I can’t quite figure out if this knife needs thinning or if it’s the finish causing suction that makes it hang up on onions. In the first video you can see it gets stuck doing horizontal cuts on onions, and also sometimes on the vertical cuts. But in the second video it has no problems with a sweet potato.

At the midpoint immediately behind the edge at 1mm it’s .22mm which seems a bit thick. But higher up at 5mm it’s .44mm and at 10mm it’s 1.0mm, which seem reasonable. So the measurements don’t seem excessive except for immediately BTE.

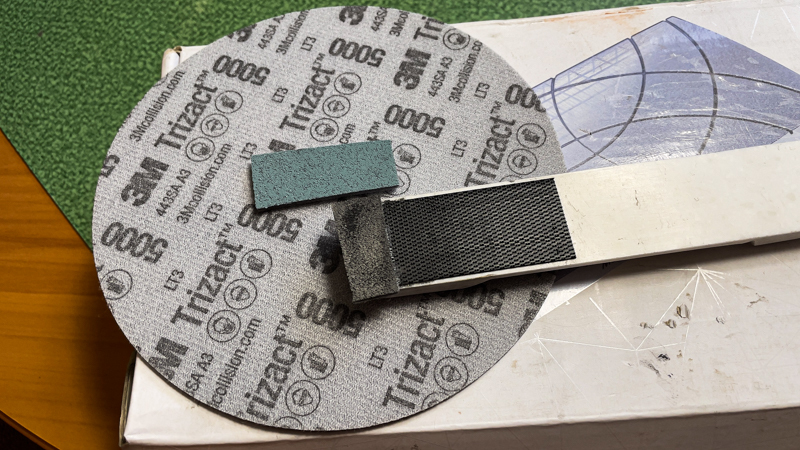

So should I thin a bit, or try some sandpaper first - and if so what grit? It’s a convex grind, so I wouldn’t normally expect suction to be much of an issue.

FYI @Matt Jacobs

At the midpoint immediately behind the edge at 1mm it’s .22mm which seems a bit thick. But higher up at 5mm it’s .44mm and at 10mm it’s 1.0mm, which seem reasonable. So the measurements don’t seem excessive except for immediately BTE.

So should I thin a bit, or try some sandpaper first - and if so what grit? It’s a convex grind, so I wouldn’t normally expect suction to be much of an issue.

FYI @Matt Jacobs