THE GLASS CUTTING BOARD SHOWED AN INCREASE IN SHARPNESS THROUGH THE FIRST 400 TEST SLICES!

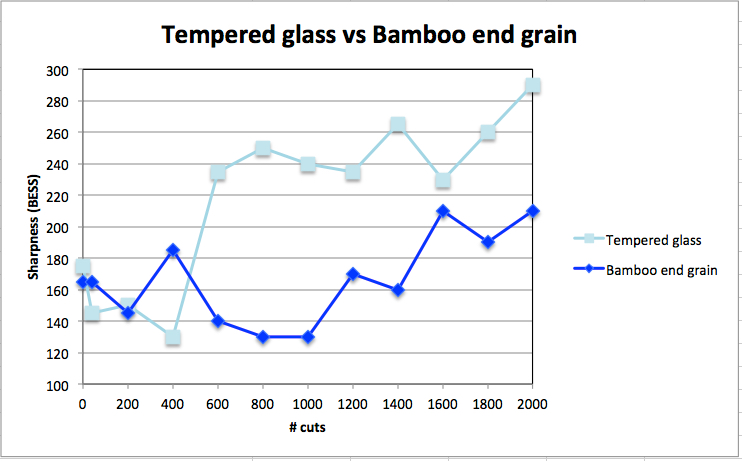

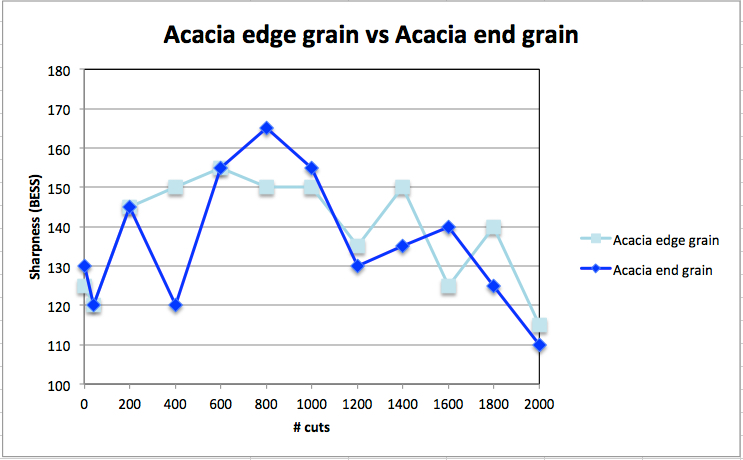

Look at the actual data and you'll see things that don't seem to make sense. I copied their data and made the following graphs from it.

From the graph above, you can see the sharpness (remember LOWER number = GREATER sharpness) after slicing on glass actually INCREASES during the first 400 slices. Excluding the outlier at 400 cuts, bamboo even shows increased sharpness through the first 1000 cuts!

Ok, how about the acacia wood edge grain versus end grain? From looking at just the starting sharpness versus the ending sharpness after 2000 cuts, what they show in the table on page 5, the sharpness gets better going from 125 to 115 for edge grain (long-grain in their words) or 130 to 110 for end grain. But the actual data shows a trend that seems to say they get duller through the first 800 cuts but then start to get sharper again!

Also, take note that the initial sharpness of the knives tested ranged from 120 to 195, so we are not comparing apples to apples to begin with.

The upshot to me is that there are some problems with measuring sharpness in their experiment. The data seem to show there may be errors in the precision of the measurement and/or errors in the accuracy, most likely both from the scatter and trends seen. The data given were averages of three readings, so we have no access to the raw data, only the averaged data. However, you can see that the sharpness seems to go up and down willy nilly. For example the acacia end grain sharpness swings up and down over a range of 35 points (120 to 155) through the first 600 cuts. Is the knife actually getting sharper then duller and then sharper and then duller again? It's possible... but not likely; therefore, it's more likely a problem with the sharpness measurement.

Looking at the sharpness testing apparatus and the manufacturer website, it looks like you cut a piece of test media (looks like some sort of plastic thread) which is threaded into a holder. Inconsistency of the test media could lead to scatter. Inconsistency with the tension applied to the media when strapped into the holder could also lead to scatter.

All in all, from the data the conclusion I would be willing to draw is that there may be some dulling when cutting on tempered glass, but otherwise the data is not of high enough quality to otherwise draw many conclusions. Multiple data points on each cutting board should be made, i.e. multiple knives tested per cutting board material versus just one knife per material, and perhaps multiple (more than the 3 used in this experiment) sharpness measurements per data point.