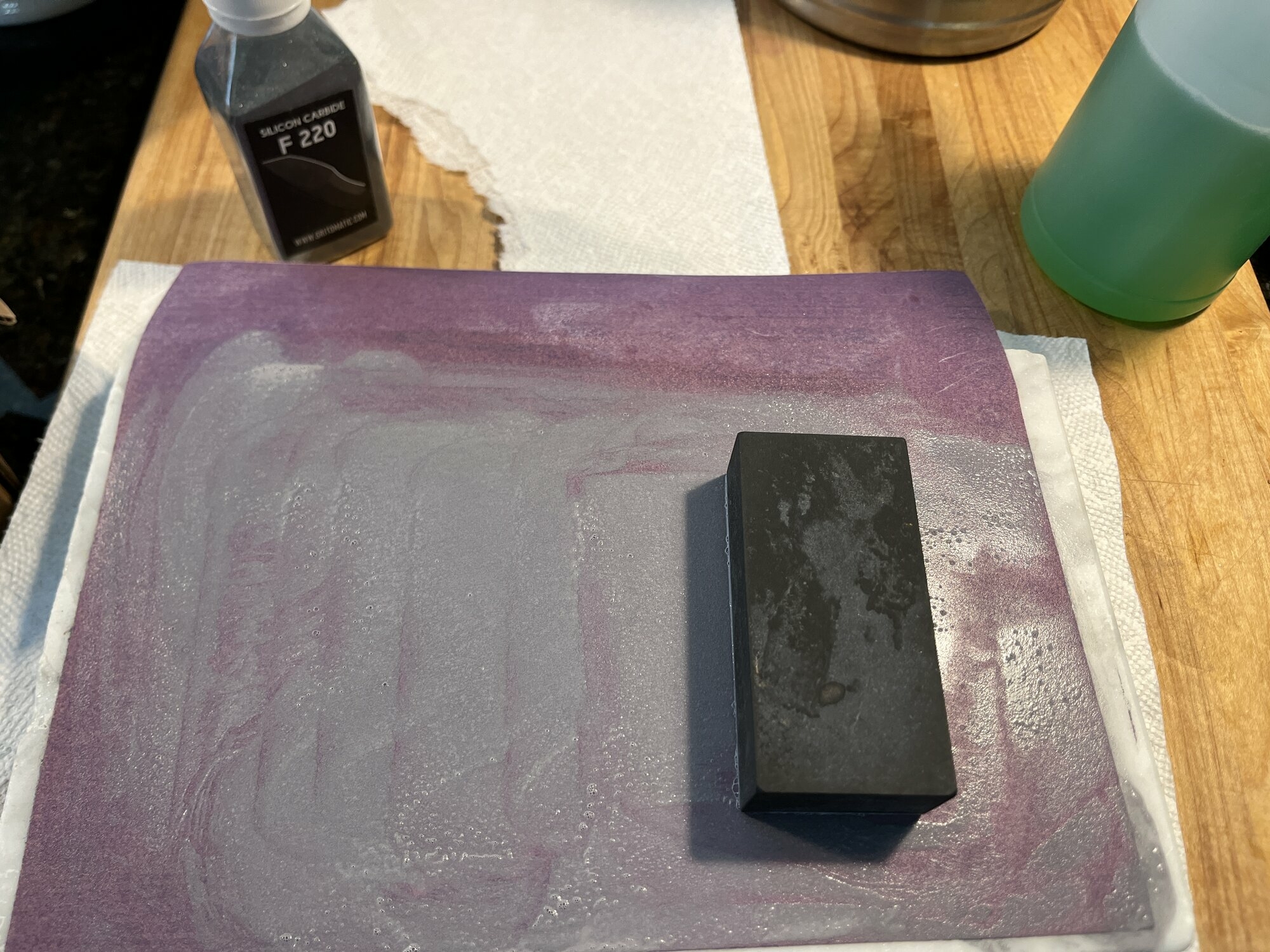

I've been working with a couple baggies of SiC powder I got from a kind knife forum guy. Recently invested in a full set, and it's definitely made things easier. You only need 1/4 - 1/2 tsp. of each grit for a stone this size.

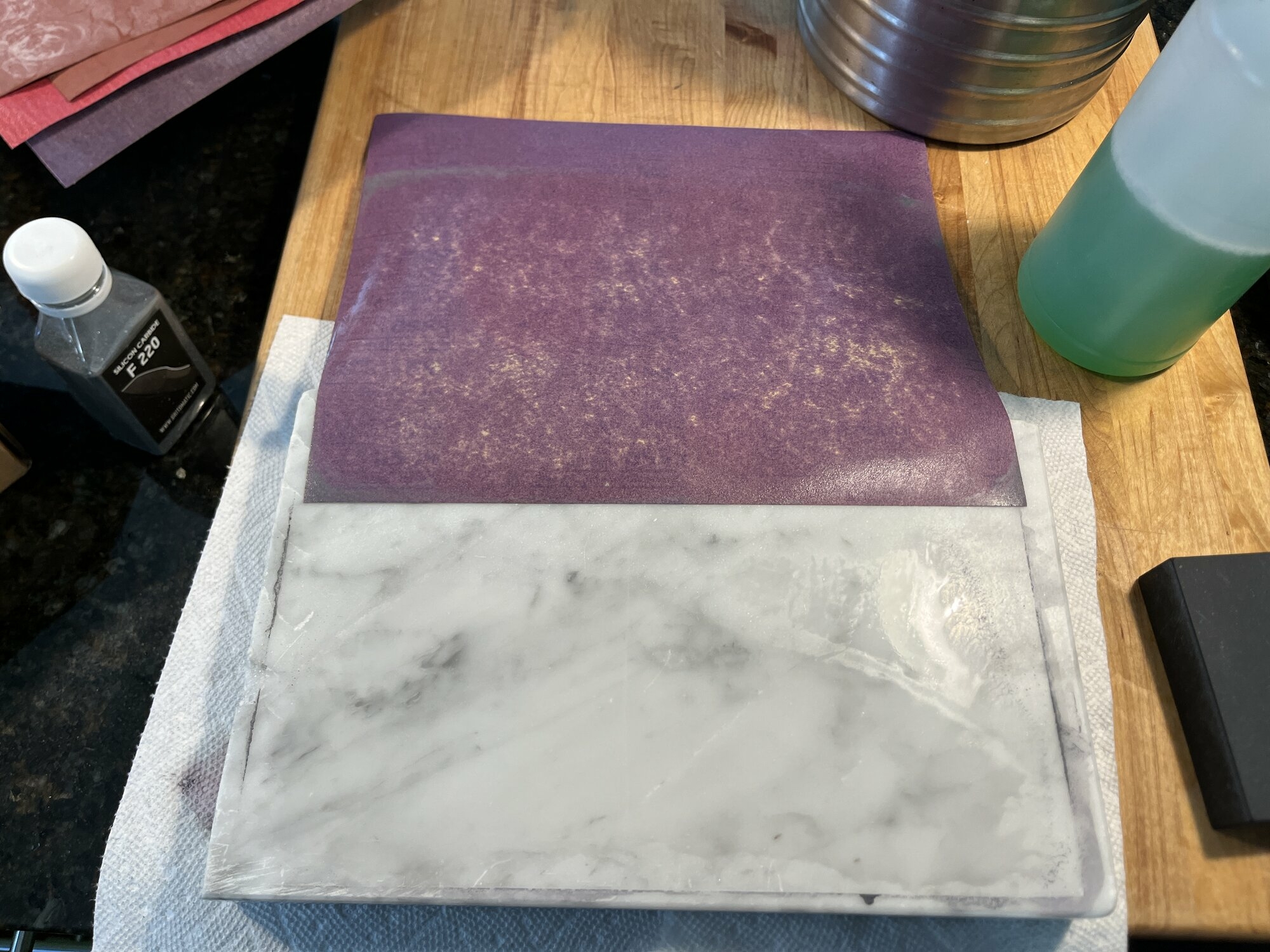

I like to use a dead-nutz flat marble counter offcut, with sacrificial high quality sandpaper to save the marble surface from dishing (Cubitron or Precision Pro Grade for coarse grits, Rhynowet for finer grits). These papers are incredibly durable, and I can lap many stones on a single sheet. I wet the back and front of the paper with Windex or some cleaner to make it adhere to the stone, prevent slipping, and lubricate the SiC powder.

What does the cutting speed depend on?

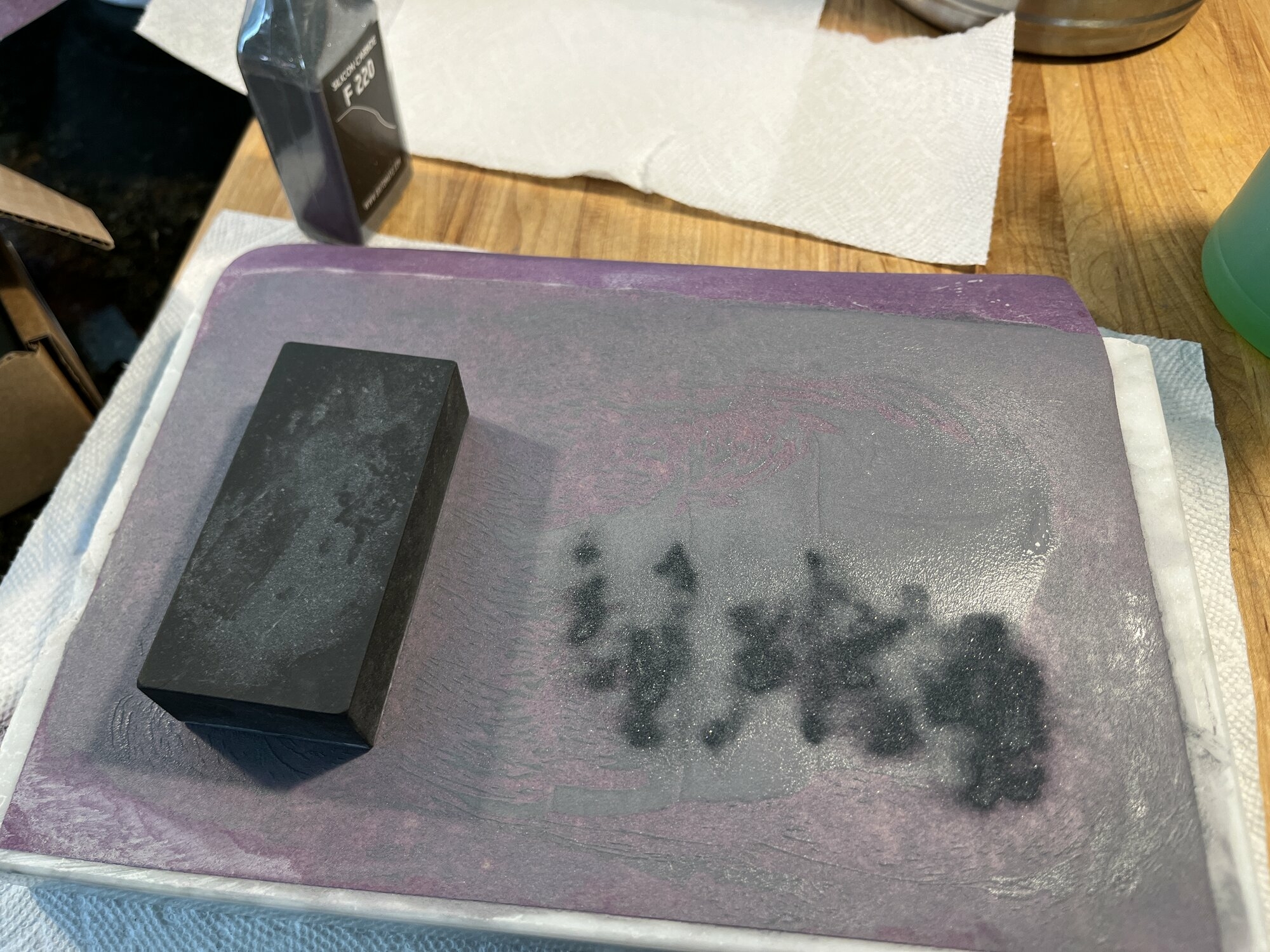

Note how much powder I'm using, how the surface changes at each grit, and how much more the finer grits will clump up, almost like clay.

120

220

I should have cleaned off the old powder first, oops.

Despite many uses, this Cubitron is still going strong

Today I'm dressing a hard black Ark with unknown branding, a $20 used tool store find that was finished very rough, maybe 36 grit on all surfaces when purchased. I was hoping I might luck into something like Keith Johnson's favorite, opaque black ark. This one is totally opaque, with some lighter figuring/veins much like the one he's fond of. I doubt this one is equal, but the search is always the fun part.

Anyway, here goes, and you can see how things change slowly along the way.

I've been working with a couple baggies of SiC powder I got from a kind knife forum guy. Recently invested in a full set, and it's definitely made things easier. You only need 1/4 - 1/2 tsp. of each grit for a stone this size.

I like to use a dead-nutz flat marble counter offcut, with sacrificial high quality sandpaper to save the marble surface from dishing (Cubitron or Precision Pro Grade for coarse grits, Rhynowet for finer grits). These papers are incredibly durable, and I can lap many stones on a single sheet. I wet the back and front of the paper with Windex or some cleaner to make it adhere to the stone, prevent slipping, and lubricate the SiC powder.

What does the cutting speed depend on?

- Sharp abrasive

- Pressure (the fraction of force divided by area, in a literal sense)

- Distance travelled over the abrasive

- Refresh your abrasive every so often, and clean off the old. You don't need much, but you want good contact between the stone and the loose grit. If you let a bunch of worn grit accumulate on the paper, fresh abrasive dulls itself on old abrasive. If you only use fresh, it'll cut faster. I don't have a recipe for how often - be observant.

- More pressure cuts faster, but too much can be destructive to the paper and the stone. Just be aware of how you angle the stone. Even 800 grit powder will round a sharp corner really quickly because of the small surface area. Work on keeping the stone flat, and not rocking it, since you can create a slight convex surface if you rock the stone, or have really thick SiC powder that doesn't allow flat lapping. Food for thought.

- Long, sweeping arcs/figure-8s will get things done quickly. Remember to keep things lubricated enough for easy SiC powder movement, since the grit needs to move freely over the surface to cut efficiently.

Note how much powder I'm using, how the surface changes at each grit, and how much more the finer grits will clump up, almost like clay.

120

220

I should have cleaned off the old powder first, oops.

Despite many uses, this Cubitron is still going strong

Last edited: