Keith Sinclair

Senior Member

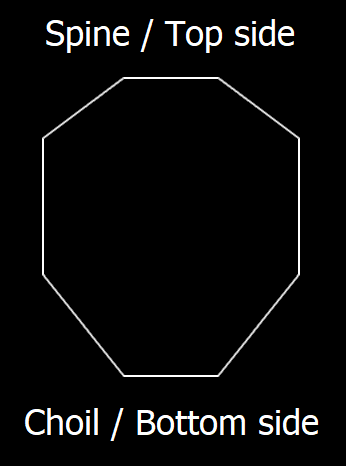

How do you cut in your 45% bevels.

When was helping Stefan Keller I made handles for my knives. Also some for students at culinary school. He had the tools in his shop. A big disk sander set table at 45% & grind checking as you go. That thing made me a little nervous did do about a dozen handles on it.

He also had a jig used with bandsaw I liked that better.

I have a table drill press & 1/42 belt sander that have used for all kinds of stuff. With these can make western scale knife handles & oval wa handles. Hardly make handles anymore. Just curious different ways folks cut 45% for wa octagons.

Oval out of African blackwood & Spalted Hawaiian Signature wood. Made for my trusty iron clad Watanabe. Just thinking about this makes me miss Stefan we had some good times.

When was helping Stefan Keller I made handles for my knives. Also some for students at culinary school. He had the tools in his shop. A big disk sander set table at 45% & grind checking as you go. That thing made me a little nervous did do about a dozen handles on it.

He also had a jig used with bandsaw I liked that better.

I have a table drill press & 1/42 belt sander that have used for all kinds of stuff. With these can make western scale knife handles & oval wa handles. Hardly make handles anymore. Just curious different ways folks cut 45% for wa octagons.

Oval out of African blackwood & Spalted Hawaiian Signature wood. Made for my trusty iron clad Watanabe. Just thinking about this makes me miss Stefan we had some good times.