- Joined

- Dec 30, 2016

- Messages

- 1,973

- Reaction score

- 1,468

I think I remember seeing a thread on this before, but I’m wondering about it again. How do you all decide whether to call a knife thin behind the edge or not? Some are obviously so, like the lasers e.g. Shibata, and some are obviously not, like the German knives e.g. Wusthof. I’d say Mazaki are, and the Sukenari I’ve used are not. I judge based on how it feels and sounds going through onions, carrots, and sweet potatoes or yuca root if I have the latter two, and the height of the edge bevel (standardized 15* angle if I’m comparing or thinning).

But then there’s some ringers: the edge bevels on my Ikeda honyaki and Martell look like they’re not super thin behind the edge, but sure cut like they are; my Yukimitsu, no matter how much I thin it so far, looks like it barely has a microbevel but acts like it’s much thicker. Other features of the grind/blade geometry as a whole?

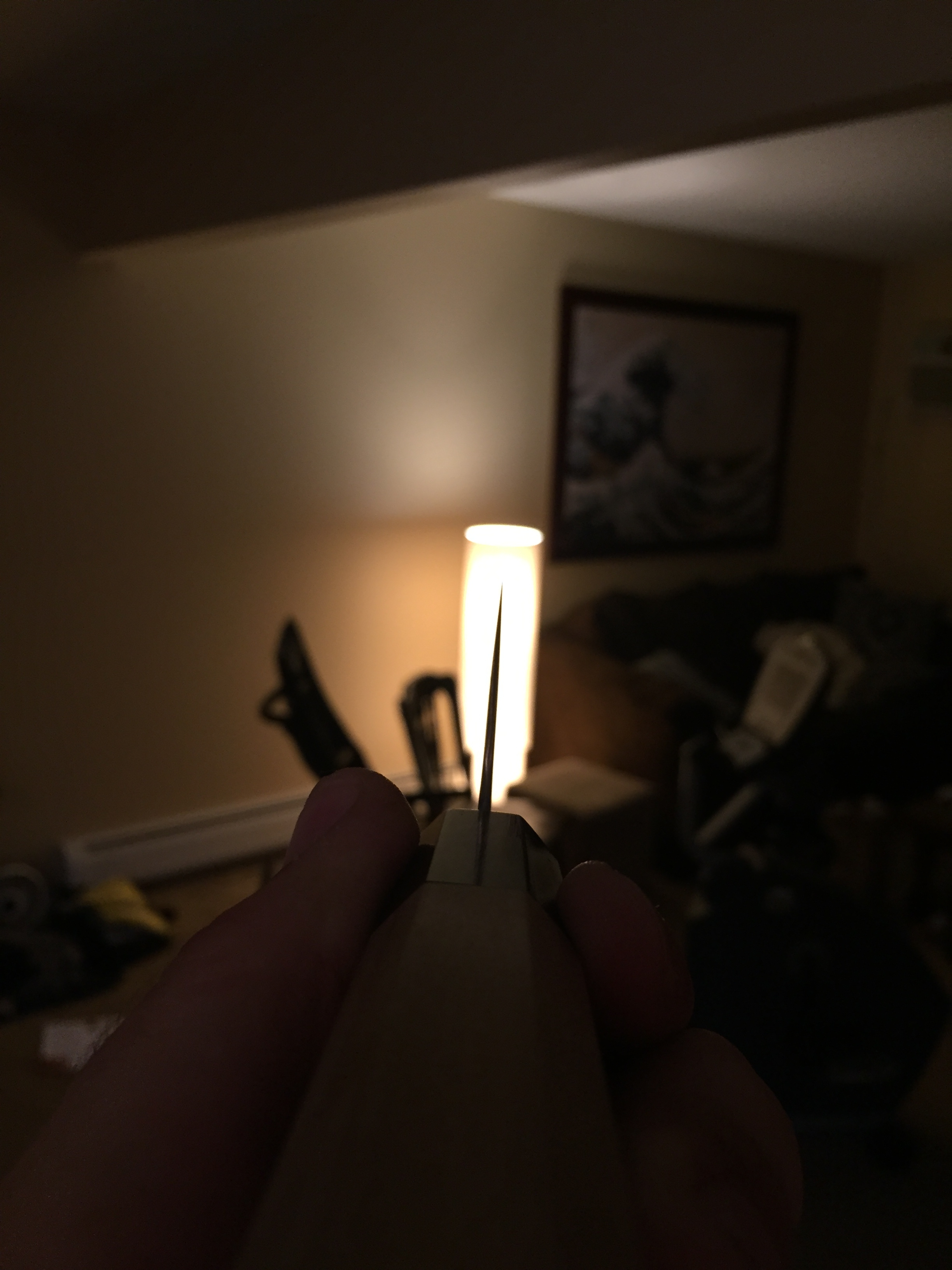

Finally, I got a Masakage Kujira from the recent batch. Thought at first it was like a good Takeda, turned out to be more like a bad Takeda. I always forget to take before shots, but the choil view looked like one I’ve seen of a Hiromune Takaba — good for a sword but not what I need in a kitchen. I decided I’d keep it as an expensive project knife and eventually learn how to refinish it too. Here are side and choil views of where I’m at. It’s quiet through carrots, doesn’t resist in Brussels sprouts and I’m happy with it, which means it probably needs one or two more sessions: what does the crowd think?

But then there’s some ringers: the edge bevels on my Ikeda honyaki and Martell look like they’re not super thin behind the edge, but sure cut like they are; my Yukimitsu, no matter how much I thin it so far, looks like it barely has a microbevel but acts like it’s much thicker. Other features of the grind/blade geometry as a whole?

Finally, I got a Masakage Kujira from the recent batch. Thought at first it was like a good Takeda, turned out to be more like a bad Takeda. I always forget to take before shots, but the choil view looked like one I’ve seen of a Hiromune Takaba — good for a sword but not what I need in a kitchen. I decided I’d keep it as an expensive project knife and eventually learn how to refinish it too. Here are side and choil views of where I’m at. It’s quiet through carrots, doesn’t resist in Brussels sprouts and I’m happy with it, which means it probably needs one or two more sessions: what does the crowd think?