- Joined

- Mar 3, 2020

- Messages

- 874

- Reaction score

- 1,033

Is that the tall nakiri or the cleaver?Getting ready for the big day: Moritaka and SG500

CleaverIs that the tall nakiri or the cleaver?

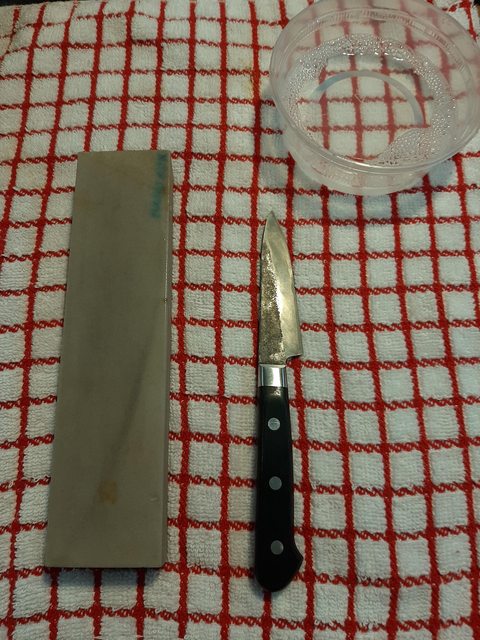

Nice Rocks.Wasting my day off waiting for a service tech at the restaurant. Figured I might as well bring my toys with me.

View attachment 212120

What stone are you Using to flatten the bevels?Battle with my Yaoke is still not over, but I think I'm starting to pull ahead. Started out with a 0.45mm edge thickness and a massive hollow. Just a few more low spots remain.

View attachment 215890View attachment 215891

JNS 300. I like this stone a lot. Doesn't dish too bad, refreshes grit on its own, and it's huge so I don't see myself using it up ever.What stone are you Using to flatten the bevels?

Finally, both bevels are fully convex. Arms are tired now, gotta save polishing for another day.Battle with my Yaoke is still not over, but I think I'm starting to pull ahead. Started out with a 0.45mm edge thickness and a massive hollow. Just a few more low spots remain.

Bless y’all that polish. I can’t imagine it, but I still need work on my sharpening, so it isn’t really relevant.

Those scratches look good, I have to try that JNS 300 when my SG220 wears out...Finally, both bevels are fully convex. Arms are tired now, gotta save polishing for another day.

View attachment 216003

I prefer it over my sg220. The 220 feels like it dishes too fastThose scratches look good, I have to try that JNS 300 when my SG220 wears out...

Nakayama koppa around 7-10kHow did you finish that soft, stainless cleaver?

Another day, another couple hours. Also fully rounded and polished the spine and choil.Finally, both bevels are fully convex. Arms are tired now, gotta save polishing for another day.

Damn, sir. Unbelievable skills.Another day, another couple hours. Also fully rounded and polished the spine and choil.

View attachment 216525

Talk to me about the finish on this one! Progression, etc. love the texture under the KUAnother day, another couple hours. Also fully rounded and polished the spine and choil.

View attachment 216525

Awesome!Another day, another couple hours. Also fully rounded and polished the spine and choil.

View attachment 216525

Actually this is just the base polish with king 800. The finish actually sucks to use, so I plan to progress to other stones tomorrow.Talk to me about the finish on this one! Progression, etc. love the texture under the KU

Looks amazing. This may be a stupid question but something I haven't considered. When polishing/removing material on wide bevels...how do you achieve convexity vs just having the grind become full flat? I feel like over time thinning or even reprofiling, the bevels would lose the convexity and they would turn flat.Another day, another couple hours. Also fully rounded and polished the spine and choil.

View attachment 216525

Enter your email address to join: