Kippington

A small green parrot

Hah so I've sobered up from last night's drinks and I have a few rambling thoughts to get out there.

But first I should apologize for a video that is 10 times longer then it needed to be. This was the first time I've done this kind of test and I got a little carried away! :laugh:

So considering stickage wasn't something I was thinking about when I re-profiled the knife, I think I did okay. It seems to go through a whole potato fine but starts sticking during the smaller slices.

One thing I regret not doing is testing it against the un-modified grind of the 240mm Sukenari which was sitting right next to me.

The tests brought up a few questions in my head too that maybe some of you can answer.

How thin can a knife be before it starts to become impossible to stop stickage (or whats the thinnest knife you have that you use on sticky foods)? The height of the knife would also come into play here. Also what foodstuff you decide to test-cut on, which brings me to another question...

What is your opinion on what an acceptable amount of stickage is? I mean there are foods that will always stick, no matter what. So what is the point at which you stop worrying about it? Potatoes seem to be the benchmark, but slicing potatoes in a way I've never needed as part of a dish before felt kinda strange... and yet at the same time I test cut paper for sharpness and smoothness on kitchen knives, and that's something I'll never need in a dish! :nah:

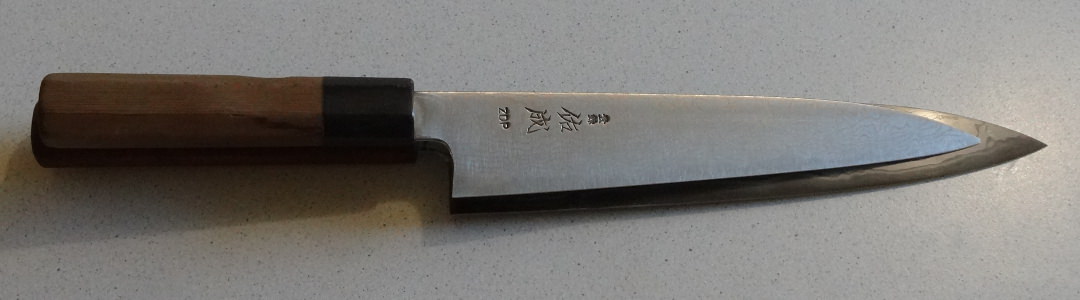

I'm going to leave this 270mm Sukenari as it is, but even so I'd like to learn a bit more for future reference.

I'd love to hear what you guys have to say about this!

But first I should apologize for a video that is 10 times longer then it needed to be. This was the first time I've done this kind of test and I got a little carried away! :laugh:

So considering stickage wasn't something I was thinking about when I re-profiled the knife, I think I did okay. It seems to go through a whole potato fine but starts sticking during the smaller slices.

One thing I regret not doing is testing it against the un-modified grind of the 240mm Sukenari which was sitting right next to me.

The tests brought up a few questions in my head too that maybe some of you can answer.

How thin can a knife be before it starts to become impossible to stop stickage (or whats the thinnest knife you have that you use on sticky foods)? The height of the knife would also come into play here. Also what foodstuff you decide to test-cut on, which brings me to another question...

What is your opinion on what an acceptable amount of stickage is? I mean there are foods that will always stick, no matter what. So what is the point at which you stop worrying about it? Potatoes seem to be the benchmark, but slicing potatoes in a way I've never needed as part of a dish before felt kinda strange... and yet at the same time I test cut paper for sharpness and smoothness on kitchen knives, and that's something I'll never need in a dish! :nah:

I'm going to leave this 270mm Sukenari as it is, but even so I'd like to learn a bit more for future reference.

I'd love to hear what you guys have to say about this!