Thanks Jville, HRC_64 and Ragustoriches!

Quick update:

I've recently sold this knife to ashy2classy. I've tidied it up a bit, made a dedicated handle for it etc...

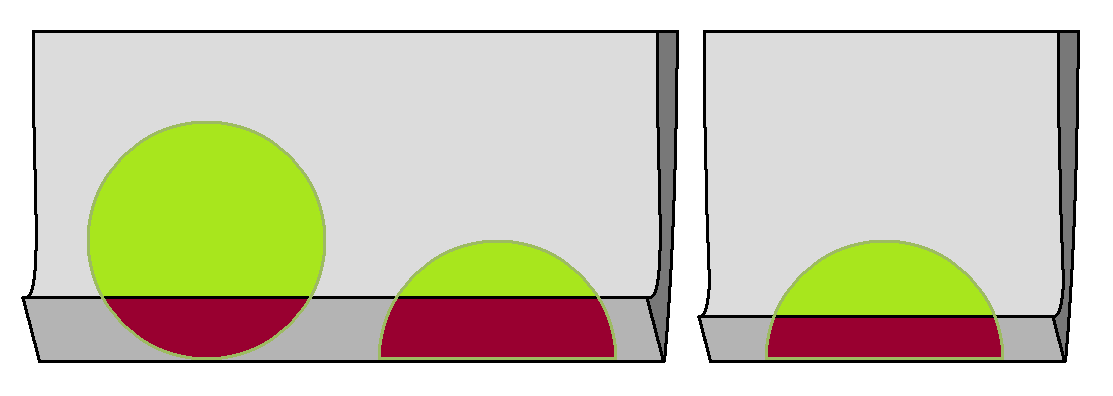

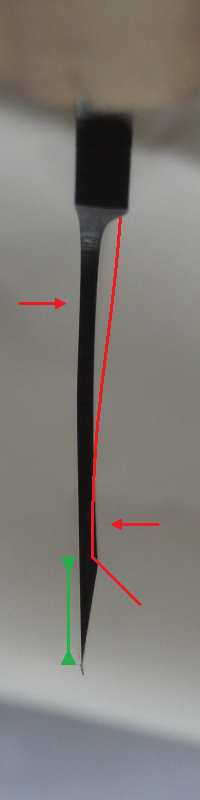

He preferred the choil to lean forward towards the tip, rather than curving back, so I changed it slightly:

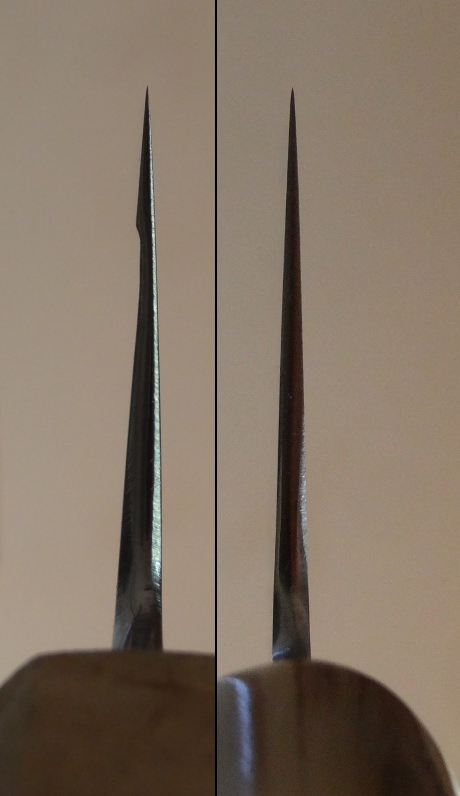

One thing I've realized; As of yet I've never done a straight-up comparison with another knife. I have access to a factory grind

Masamoto KS 250mm (shout-out to Marek07 for lending it to me), and I've recorded a quick video with them both in action with the hope it gives a better demonstration of just how much of a difference the 'hook' can make:

[video=youtube;0HGHpgg5HBs]https://www.youtube.com/watch?v=0HGHpgg5HBs[/video]

I gotta admit, when I go back to re-watch the video it looks like I'm using different techniques on each knife to encourage food to stick to the KS... I promise that's not the case at all. What's really happening is the food sticking to the KS changes the balance of the long and light knife with every cut. It throws the center of mass far forward making it harder to control and keep consistent rhythm, slowing me down (that's part of the appeal of the heavier workhorses, it's easier to ignore the changing weight of a heavier knife if food sticks to it). I also hate it when food falls

backwards into the path of the knife again, and gets randomly re-cut. I try to stop it from happening with the KS and it slows me right down.

When none of this is a problem I can really get into the groove and, instead of slowing down, I begin to speed up.

I love using this hook grind! It's a lot of fun to use and I should really should look into copying/repeating the results. It took many hours of back and forth testing between the grinder and the chopping board to get it to this stage. It's taught me a

huge amount about grinds in the process and there are probably a few people out there that wouldn't mind owning a knife like this for themselves.

I should also mention, when I said this earlier (in a different thread):

...my next project is a medium weight knife with the food release of a workhorse and the separation of a 'laser'...

Some people have referred to this, believing I've been working on another project, but in fact I was talking about the development of the knife in this thread. This grind is enough work as it is haha!