That's an interesting thought... could well be.

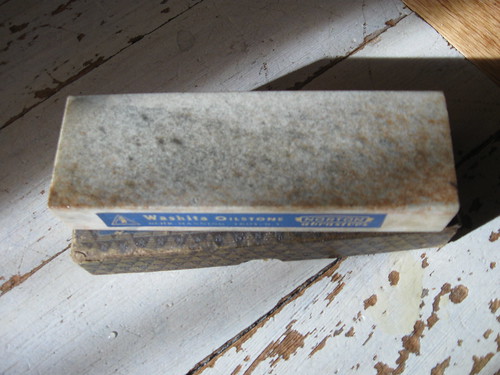

As DR said - they were supposedly like a particularly fast and coarse version of a LW, so they were white, but with a kinda pink/orange blush to parts of them (much like his picture above). Also had very low SGs, like 2 - 2.1. Whatever way - your new stone looks a good un to my eye

.

To confuse matters - there was also a 'Red Washita' which are the only labelled No.2 Grades I've ever seen. I don't exactly know why they called them that, but perhaps they had some of the coloured banding that Griswold calls Calico stones (?). I also don't know if the Red Washita Label existed in the US, the only ones I've seen come up were in the UK.

(Your stone looks far too homogenous to be a No.2 I'd have thought. Just an interesting fact for you!)