@ian

To complete what I was saying in the previous post. I was just talking about how evening a bevel can increase performance by reducing friction, more than by the fact the bevel is thinned in the process.

For exemple, I believe a thicker knife, with good geometry and even bevels can cut better than a thinner knife that is not straight and even. Then you say, is the thicker knife capable of better performance than the thin one with even geometry ? I may say for most kitchen task the thinner one may cut better in some food, but not sure about all tasks and it also depends what we call performance : everytime we talk about this we use words like smoothness, ease of cutting, feeling of cutting, edge retention, non stickyness. Those are mostly subjectives as we all have different experiences in our kitchen, cutting on different support with different technique and cutting different food for different purposes.

But yeah, I think evening a bevel is doing both actually : evening and thinning, so both help for better performance. Is thinning helping more than evening, my side I am not sure.

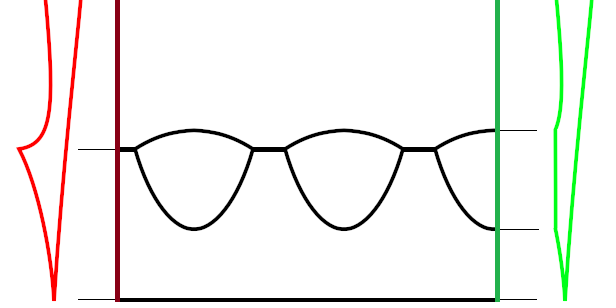

Then, if we talk about friction, lot of people will think about s, c, hook grinds. Saying that you can grind concavities on a convex geometry knife will give it much better anti-friction capacities. Yeah they may help, they may do wonders. But it is not the subject really. I was just commenting how evening a knife (what ever the geometry and the tool) deal with friction, so help with performance. Which grind is best, why you prefer that knife to an other, why you prefer the anti friction effect of a s grind compared to the anti friction effect of convex grind : all this is personal taste. Like people who prefer driving a ferrari or a old 50's peugeot. There will be pleasure in both case and in both case, both cars performs as good as they were design for. You may go faster in a ferrari and have better sensations, but you may enjoy the landscape better and meet more people along the road with your old peugeot. Depends why you drive.